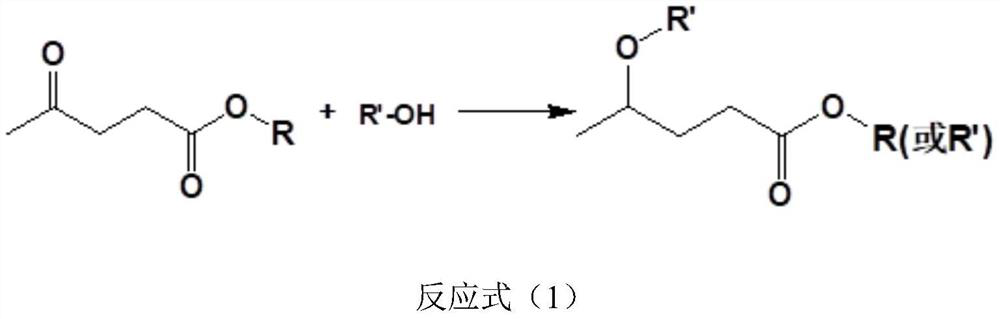

Method and supported catalyst for preparing 4-alkoxyvalerate by liquid-phase hydrogenation

A technology of supported catalyst and alkoxyvalerate, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, molecular sieve catalyst, catalyst activation/preparation, etc., can solve the problem of high cost and achieve simple operation and high energy efficiency. The effect of low consumption and high yield of target product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 supported palladium catalyst:

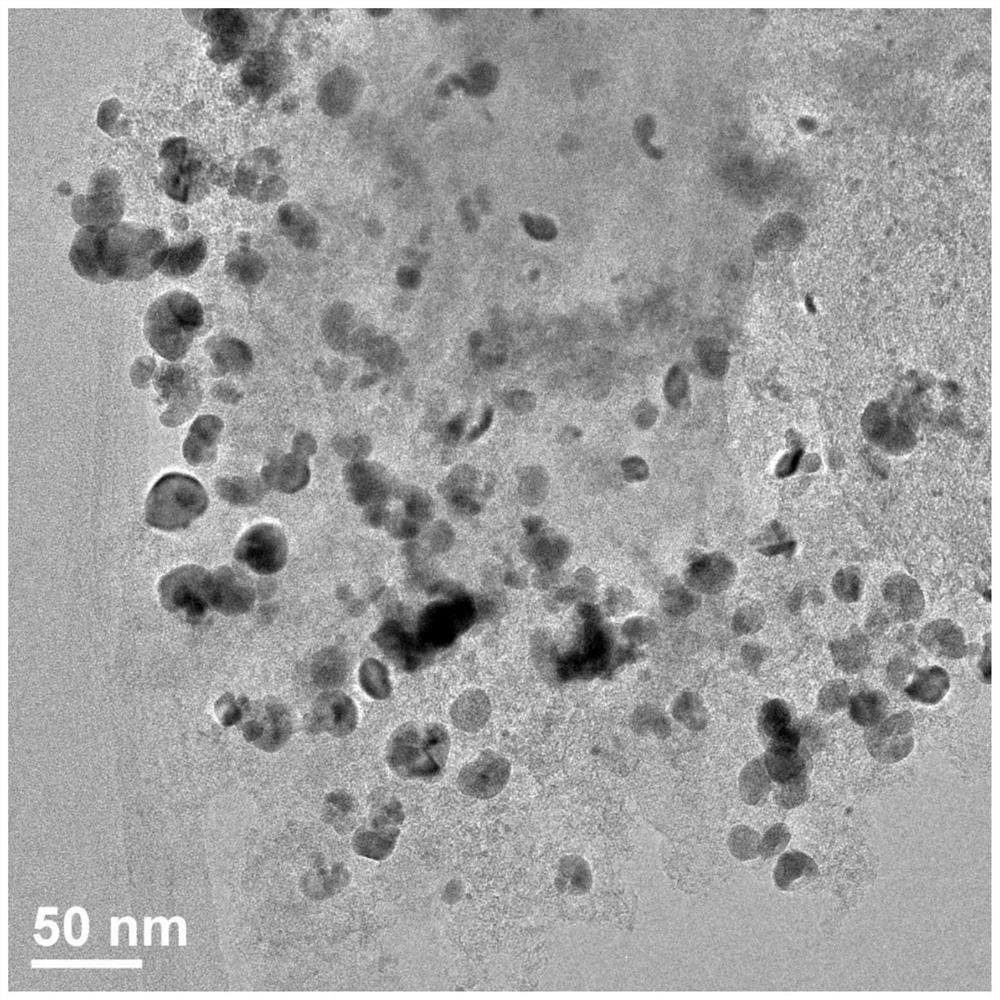

[0043] Disperse the carrier activated carbon evenly in the aqueous solution, and take an appropriate amount of PdCl according to the required mass ratio 2 The solution was added to the carrier aqueous solution, stirred evenly at room temperature and then adjusted to pH Pd 2+ Precipitation is complete, add sodium borohydride (Pd 2+ : Sodium borohydride=1:15, mol ratio) and continued to stir for 2 hours. The gained solution is filtered and dried, and the supported palladium catalyst is prepared, and the palladium metal nanoparticles are evenly distributed on the carrier (as attached figure 1 shown).

[0044]Sodium borohydride is used as reducing agent in this embodiment. In the method of the present invention, in other embodiments, the reducing agent can also be hydrazine hydrate or hydrogen, both of which can achieve the same effect.

Embodiment 2

[0045] Example 2 Loaded Pd-SiO 2 Preparation of / C catalyst:

[0046] First, weigh 1g of activated carbon, disperse it evenly in the ethanol solution, measure the required amount of tetraethyl orthosilicate as the silicon source, drop it into the activated carbon solution drop by drop, stir for 12 hours, and wait until the tetraethyl orthosilicate is completely hydrolyzed. Suction filtration, drying in an oven at 80°C for 12h, and then taking it out and putting it into a tube furnace for calcination at 500°C for 2h with a heating rate of 3°C / min. Get SiO 2 / C, with this as a carrier, the same method as in Example 1 supports metal palladium.

[0047] In this example, tetraethyl orthosilicate was used to prepare the silica-modified carrier. In other embodiments, supports modified by common oxides such as cerium oxide, aluminum oxide, titanium oxide, and niobium oxide can also be prepared, and the same method is used to prepare supported catalysts.

[0048] Sodium borohydride...

Embodiment 3

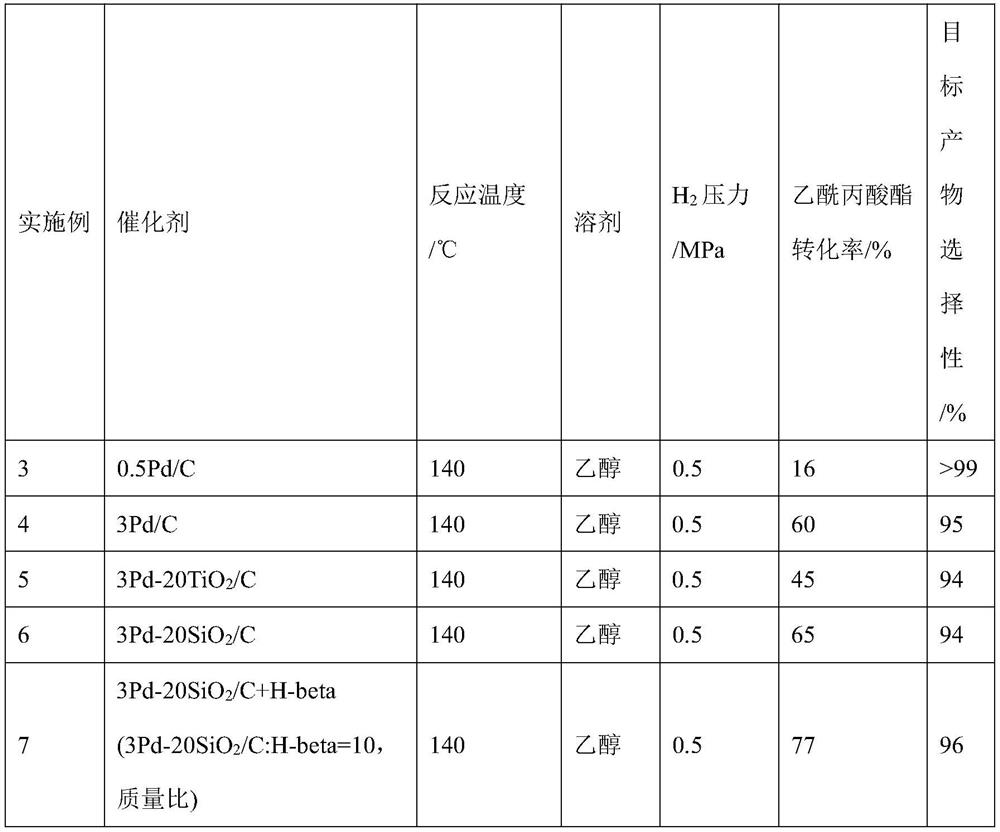

[0049] Embodiment 3 ethyl levulinate hydrogenation reaction

[0050] Use the catalyst prepared in Example 1 to prepare ethyl 4-ethoxyvalerate by liquid-phase hydrogenation of ethyl levulinate, and load catalyst 0.5Pd / C (Pd:C=0.5% in a 100ml reactor lining) , mass ratio), the consumption is about 15% (accounting for ethyl levulinate mass percent), adding raw material ethyl levulinate, solvent ethanol, the solvent dilution ratio is about 30:1 (ethanol: ethyl levulinate, volume ratio), the reaction temperature was 140°C, and the reaction was carried out for 4 hours under a hydrogen pressure of 0.5 MPa, the conversion rate of ethyl levulinate was 16%, and the selectivity of the target product was >99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com