Method for continuously producing rare-earth sulfide coloring agent in large scale

A rare earth sulfide and rare earth compound technology, which is applied in chemical instruments and methods, dyeing low molecular organic compound treatment, dyeing physical treatment, etc. problem, to achieve the effect of low cost, high production efficiency and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

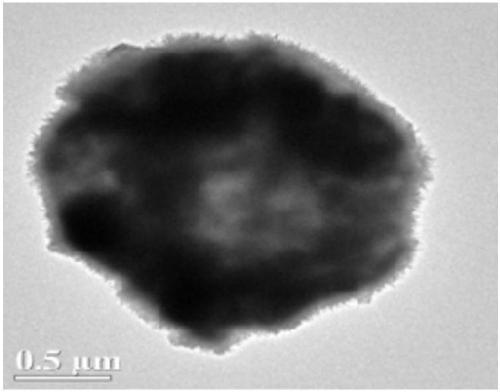

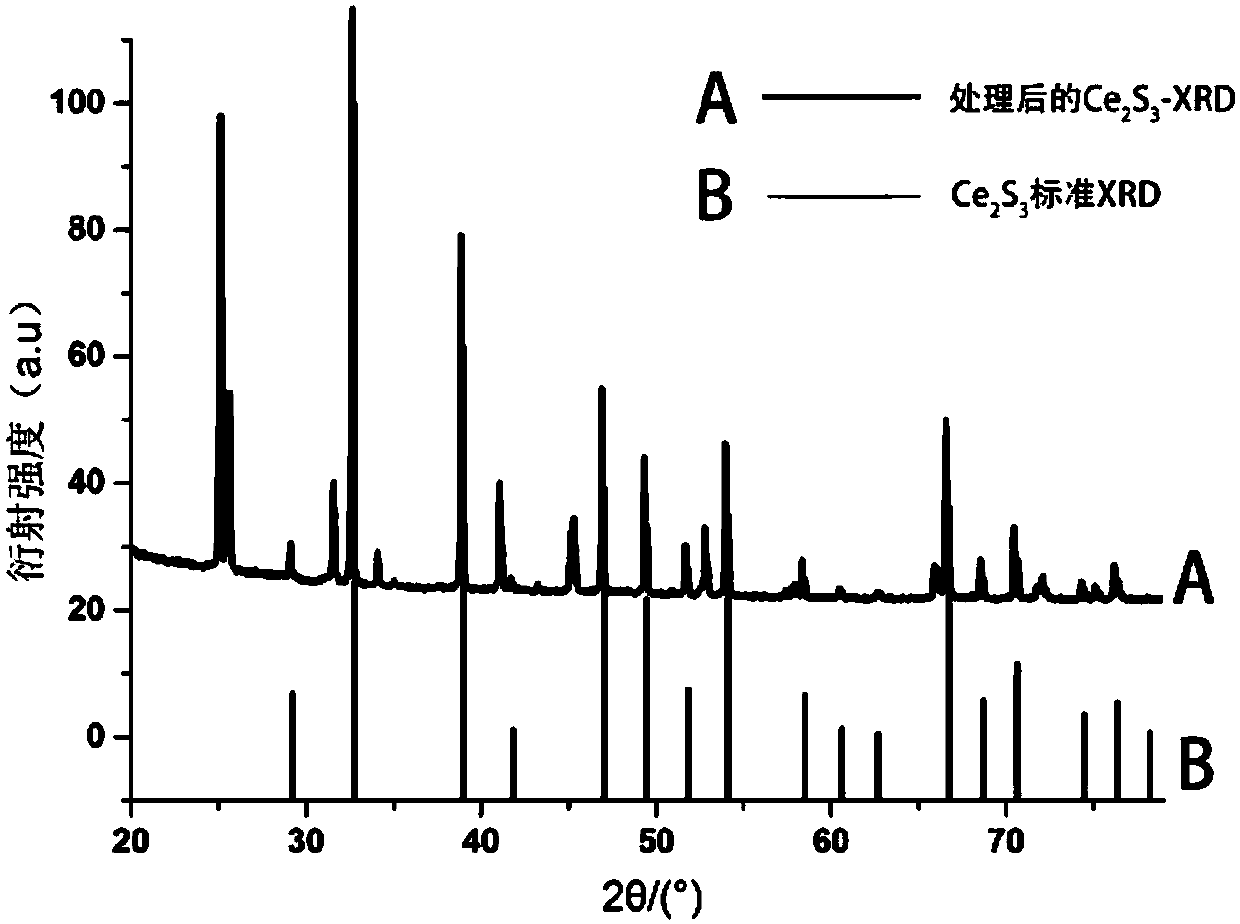

[0033] This embodiment provides a method for continuous large-scale production of cerium sulfide colorant, comprising the following steps:

[0034] (1) Get 0.05mol cerium carbonate, 0.15mol sulfur, 0.003mol lithium carbonate, 0.3mol solid carbon and 0.033mol aluminum fluoride and place them in a crucible, put them into a pusher kiln for reaction, and set the temperature of the pusher kiln to be 800 ℃, high-temperature zone for 2400min roasting reaction, the first product of cerium sulfide colorant is obtained;

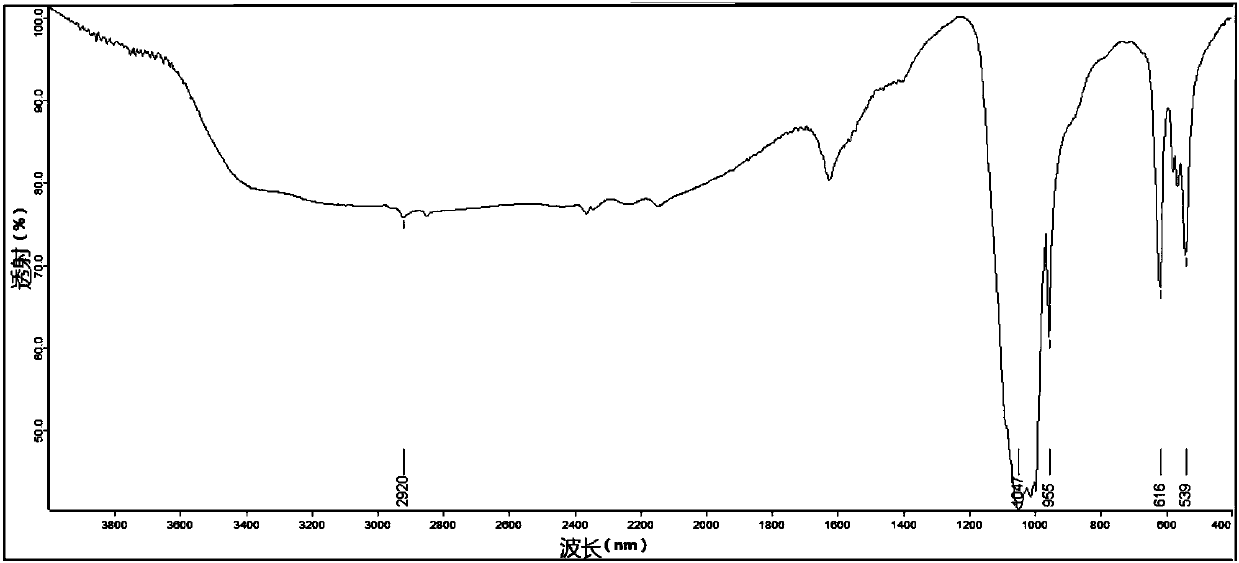

[0035] (2) After adding water to the initial product of the sulfide cerium sulfide and cleaning it 3 times, then add 2 times of quality water to prepare a suspension;

[0036] (3) Add magnesium stearate, sodium silicate, zirconium oxychloride, and zinc dihydrogen phosphate to the suspension, mix well and adjust the pH to 2, stir and react at 0°C for 10 hours, and then perform solid-liquid separation. The solid phase is dried at 20°C for 24 hours to obtain the cerium s...

Embodiment 2

[0042] This embodiment provides a method for continuous large-scale production of cerium sulfide colorant, comprising the following steps:

[0043] (1) Take 0.05mol of lanthanum carbonate, 0.35mol of sulfur, 0.015mol of sodium carbonate, 5mol of solid carbon and 0.005mol of sodium fluoride in a crucible, put them into a pusher kiln for reaction, and set the temperature of the pusher kiln to 1500°C , the high-temperature zone was roasted for 20 minutes to obtain the primary product of cerium sulfide colorant;

[0044] (2) After adding water to the initial product of the cerium sulfide colorant and cleaning it 3 times, then add 20 times of quality water to prepare a suspension;

[0045](3) Add calcium stearate, sodium silicate, zirconium oxychloride, and aluminum dihydrogen phosphate to the suspension, mix well and adjust the pH to 12, stir and react at 140°C for 1 hour, and then perform solid-liquid separation. The solid phase was dried at 400° C. for 0.5 h to obtain the ceriu...

Embodiment 3

[0047] This embodiment provides a method for continuous large-scale production of cerium sulfide colorant, comprising the following steps:

[0048] (1) Get 0.05mol cerium oxide, 0.2mol sulfur, 0.015mol lithium carbonate, 2mol solid carbon and 0.01mol ammonium fluoride to be placed in the crucible, put into the pusher kiln and react, the temperature of the pusher kiln is set to 1000°C, 1200min roasting reaction in the high temperature zone to obtain the primary product of cerium sulfide colorant;

[0049] (2) After adding water to the initial product of the cerium sulfide colorant and cleaning it 3 times, then adding 10 times the quality of water to prepare a suspension;

[0050] (3) Add calcium stearate, sodium silicate, zirconium silicate, and boron dihydrogen phosphate to the suspension, mix well and adjust the pH to 8, stir and react at 80°C for 6 hours, and then perform solid-liquid separation. The solid phase is dried at 60°C for 5 hours to obtain the cerium sulfide colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com