Method for preparing erythrothioneine-containing cosmetic stock solution through hericium erinaceus fermentation

A technology of ergothioneine and Hericium Hericium, which is applied in the direction of cosmetics, cosmetic preparations, and methods based on microorganisms. It can solve the problems of low ergothioneine content, active ingredient application, and insufficient preparation of products that meet the requirements of cosmetic specifications, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

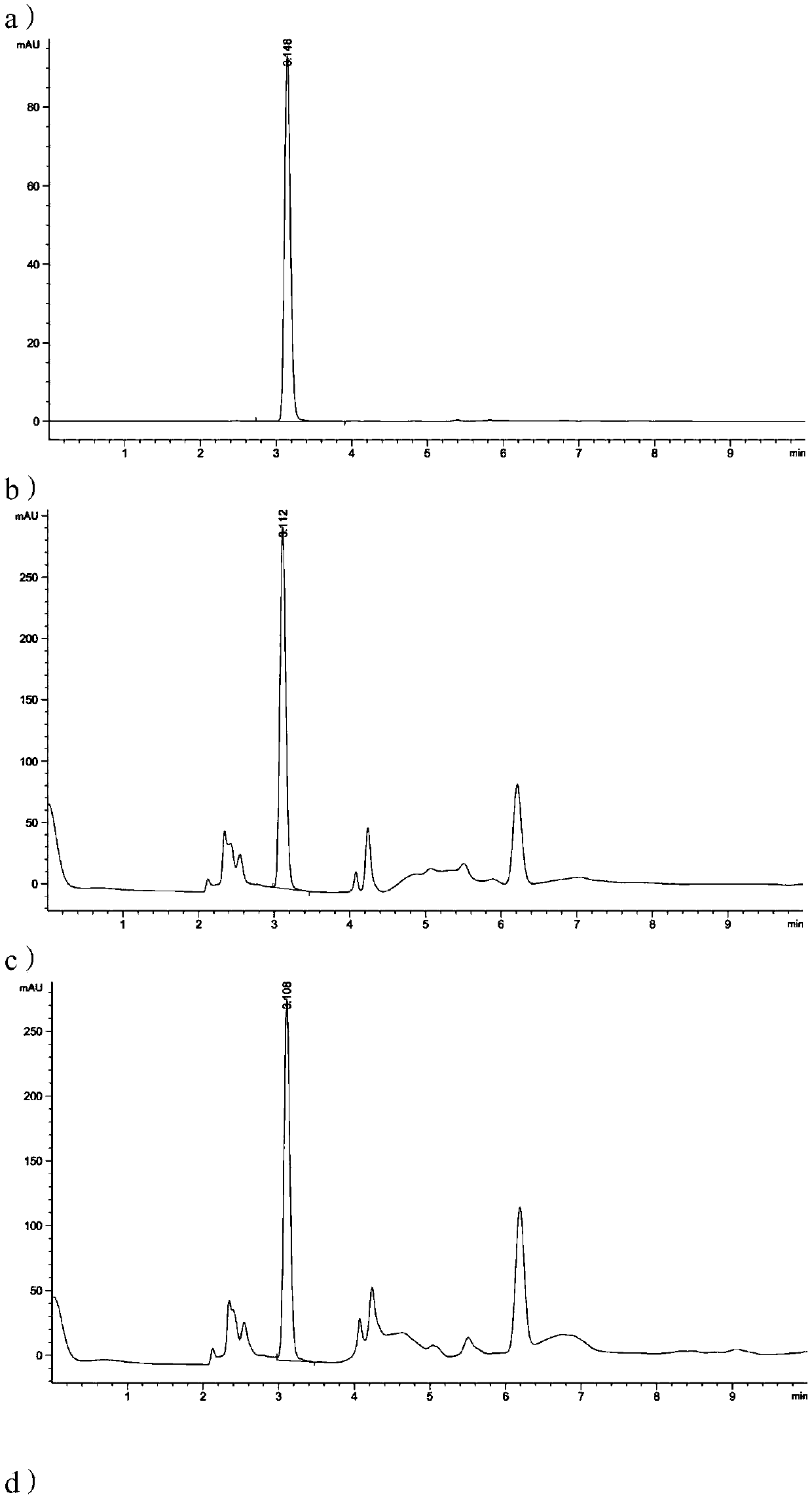

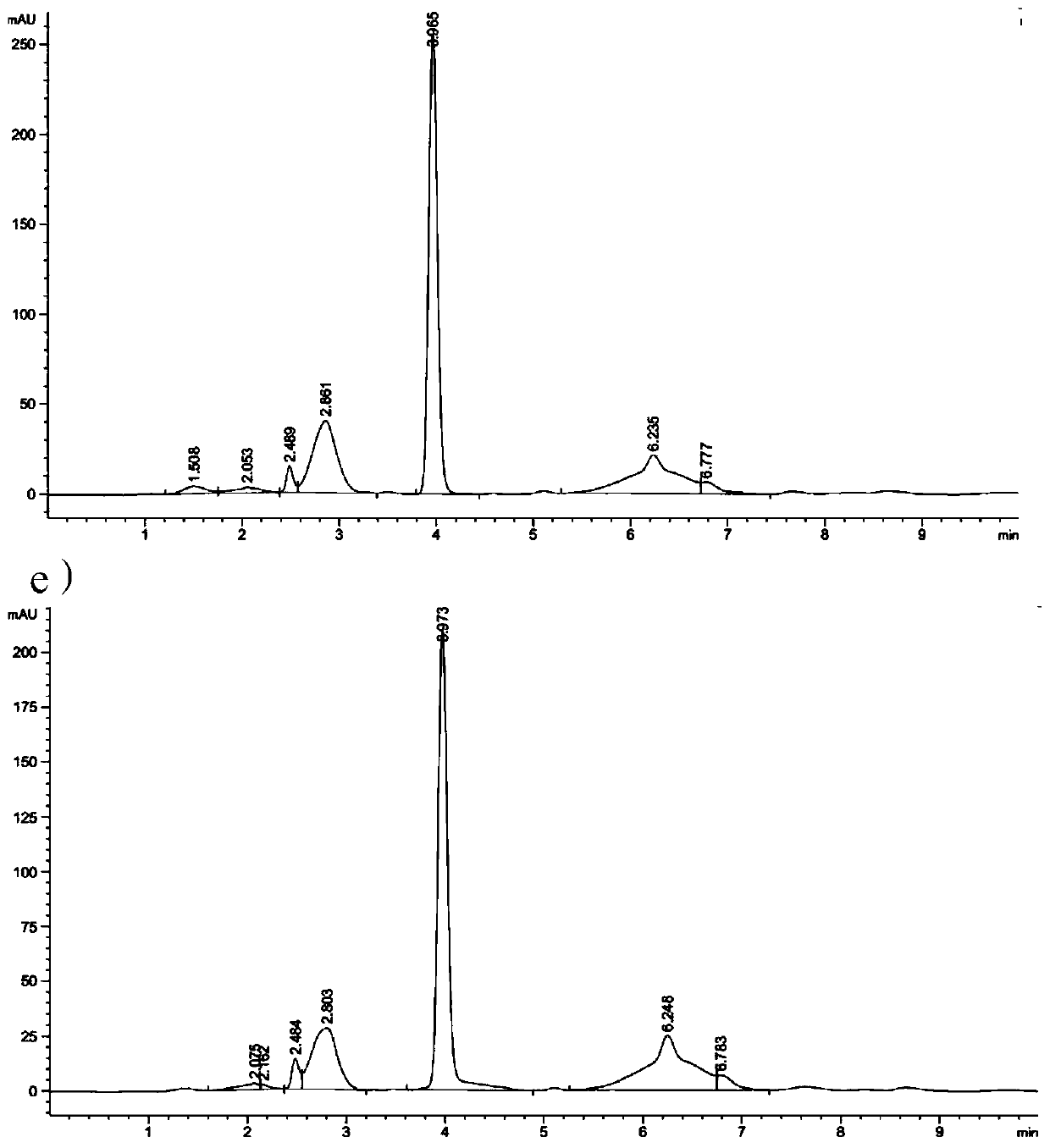

Image

Examples

Embodiment 1

[0114] (1) Preserved strains in test tubes were inoculated into 100ml of seed culture medium with bacterial blocks, and cultured at 25°C for 5 days on a shaker at 150rpm;

[0115] The composition of the seed medium is as follows:

[0116] Sucrose 20g / L, bean cake powder 15g / L, sodium sulfate 0.5g / L, disodium hydrogen phosphate 0.5g / L, acetic acid to adjust the pH to 5.0.

[0117] (2) Seed medium was inoculated into 1L fermentation medium, 200rpm shaker, 25°C fermentation culture for 10 days until no residual sugar;

[0118] The composition of the fermentation medium is as follows:

[0119] Glycerin 25g / L, beef extract 20g / L, sodium sulfate 1g / L, disodium hydrogen phosphate 1g / L, zinc chloride 0.005g / L, pyridoxal phosphate 0.001g / L, acetic acid to adjust pH to 5.0, aspartic acid Acid 10mM, Glutamine 5mM, Betaine 10Mm;

[0120] (3) Fermentation liquid is through homogenization 30min, homogenization rotating speed is 3000rpm / min, then through ultrasonic 15min, ultrasonic power...

Embodiment 2

[0122] (1) Inoculate the bacteria block into 200ml seed culture medium for the strains preserved in test tubes, culture at 25°C for 7 days on a shaker at 200rpm;

[0123] The composition of the seed medium is as follows:

[0124] Glucose 25g / L, bean cake powder 15g / L, sodium sulfate 0.5g / L, disodium hydrogen phosphate 0.5g / L, acetic acid to adjust pH to 5.5

[0125] (2) Seed culture medium was inoculated into 2L fermentation medium, shaken at 200 rpm, and fermented at 25°C for 9 days until there was no residual sugar;

[0126] The composition of the fermentation medium is as follows:

[0127] Glycerin 25g / L, beef extract 20g / L, sodium sulfate 0.75g / L, disodium hydrogen phosphate 1g / L, zinc chloride 0.005g / L, pyridoxal phosphate 0.001g / L, acetic acid to adjust pH to 5.5, asparagus Amino acid 8mM, glutamine 5mM, betaine 15Mm;

[0128] (3) fermented liquid is through homogenizing 40min, and homogenizing rotating speed is 3000rpm / min, then through ultrasonic 30min, ultrasonic p...

Embodiment 3

[0130] (1) Inoculate the bacteria block into 500ml seed culture medium for the strains preserved in test tubes, and incubate at 30°C for 8 days on a shaker at 150rpm;

[0131] The composition of the seed medium is as follows:

[0132] Maltose 50g / L, beef extract 35g / L, potassium chloride 0.75g / L, disodium hydrogen phosphate 0.5g / L, lactic acid to adjust the pH to 4.5.

[0133] (2) Seed medium was inoculated into 5L fermentation medium, 100rpm shaker, 30°C fermentation culture for 15 days until no residual sugar;

[0134] The composition of the fermentation medium is as follows:

[0135] Glycerin 50g / L, peptone 30g / L, sodium dihydrogen phosphate 1g / L, disodium hydrogen phosphate 1g / L, ferrous chloride 0.0075g / L, vitamin B120.002g / L, acetic acid to adjust pH to 4.5, aspartic acid Acid 10mM, Glutamine 5mM, Betaine 15Mm;

[0136] (3) fermented liquid is through homogenizing 30min, and homogenizing rotating speed is 3000rpm / min, then through ultrasonic 45min, ultrasonic power is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com