Metal lithium negative electrode material, as well as preparation method and application thereof

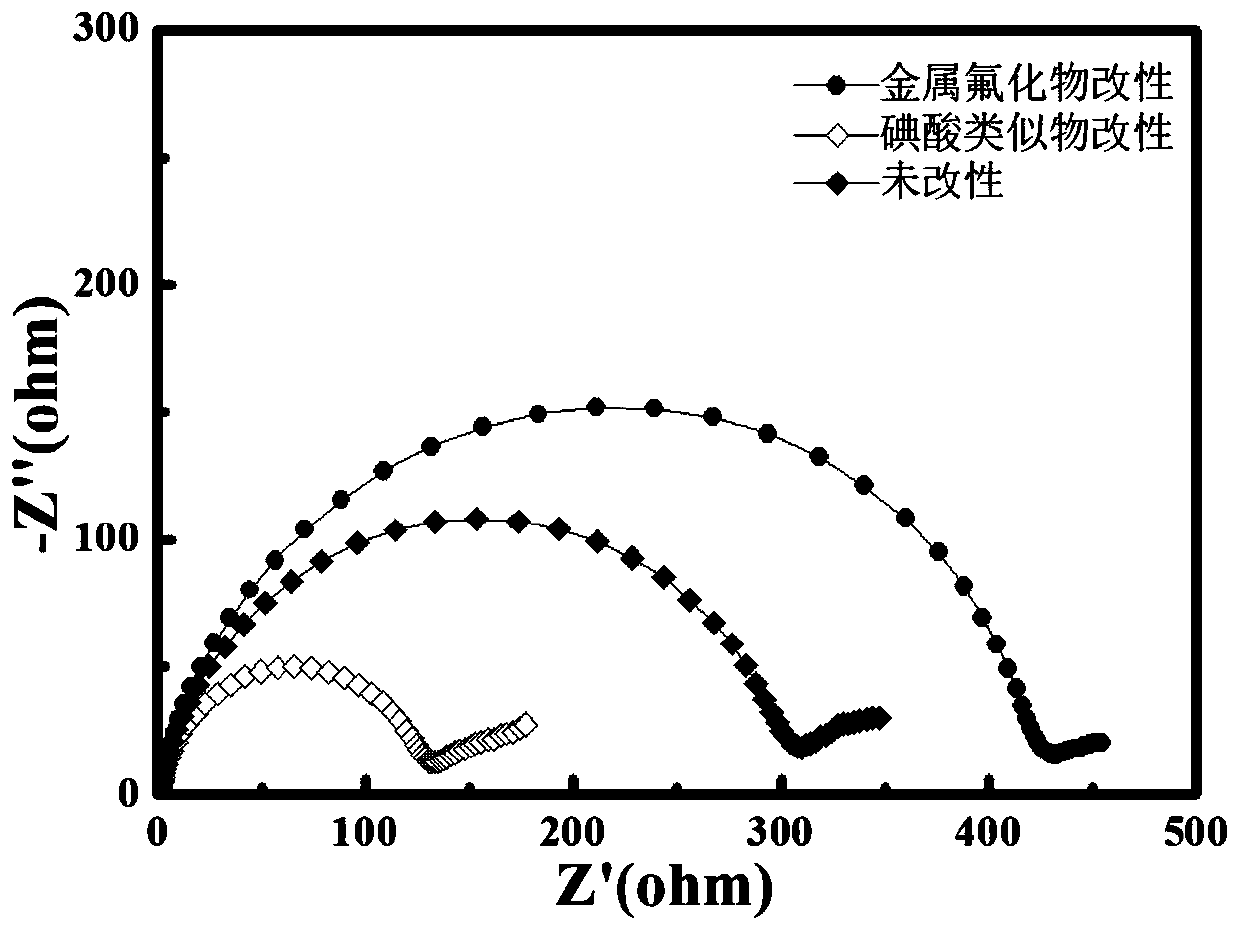

A technology of negative electrode material and metal lithium, applied in the field of metal lithium negative electrode material and its preparation, can solve the problems of poor electrode conductivity and dendrite growth, and achieve the effects of improving conductivity, preventing side reactions and stabilizing structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the metal lithium negative electrode material of the present embodiment comprises the following steps:

[0029] (1) After mixing the ground ferric fluoride and the binder polyvinylidene fluoride, coat it on the copper foil and dry it in a vacuum oven;

[0030] (2) Surface polishing is carried out on the metal lithium placed in the argon atmosphere until the metal lithium surface presents a metallic luster;

[0031] (3) bonding and compacting the polished lithium metal to the iron fluoride pole piece in step (1);

[0032] (4) heating the metal lithium bonded with the metal fluoride in (3) for 2 hours, and the heating temperature is 60° C.;

[0033] (5) The metal lithium and the iron fluoride pole pieces are separated, and the surface residues of the metal lithium are cleaned with ethylene carbonate to prepare the metal lithium negative electrode material.

[0034] A protective layer of lithium fluoride and metallic iron is formed on the surfac...

Embodiment 2

[0036] The preparation method of the metal lithium negative electrode material of the present embodiment comprises the following steps:

[0037] (1) After the aluminum fluoride after grinding is mixed with the binder polytetrafluoroethylene, it is coated on the copper foil and dried in a vacuum oven;

[0038] (2) polishing the surface of the lithium aluminum alloy placed in an argon atmosphere until the surface of the lithium aluminum alloy presents a metallic luster;

[0039] (3) bonding and compacting the polished lithium aluminum alloy to the aluminum fluoride pole piece in step (1);

[0040] (4) Heating the lithium aluminum alloy bonded with aluminum fluoride in (3) for 6 hours at a heating temperature of 80°C;

[0041] (5) The lithium aluminum alloy and the aluminum fluoride pole piece are separated, and the surface residue of the lithium aluminum alloy is cleaned with dimethyl carbonate to obtain a metal lithium negative electrode material.

[0042] A protective layer ...

Embodiment 3

[0044] The preparation method of the metal lithium negative electrode material of the present embodiment comprises the following steps:

[0045] (1) After the zinc fluoride after grinding is mixed with the binder polyacrylic acid, it is coated on the copper foil and dried in a vacuum oven;

[0046] (2) The lithium-zinc alloy placed in an argon atmosphere is surface-polished until the surface of the lithium-zinc alloy presents a metallic luster;

[0047] (3) Laminating and compacting the polished lithium-zinc alloy with the zinc fluoride pole piece in step (1);

[0048] (4) Heating the lithium-zinc alloy bonded with zinc fluoride in (3) for 12 hours at a heating temperature of 100°C;

[0049] (5) The lithium-zinc alloy and the zinc fluoride pole piece are separated, and the surface residue of the lithium-zinc alloy is cleaned with diethyl carbonate to obtain a metal lithium negative electrode material.

[0050] A protective layer of lithium fluoride and lithium-zinc alloy is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com