Ultra-light graphene foam material with effects of sound absorption and noise reduction and preparation method of ultra-light graphene foam material

A graphene foam and noise reduction technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of unsatisfactory medium and low frequency sound absorption coefficient, limited medium and low frequency sound absorption performance, and no corrosion resistance. Excellent sound absorption effect, simple method, excellent corrosion resistance and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

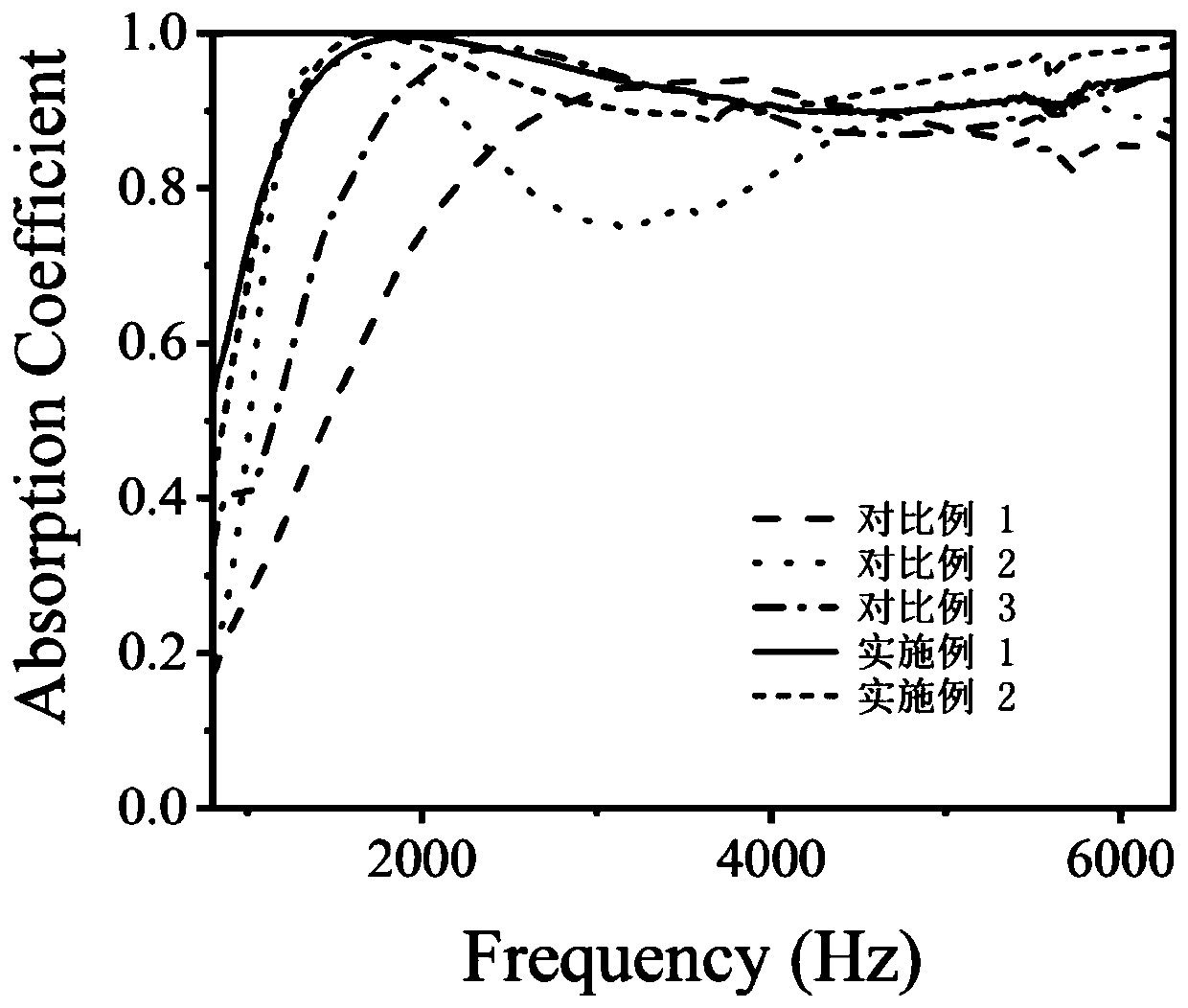

Embodiment 1

[0030] (1) prepare the graphene oxide solution that concentration is 7mg / mL;

[0031] (2) 50mL graphene oxide solution, 1mL Tween 80 and 6mL absolute ethanol were mixed, then mechanically stirred at a speed of 3000r / min for 5min, and the volume of the mixed solution was expanded to twice the volume before stirring to obtain graphite oxide Alkene wet foam;

[0032] (3) Place a 5mm thick plastic plate on the surface of liquid nitrogen, and then place the beaker with graphene oxide wet foam on the plastic plate to freeze, avoid direct contact between the beaker and liquid nitrogen, freeze for 20 minutes, and then transfer to freeze-dry Freeze-drying in the machine, freeze-drying at a vacuum degree of 10Pa and a temperature of -53°C for 60h to obtain a graphene oxide foam;

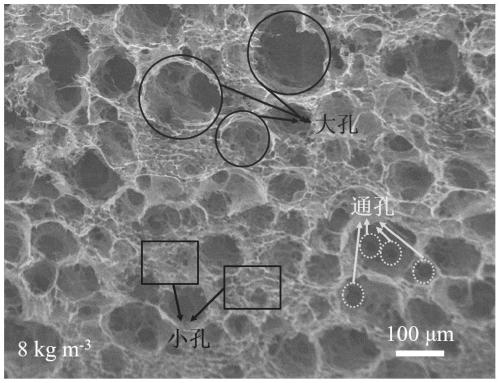

[0033] (4) Place the graphene oxide foam in a muffle furnace, heat it to 200°C in an air atmosphere, and keep it warm for 2 hours to obtain a sound-absorbing and noise-reducing ultra-light graphene foam mater...

Embodiment 2

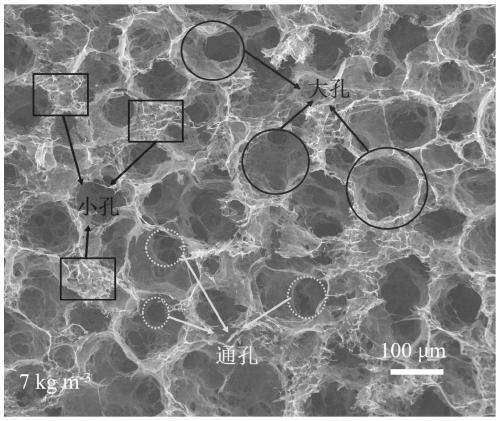

[0037] (1) prepare the graphene oxide solution that concentration is 5mg / mL;

[0038] (2) 50mL graphene oxide solution, 1mL Tween 80 and 6mL absolute ethanol were mixed, then mechanically stirred at a speed of 3000r / min for 5min, and the volume of the mixed solution was expanded to 2.5 times the volume before stirring to obtain graphite oxide Alkene wet foam;

[0039] (3) Place a 5mm thick plastic plate on the surface of liquid nitrogen, and then place the beaker with wet graphene oxide foam on the plastic plate to freeze, avoid direct contact between the beaker and liquid nitrogen, freeze for 30 minutes, and then transfer to freeze-dry Freeze-drying in the machine, freeze-drying at a vacuum degree of 10Pa and a temperature of -53°C for 60h to obtain a graphene oxide foam;

[0040] (4) Place the graphene oxide foam in a muffle furnace, heat it to 200°C in an air atmosphere, and keep it warm for 2 hours to obtain a sound-absorbing and noise-reducing ultra-light graphene foam m...

Embodiment 3

[0044] (1) prepare the graphene oxide solution that concentration is 5mg / mL;

[0045] (2) Mix 70mL graphene oxide solution, 1.5mL Tween 80, and 8mL absolute ethanol, and then mechanically stir rapidly at a speed of 3000r / min for 7min, so that the volume of the mixed solution expands to 2.5 times the volume before stirring to obtain the oxidized Graphene wet foam;

[0046] (3) Place a 5mm thick plastic plate on the surface of liquid nitrogen, and then place the beaker with wet graphene oxide foam on the plastic plate to freeze, avoid direct contact between the beaker and liquid nitrogen, freeze for 40 minutes, and then transfer to freeze-dry Freeze-drying in the machine, freeze-drying at a vacuum degree of 10Pa and a temperature of -53°C for 72h to obtain a graphene oxide foam;

[0047] (4) Place the graphene oxide foam in a muffle furnace, heat it to 200°C in an air atmosphere, and keep it warm for 2 hours to obtain a sound-absorbing and noise-reducing ultra-light graphene fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com