Titanium carbide nanosheet/layered indium sulfide heterojunction and application of the same in degrading and removing water pollutant

A nanosheet, titanium carbide technology, applied in water pollutants, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of reduced photocatalytic activity, low photon quantum yield, and fast photogenerated carrier recombination rate, etc. To achieve the effect of uniform growth, good repeatability and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ti 3 C 2 The preparation of two-dimensional transition metal carbide nanosheets, the specific steps are as follows:

[0034] Add 0.8 g LiF to 10 ml 9 mol / L hydrochloric acid and stir for about 5 minutes, then add 0.4 g Ti within 5 minutes 3 AlC 2 , to prevent bumping. Then stirred at 25 °C for 24 h for etching, the reaction product was centrifuged and washed with water until the pH reached about 6, then deionized water was added, the layers were separated by hand shaking for 15 minutes, and centrifuged again to obtain the two-dimensional transition metal carbide Ti 3 C 2 The nanosheets are a black colloidal solution, stored in a refrigerator at 4 °C, and recorded as solution A.

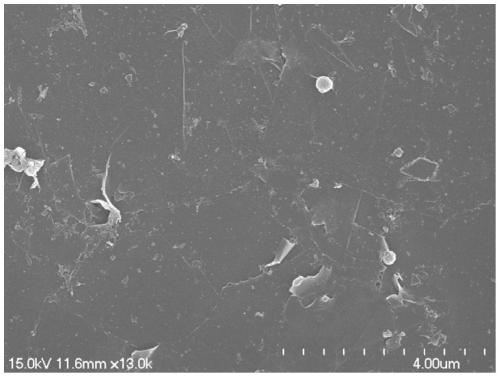

[0035] attached figure 1 Ti obtained above 3 C 2 SEM image of Ti 3 C 2 MXene is a two-dimensional layered material, the thickness of nanosheets is on the order of nanometers, the plane size is on the order of micrometers, the surface defects are less, and the specific surface area is ...

Embodiment 2

[0037] Indium salt and Ti 3 C 2 The electrostatic self-assembly of nanosheets, the specific steps are as follows:

[0038] 0.8 mmol InCl 3 4H 2 O and 10 mL of deionized water were added to a 50 mL one-necked flask and stirred for 1 hour, which was recorded as solution B, and then 10 mL of solution A obtained in Example 1 was added (the quality of the two-dimensional transition metal carbide nanosheets was 1 / 2 of the mass of indium sulfide. 2%) and then stirred for 1.5 h. Indium ions adsorb on the negatively charged Ti on its surface 3 C 2 On the surface of the nanosheets, the stabilized Ti 3 C 2 The colloidal solution coagulates.

Embodiment 3

[0040] After the air was replaced with argon protective gas, the reflux reaction was carried out. The specific steps are as follows:

[0041] Add 1.2 mmol thioacetamide to the flask in Example 2. The molar ratio of indium and sulfur in the system is 2:3. After stirring for ten minutes, connect a spherical condenser and a three-way valve, and seal the interface well. First use a vacuum pump to remove the air in the flask and condenser, and then use an air bag to blow in argon. Put the above device into the oil bath, add condensed water and reflux at 95°C for 1.5h, and put it into the ice-water mixture to cool down quickly after the reflux. The cooled reaction product was centrifuged three times with a mixed solvent of water and ethanol, then centrifuged once with ethanol, and then dried in a vacuum oven to constant weight to obtain a titanium carbide nanosheet / layered indium sulfide heterojunction.

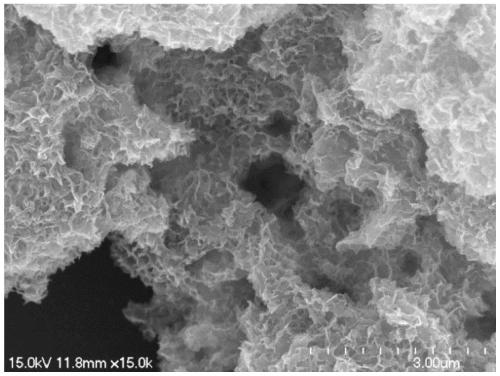

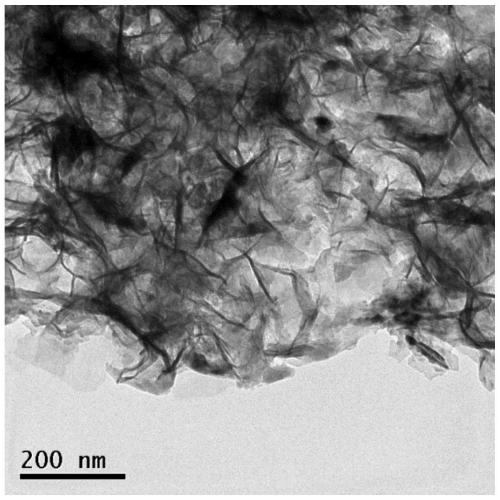

[0042] attached figure 2 It is the scanning electron microscope picture of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com