Preparation method of fiber toughened porous silicon nitride ceramics

A technology for toughening silicon nitride ceramics and fibers, which is applied in ceramic products, applications, household appliances, etc., can solve the undisclosed problems of strengthening porous silicon nitride ceramics, and achieve high toughness, high porosity, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing fiber-toughened porous silicon nitride ceramics of the present invention comprises the following steps:

[0032] S1, melamine is dissolved in formaldehyde and the first deionized water, by volume ratio, melamine: formaldehyde: the first deionized water=1: (2.5~3.5): (50~55), the water bath is heated to 60~ 75°C, and continue the reaction for 15-25 minutes to obtain a white transparent liquid of methylol melamine;

[0033] S2, dissolving ethyl orthosilicate in absolute ethanol and the second part of deionized water, ethyl orthosilicate: absolute ethanol: the quality of the second part of deionized water is 100: (25~30): (12 ~15), heated to 40~65°C under constant stirring, and continued to react for 20~30min to obtain a transparent solution.

[0034] S3. Mix the white transparent liquid obtained in step S1 with the transparent solution obtained in step S2, the volume ratio of white transparent liquid: transparent solution (1-2): 1, then heat to 60-...

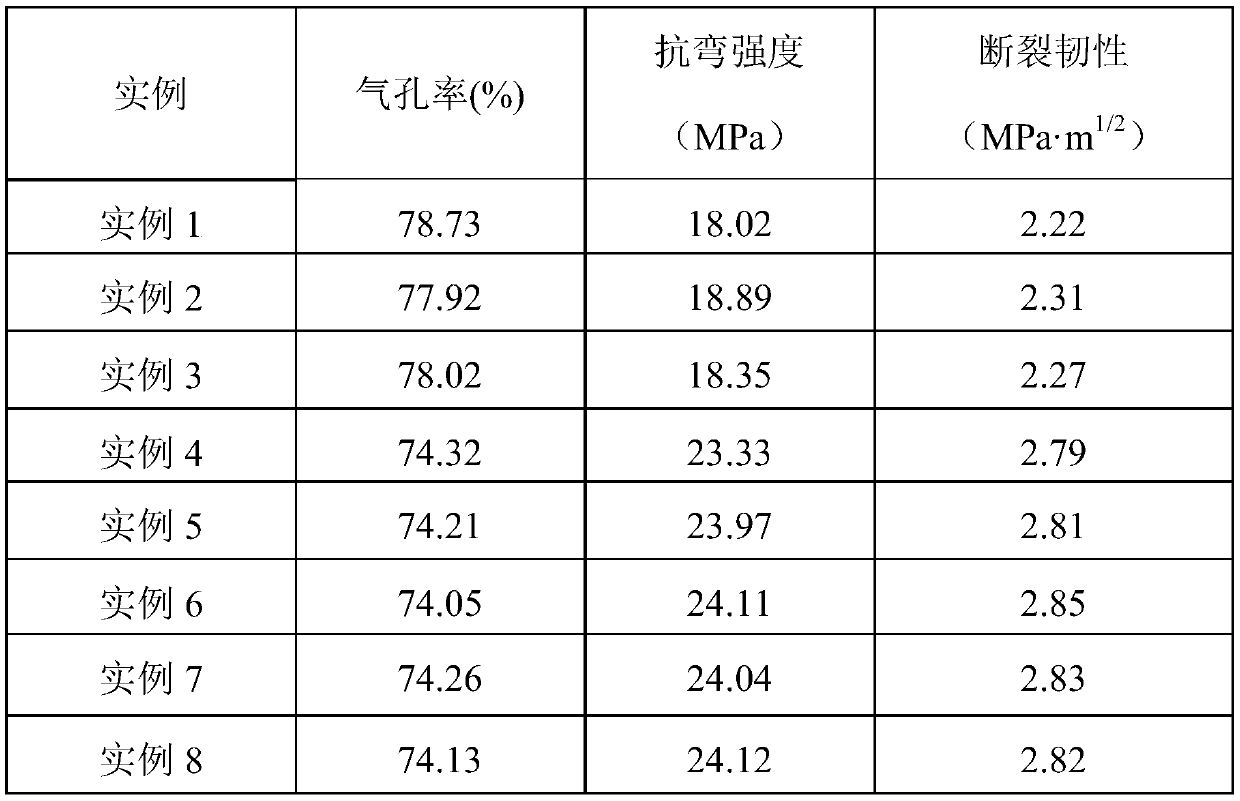

Embodiment 1

[0042] (1) Heat the solution of melamine, formaldehyde and water with a volume ratio of 1:2.5:50 to 60°C in a water bath, and continue the reaction for 15 minutes to obtain a white transparent liquid of methylolmelamine;

[0043] (2) Heat a solution of tetraethyl orthosilicate, absolute ethanol, and deionized water at a mass ratio of 100:25:12 to 40° C. under constant stirring, and continue to react for 25 minutes to obtain a transparent solution.

[0044] (3) Mix the white transparent liquid of methylolmelamine obtained in step (1) and the transparent solution obtained in step (2) at a ratio of 1:1, then heat to 60°C, add nitric acid into the mixed transparent solution and keep stirring , adjust the pH value to 4 to form a gel;

[0045] (4) Dry the colloid obtained in step 3 in an oven at 70° C. for 24 hours to obtain xerogel powder.

[0046] (5) Mix and grind the dry gel powder prepared in step 4 and the carbon quantum dots according to the molar ratio of 1:2, and pass throug...

Embodiment 2

[0049] (1) Heat the solution of melamine, formaldehyde and water with a volume ratio of 1:3.5:55 to 65°C in a water bath, and continue the reaction for 15 minutes to obtain a white transparent liquid of methylolmelamine;

[0050] (2) Heat a solution of tetraethyl orthosilicate, absolute ethanol and deionized water at a mass ratio of 100:30:15 to 60° C. under constant stirring, and continue to react for 20 minutes to obtain a transparent solution.

[0051] (3) Mix the white transparent liquid of methylol melamine obtained in step (1) with the transparent solution obtained in step (2) at a ratio of 2:1, then heat to 75°C, add nitric acid into the mixed transparent solution and stir continuously, Adjust the pH value to 1 to form a gel;

[0052] (4) Dry the colloid obtained in step 3 in an oven at 80° C. for 18 hours to obtain xerogel powder.

[0053] (5) Mix and grind the dry gel powder prepared in step 4 and carbon quantum dots according to the molar ratio of 1:2.2, and pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com