Porous biological ceramic coating with antibiosis and bone promoting functions as well as preparation method and application thereof

A bioceramic and bone-promoting technology, which is applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of anti-infection performance of few implants, achieve the purpose of inhibiting bacterial adhesion and growth, not easy to peel off, and promoting The effect of osteocyte osteogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

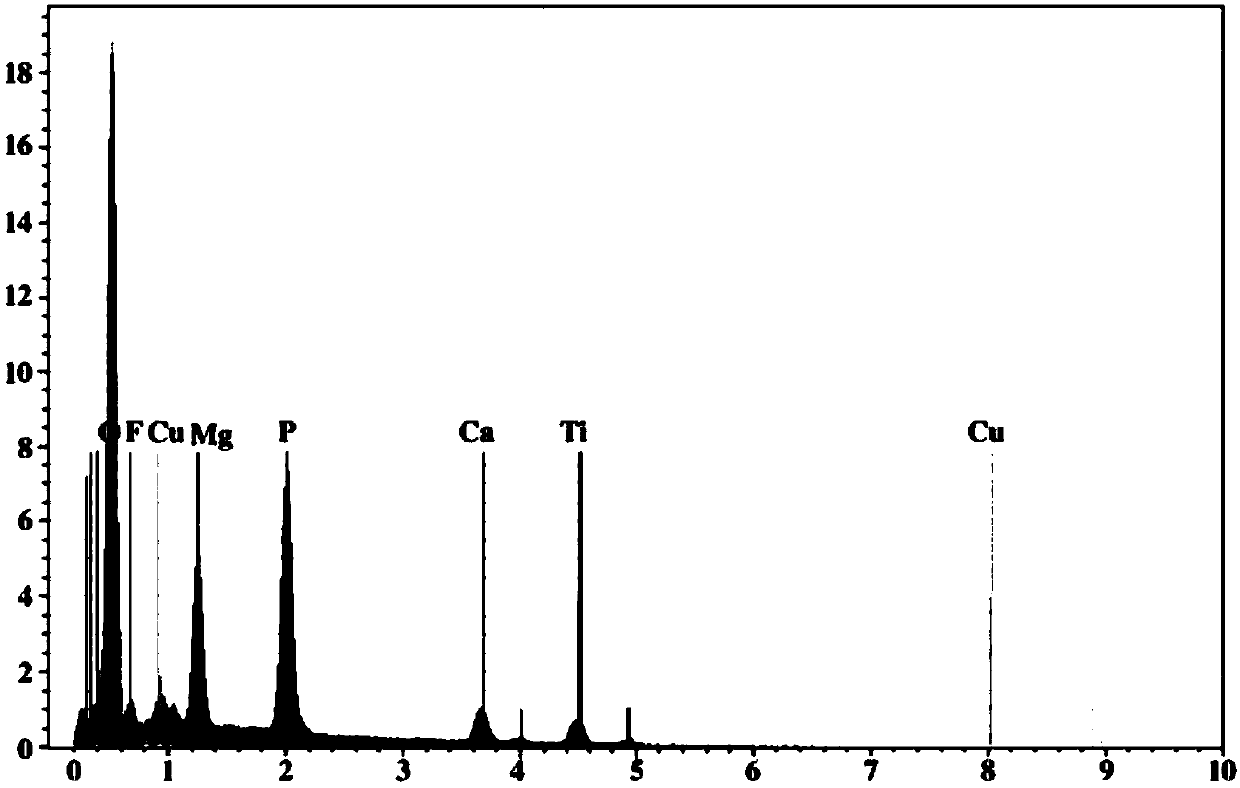

[0032]The preparation method of the porous bioceramic coating with both antibacterial and bone-promoting properties provided by the present invention comprises the following steps: dissolving copper source, magnesium source, fluorine source, calcium source and phosphorus source in deionized water to prepare electrolyte, to The medical titanium alloy sample is the anode, the stainless steel is the cathode, the pulse voltage is 100-500V, the frequency is 100-600Hz, the duty cycle is 10-80%, and the distance between the cathode and anode plates is 60-180mm. The sample is subjected to micro-arc oxidation treatment, the temperature of the electrolyte is kept below 30°C, and the treatment time is 5-30 minutes. After the reaction is completed, porous organisms doped with copper, magnesium, fluorine, calcium and phosphorus elements are formed on the surface of the titanium alloy. The active coating, that is, the porous bioceramic coating of the present invention that has both antibacte...

Embodiment 1

[0036] 1) Pretreatment.

[0037] Grind and polish the medical titanium alloy with 100#, 300#, 600#, 1500#, and 3000# sandpaper in sequence, and then use anhydrous acetone, anhydrous ethanol, and deionized water to ultrasonicate for 30 minutes each.

[0038] 2) Electrolyte preparation.

[0039] Dissolve calcium gluconate, magnesium gluconate, copper gluconate, sodium fluoride, sodium hexametaphosphate, and sodium hydroxide in deionized water, mix well, and prepare an electrolyte; the concentration of copper gluconate ions in the electrolyte is 0.005 mol / L, the concentration of magnesium gluconate ion is 0.01mol / L, the concentration of sodium fluoride ion is 0.01mol / L, the concentration of calcium gluconate ion is 0.01mol / L, the concentration of sodium hexametaphosphate is 0.01mol / L L, the concentration of sodium hydroxide is 0.005.

[0040] 3) Micro-arc oxidation.

[0041] With medical titanium alloy as the anode and stainless steel as the cathode, the unidirectional flow pu...

Embodiment 2

[0049] 1) Pretreatment.

[0050] Grind and polish the medical titanium alloy with 100#, 300#, 600#, 1500#, and 3000# sandpaper in sequence, and then use anhydrous acetone, anhydrous ethanol, and deionized water to ultrasonicate for 30 minutes each.

[0051] 2) Electrolyte preparation.

[0052] Dissolve calcium gluconate, magnesium gluconate, copper gluconate, sodium fluoride, sodium hexametaphosphate, and sodium hydroxide in deionized water, mix well, and prepare an electrolyte; the concentration of copper gluconate ions in the electrolyte is 0.005 mol / L, the concentration of magnesium gluconate ion is 0.01mol / L, the concentration of sodium fluoride ion is 0.02mol / L, the concentration of calcium gluconate ion is 0.01mol / L, the concentration of sodium hexametaphosphate is 0.005mol / L L, the concentration of sodium hydroxide is 0.005.

[0053] 3) Micro-arc oxidation.

[0054] With medical titanium alloy as the anode and stainless steel as the cathode, a unidirectional flow pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com