Preparation method of hollow metal oxide nano material

A technology of nanomaterials and oxides, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of complex process and many influencing factors, and achieve the effect of simple synthesis, less control parameters and economical savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

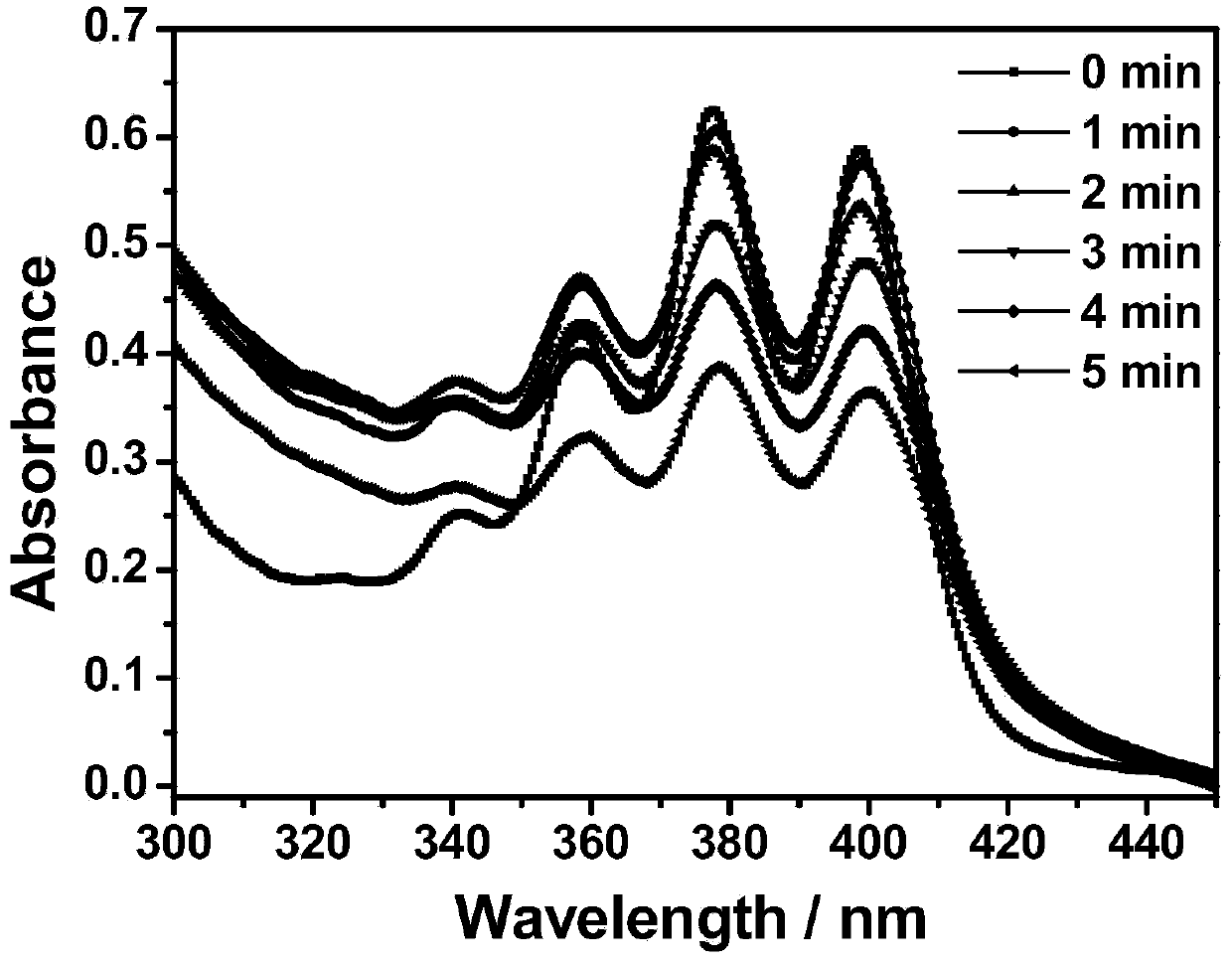

Image

Examples

preparation example Construction

[0040] Preparation of 250 nm ZIF-8 nanoparticles

[0041] Weigh 16mmol of zinc nitrate hexahydrate and 64mmol of 2-methylimidazole and dissolve them in 100mL of methanol solvent to form a uniform dispersion solution, mix well and continue to react for 2 hours at a stirring speed of 400r / min to obtain the final 250nm size The nanoparticle product was centrifuged, washed, and vacuum-dried at 40°C.

[0042] Preparation of 140 nm ZIF-8 nanoparticles

[0043] Weigh 16mmol of zinc nitrate hexahydrate and 64mmol of 2-methylimidazole and dissolve them in 100mL of methanol solvent to form a uniform dispersion solution, mix well and continue to react for 2 hours at a stirring speed of 400r / min to obtain the final 140nm size The nanoparticle product was centrifuged, washed, and vacuum-dried at 40°C.

[0044] Preparation of 50 nm ZIF-8 nanoparticles

[0045] Weigh 16mmol of zinc nitrate hexahydrate and 64mmol of 2-methylimidazole and dissolve them in 500mL of methanol solvent to form a...

Embodiment 1

[0051] Take by weighing 25mg prepared 250nm ZIF-8 nanoparticles and disperse them in the ethanol-ethylene glycol mixed treatment solution of 15mL 5:1 (volume ratio, the same below), to form ZIF-8 sol dispersion system A; Weigh 0.2mmol Manganese chloride dihydrate, 3mmol ammonium chloride and 20mmol ammonia water (mass percentage concentration 28%, the same below) were mixed and dispersed in 15mL (volume ratio: 9:1, the same below) of ethanol-water mixed treatment solution to form B solution ; At room temperature, the two solutions of A and B were quickly mixed, stirred and reacted at 330r / min for 16 hours, centrifuged, washed alternately with water and ethanol, and vacuum-dried at 40°C to finally obtain the final hollow manganese oxide nanoparticles. The TEM images of the samples are shown in figure 1 .

Embodiment 2

[0053] Weigh 25mg of prepared 50nm ZIF-8 nanoparticles and disperse them into 15mL of 5:1 ethanol-ethylene glycol mixed treatment solution to form ZIF-8 sol dispersion system A; weigh 0.4mmol manganese chloride dihydrate, 6mmol Ammonium chloride and 40mmol ammonia water (28%) were mixed and dispersed in 15mL 9:1 ethanol-water mixed treatment solution to form B solution; at room temperature, the two solutions A and B were quickly mixed and stirred at 330r / min for reaction After 16 hours, centrifugation, alternate washing with water and ethanol, and vacuum drying at 40°C, the final hollow manganese oxide nanoparticles were finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com