Water-soluble hyperbranched polymer thick oil viscosity reducing agent and preparation method thereof

A hyperbranched polymer, water-soluble technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of complicated synthesis or compounding steps, small reservoir condition range, poor temperature and salt resistance, etc. , to achieve the effect of low cost, simple synthesis steps, strong temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

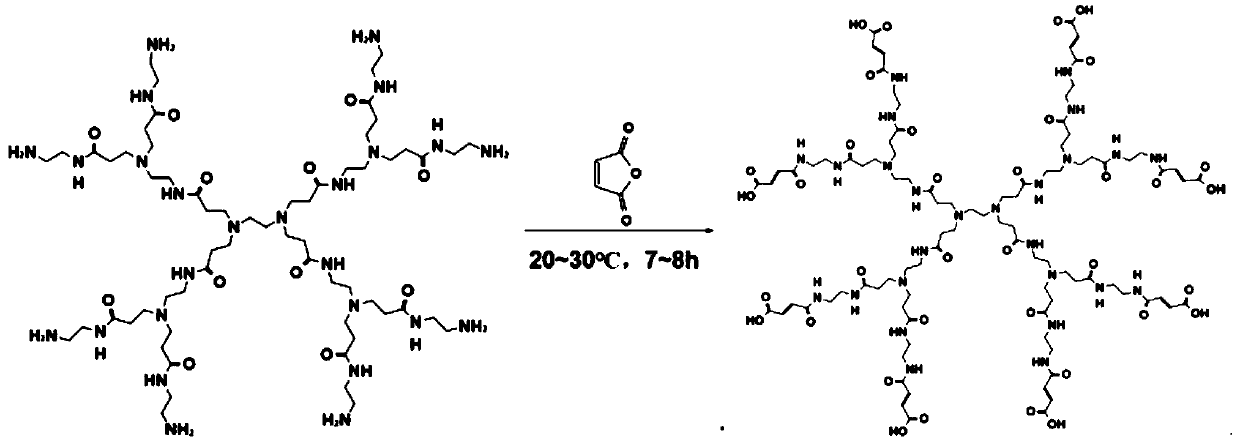

[0051] (a) Functional modification of backbone monomers

[0052] The 2.0 generation or 3.0 generation backbone monomer and maleic anhydride are sequentially dissolved in 2 to 3 times the mass ratio of N,N-dimethylformamide solvent in a molar ratio of 1:8 or 1:16; Place the system in an ice-water bath (below 10°C), and pass nitrogen gas for 40 minutes at the same time, and dissolve completely under stirring conditions; react for 6h to 7h at room temperature and avoid light; Precipitate milky white, light yellow powdery substance, which is relatively pure functionalized skeleton monomer.

[0053] Taking the modified 2.0 generation as an example, the preparation flow chart of the functionalized 2.0 skeleton monomer is as follows figure 1 shown.

[0054] Modified 2.0 generation polyamide-amine, its molecular structural formula is as shown in (1):

[0055]

[0056] Modified 3.0 generation polyamide-amine, its molecular structural formula is as shown in (2):

[0057]

[00...

Embodiment 2

[0068] The synthesis of water-soluble hyperbranched heavy oil viscosity reducer, its preferred scheme is as follows:

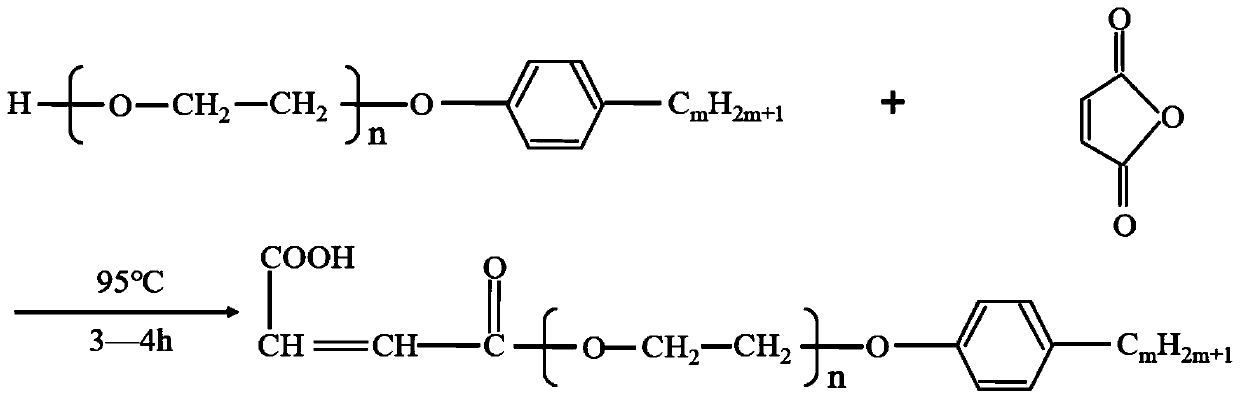

[0069] First, put a certain amount of deionized water in the reaction vessel, and mix 0.4% of functionalized backbone monomer 2.0 generation polyamidoamine, 14.5% of acrylamide, and 40.1% of modified The octylphenol polyoxyethylene ether maleic acid monoester (shown in formula 3, wherein n is 10, m is 8) and 45% sodium olefin sulfonate monomer (n 2 =14~16, Chengdu Kelong Chemical Reagent Factory, AOS liquid) mix and stir evenly, be mixed with the solution (mass fraction meter) that monomer concentration is 25%;

[0070] Secondly, by adding sodium hydroxide to adjust the pH value of the solution to 6.5, then under 45°C water bath heating and a stirring speed of 250r / min, the inert gas nitrogen was used for protection for 40min; then ammonium persulfate solution was slowly added dropwise, the over Ammonium persulfate in the ammonium sulfate solution is 0.01% re...

Embodiment 3

[0072] The synthesis of water-soluble hyperbranched heavy oil viscosity reducer, its preferred scheme is as follows:

[0073] First, put a certain amount of deionized water into the reaction vessel, and mix 0.1% of functionalized backbone monomer 3.0 generation polyamidoamine, 13.8% of acrylamide, 38.5% of modified Nonylphenol polyoxyethylene ether maleic acid monoester (shown in formula 3, n is 10, m is 9) and 47.6% sodium olefin sulfonate monomer, mixed and stirred evenly, and prepared into a monomer concentration of 25%. Solution (mass fraction meter);

[0074] Secondly, the pH value of the solution was adjusted to 6.7 by adding sodium carbonate, and then under 45°C water bath heating and a stirring rate of 250r / min, the inert gas nitrogen was passed for protection for 40min; then the ammonium persulfate solution was slowly added dropwise, and the persulfate Ammonium persulfate in the ammonium solution is 0.018% relative to the total mass of the monomers. After continuing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com