Preparation method of monodisperse anatase nano-titanium dioxide transparent liquid phase dispersion

A nano-titanium dioxide, anatase technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the excellent characteristics of nano-titanium dioxide cannot be exerted, the organic phase and the water phase can not be dispersed, and the Excellent characteristics and other issues, to achieve the effect of shortening the production cycle, strong experimental repeatability, and easy to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing a monodisperse anatase nano-titanium dioxide transparent liquid phase dispersion of the present invention comprises the following steps:

[0052] S1. Dissolve the titanium salt precursor in alcohol solvent, add acid after stirring at room temperature for 20-40 minutes, and record it as material solution A; mix alcohol solvent and deionized water at room temperature, record it as material solution B;

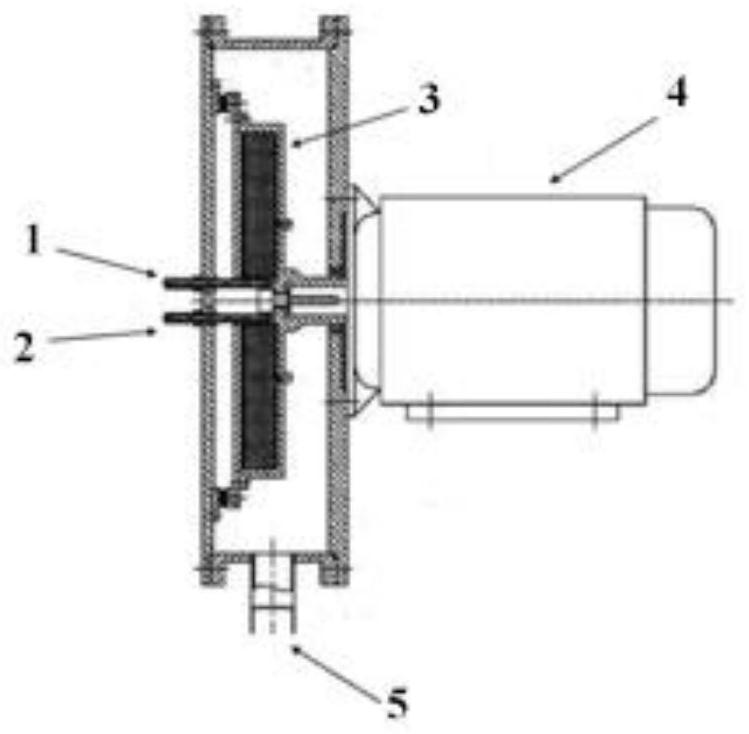

[0053] S2. Prepare a supergravity rotating packed bed reactor, and keep the temperature of the reactor at 5-50°C;

[0054] S3. Add feed liquids A and B to the high-gravity rotating bed reactor at the same time for reaction, and obtain a reaction solution after the reaction;

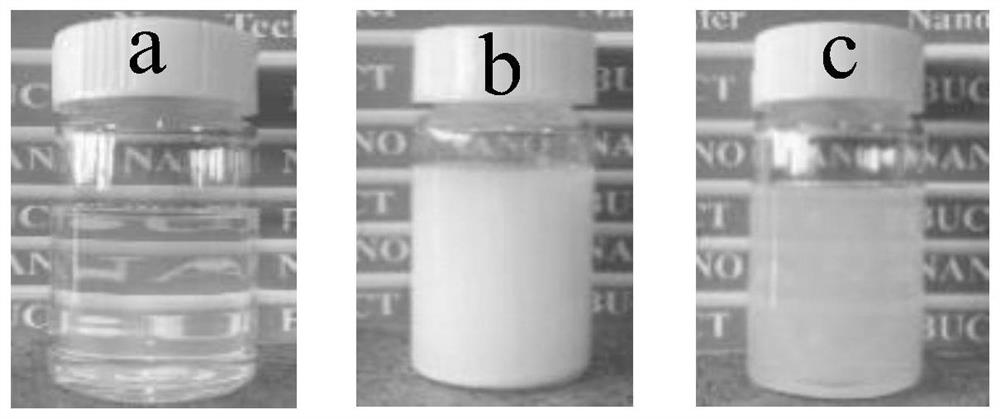

[0055] S4. Transfer the reaction solution to a high-temperature and high-pressure reactor for solvothermal or hydrothermal reaction to obtain a white precipitate of titanium dioxide;

[0056] S5, centrifuging, washing, modifying and dispersing the titanium dioxide white precipi...

Embodiment 1

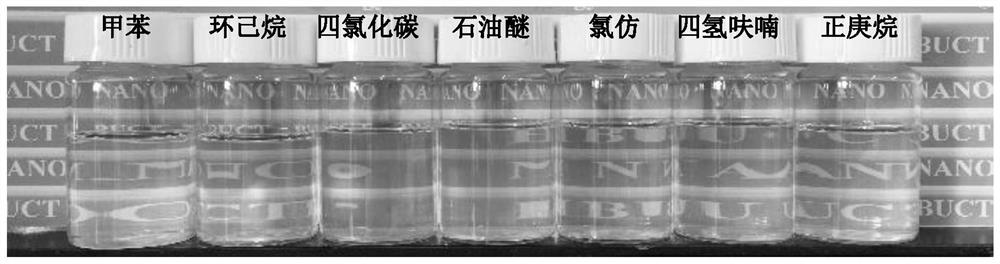

[0074] A method for preparing a monodisperse anatase nano-titanium dioxide transparent organic phase dispersion, comprising the steps of:

[0075] 1) Preparation of material solution A: Mix 80ml of ethanol, 40mL of butyl titanate, and 4ml of acetic acid and then magnetically stir for 30min; Preparation of material solution B: Mix 40ml of ethanol and 8ml of deionized water;

[0076] 2) use figure 1 For the device shown, first turn on the circulating water device, set the water temperature to 30°C, and heat the rotating packed bed reactor;

[0077] 3) Set the rotor speed to 2000rpm, turn on the rotary packed bed reactor, feed the feed liquids A and B into the rotary packed bed reactor through the peristaltic pump respectively, the flow rate of the feed liquid A is 180ml / min, and the flow rate of the feed liquid A Be 60ml / min, obtain titanium dioxide homogeneous sol;

[0078] 4) Solvothermally react the titanium dioxide homogeneous sol at 150° C. for 15 hours to obtain a white ...

Embodiment 2

[0105] A method for preparing a monodisperse anatase nano-titanium dioxide transparent tetrahydrofuran phase dispersion, comprising the steps of:

[0106] 1) Preparation of material solution A: Mix 80ml of n-decyl alcohol, 40mL of butyl titanate, and 4ml of acetic acid and then magnetically stir for 30min; preparation of material solution B: Mix 40ml of n-decyl alcohol and 8ml of deionized water;

[0107] 2) use figure 1 For the device shown, first turn on the circulating water device, set the water temperature to 30°C, and heat the rotating packed bed reactor;

[0108] 3) Set the rotor speed to 2000rpm, turn on the rotary packed bed, feed A and B feed liquids into the rotary bed reactor through peristaltic pumps respectively, the flow rate of feed liquid A is 180ml / min, and the flow rate of feed liquid A is 60ml / min min, obtain titanium dioxide homogeneous sol;

[0109] 4) Solvothermally reacting the sol at 150°C for 15 hours to obtain a white precipitate of titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com