Recombinant penicillium chrysogenum gene engineering strain and construction method and application thereof

A technology of genetically engineered bacteria and Penicillium chrysogenum, applied in genetic engineering, microbial-based methods, applications, etc., can solve the problems of high kinetic energy consumption, high cost, and long cultivation time, and achieve good adsorption and combination and increase potency , the effect of shortening 24h

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

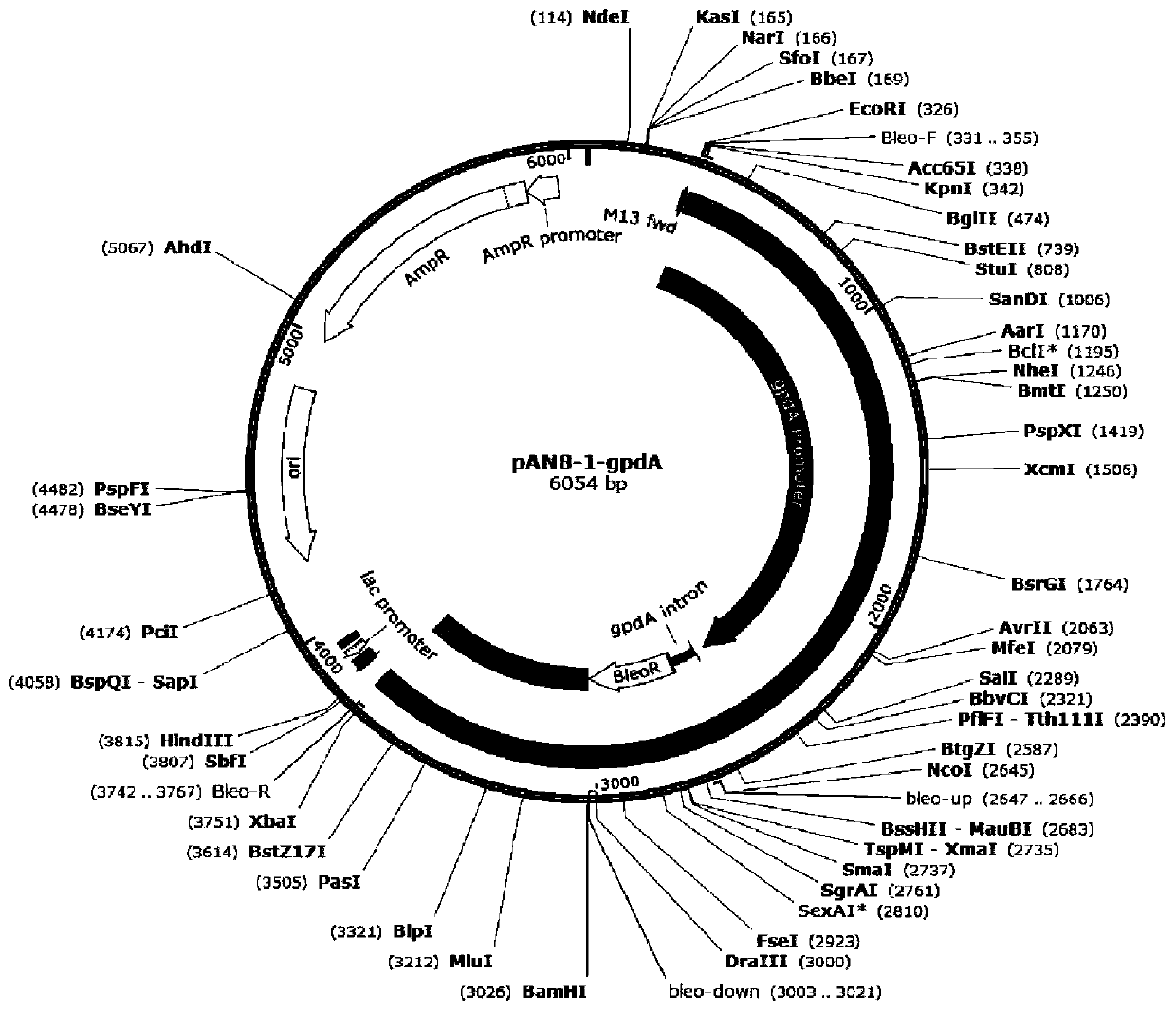

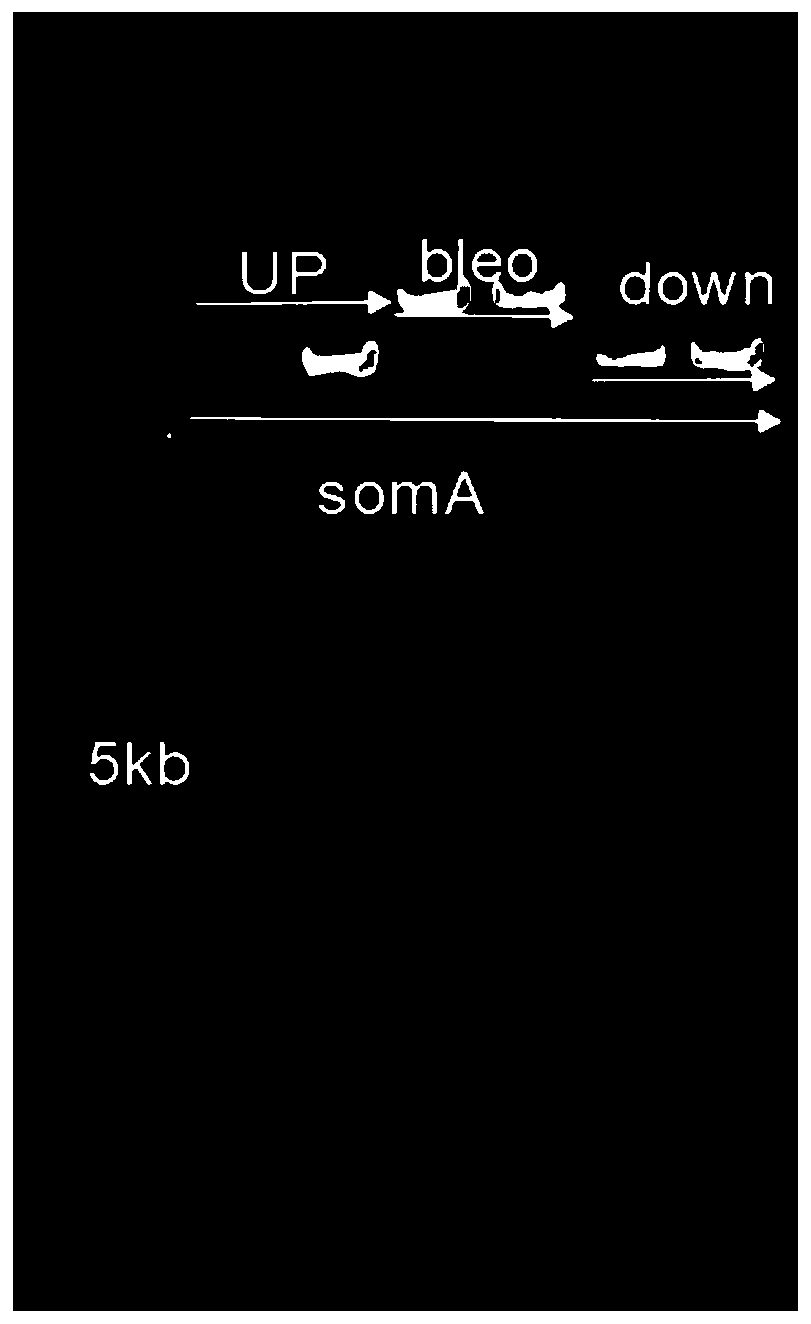

[0057] Example 1: Construction of Penicillium chrysogenum Pc-somA gene knockout bacteria.

[0058] (1) Extraction of the original Penicillium chrysogenum genome

[0059] Use the kit (FastPure plant DNA IsolationMini kit) that Vazyme company extracts plant genome, specific method is as follows:

[0060] The activation of bacteria is as follows: Gently scrape the Penicillium chrysogenum engineering bacteria activated on the IPM plate with the buffer solution of scraping spores to make spore liquid (hemocytometer plate counts 10 8 / mL).

[0061] 1. Inoculate 400uL of scraped Penicillium chrysogenum spore liquid into 100mL LYPD medium, and incubate at 25°C, 220r / min for 10.5h;

[0062] 2. Use a filter cloth to filter and collect mycelium balls, centrifuge at 5000r / min for 5min, wash twice with PBS, grind the collected mycelium balls with liquid nitrogen for at least 3 times, weigh 0.1g of ground powder and add to 1.5mL in a centrifuge tube. Immediately add 400uL of Buffer A1 a...

Embodiment 2

[0091] Embodiment 2: crystal violet dyeing experiment

[0092] Inoculate the original Penicillium chrysogenum and the genetically engineered bacteria on the IPM plate respectively, and when the spores are overgrown, add 2 mL of spore scraping buffer to the plate, scrape off the spores with a coating stick, then wash with 1 mL of spore scraping liquid and transfer to the sterilized plate. Bacteria in a 5mL centrifuge tube, dilute to 2mL with spore scraping buffer to obtain spore liquid. Quantify with a hemocytometer and dilute to 10 6 cells / mL, then continue to dilute to 10 6 、10 5 、10 4 、10 3 、10 2 .

[0093] Add 1 mL of synthetic medium in advance to the 24-well plate, and then inoculate 4 uL of different concentrations of spore liquid into the medium. Cultivate statically at 35°C for 72 hours to make Penicillium chrysogenum form a film on the bottom of the well plate; then pour out the medium, wash it twice with PBS, add 0.1% crystal violet to stain for 15 minutes; th...

Embodiment 3

[0097] Embodiment 3: Immobilized fermentation experiment of genetically engineered bacteria.

[0098] 1. Preparation of plastic medium as immobilization medium

[0099] (1) Wash the plastic medium-polymethyl methacrylate in deionized water for about 4 minutes, then extract the cleaned plastic medium in acetone for 24 hours to remove surface oil and impurities, and bake in an oven at 45°C for 30 minutes.

[0100] (2) Place the treated plastic medium in (1) on a SDCD16-3-20 type corona treatment equipment for corona treatment with a current intensity of 8A for 15 minutes, and store it in a refrigerator at 4°C for standby.

[0101] 2. Configuration of fermentation medium

[0102] Components of immobilized fermentation medium: soybean cake powder 4.65%, calcium carbonate 1%, lactose 3%, potassium dihydrogen phosphate 0.5%, ammonium sulfate 0.4%, sodium sulfate 0.15%, salad oil 0.03%, phenylacetic acid 2.5%, The solvent is water, pH=5.8.

[0103] 3. The fermentation steps are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com