811NCM ternary cathode material of three-dimensional nanowire array structure and preparation method thereof

A three-dimensional nano, cathode material technology, applied in the field of electrochemical applications, can solve the problems of particle breakage, incomplete precipitation, particle agglomeration, etc., achieve uniform size, good shape, and improve the effect of particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

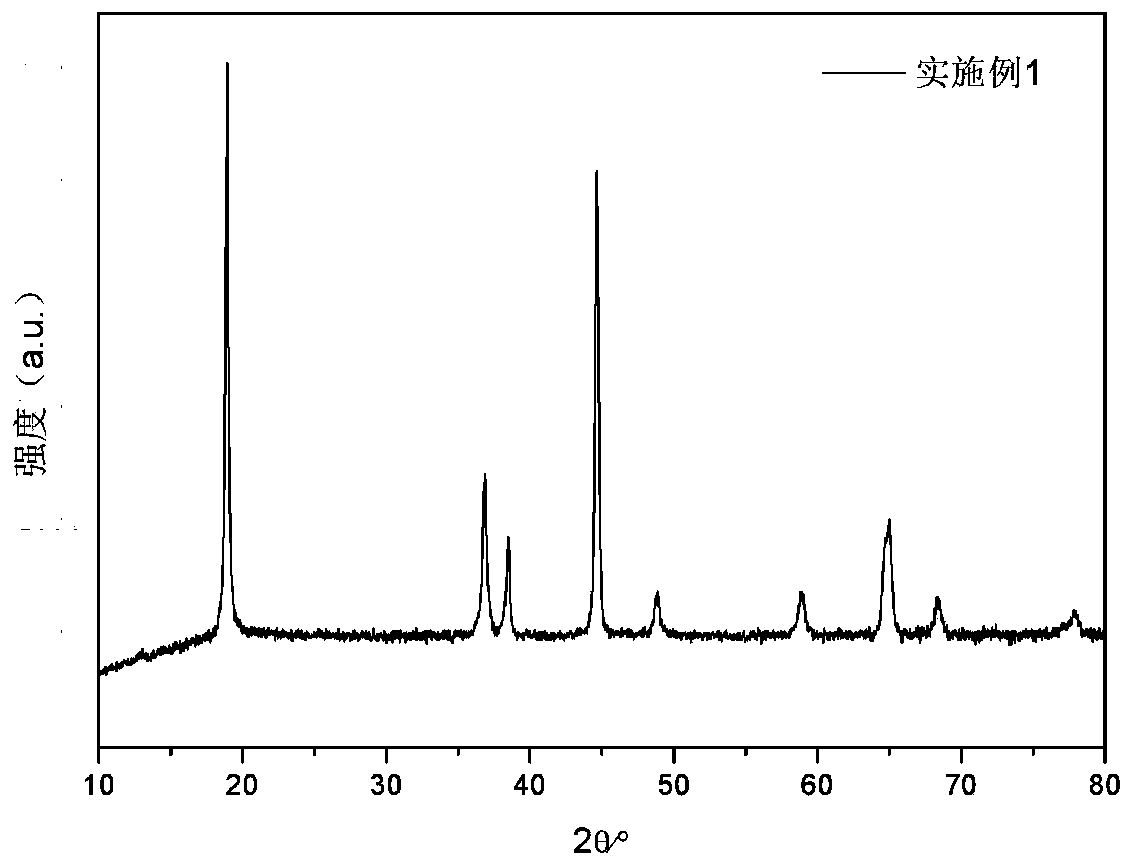

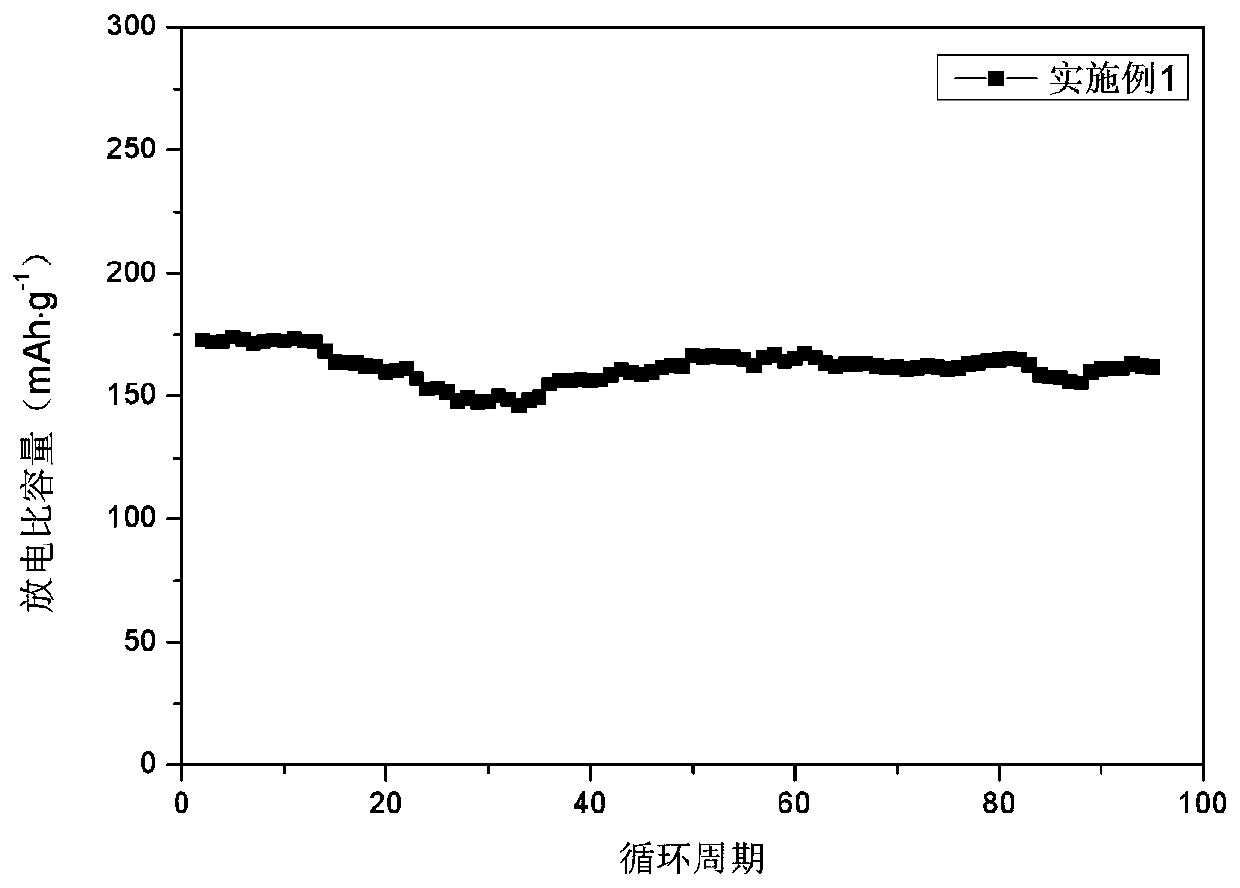

[0024] The 811NCM ternary cathode material in this example has a layered crystal structure, and its microscopic appearance is as follows: after the self-assembly of primary spherical single crystal particles into nanowires, these nanowires self-assemble into a strip-like array structure Morphology, the particle size is basically between about 10 μm in length and about 2 μm in width.

[0025] The preparation method of the present embodiment, the steps are as follows:

[0026] Step (1), dissolving 0.08mol of nickel acetate, 0.01mol of manganese acetate and 0.01mol of cobalt acetate in 100mL of deionized water, stirring evenly until completely dissolved; then adding 0.2mol of oxalic acid powder, stirring evenly until the oxalic acid is completely dissolved, Obtain the mixed solution, the measured pH value is 5, then add the concentration of 0.01mol L -1 The ammonia solution adjusts pH=7;

[0027] Step (2): Take 80mL of the mixed solution prepared in step (1) and pour it into a ...

Embodiment 2

[0036] The 811NCM ternary positive electrode material in this embodiment has a layered crystal structure, and its microscopic appearance is as follows: after the self-assembly of spherical single crystal particles into nanowires, these nanowires self-assemble into The shape of the strip-shaped array structure, the particle size is basically between about 50 μm in length and about 3 μm in width.

[0037] The preparation method of the present embodiment, the steps are as follows:

[0038] Step (1), dissolve 0.04mol of nickel chloride and 0.04mol of nickel acetate in 20mL of ethylene glycol solution and stir until completely dissolved to obtain solution A; dissolve 0.005mol of cobalt chloride and 0.005mol of cobalt acetate Stir in 20mL of ethylene glycol solution until completely dissolved to obtain solution B; dissolve 0.005mol of manganese chloride and 0.005mol of manganese acetate in 20mL of ethylene glycol solution and stir until completely dissolved to obtain solution C; So...

Embodiment 3

[0048] An 811NCM ternary positive electrode material with a three-dimensional nanowire array structure, the crystal structure is a layered structure, and the microscopic appearance is: after the self-assembly of spherical single crystal particles into nanowires, these nanowires self-assemble into long Striped array structure morphology, the particle size is basically between 10 μm in length and 1 μm in width.

[0049] A preparation method of 811NCM ternary cathode material with a three-dimensional nanowire array structure, the steps are as follows:

[0050] Step (1), dissolve 0.004 mol of nickel acetate and 0.004 mol of nickel sulfate in a mixed solution of 20 mL of deionized water and glycerin (the ratio of deionized water to glycerin is 2:1), stir well until completely dissolved to obtain solution A; dissolve 0.004mol of cobalt acetate and 0.004mol of cobalt sulfate in 20mL of deionized water and glycerol mixed solution (the ratio of deionized water to glycerol is 2:1) , st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com