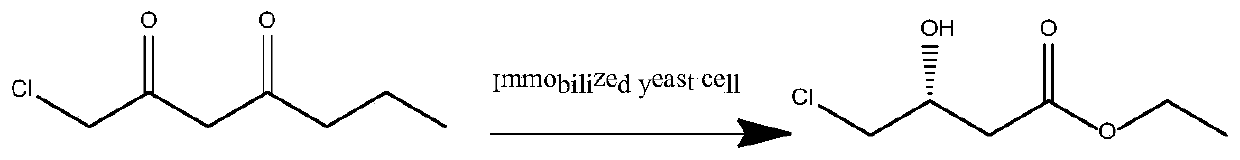

Magnetic immobilized yeast cell and application thereof to synthesis of ethyl R-4-chloro-3-hydroxybutyrate

A technology of ethyl hydroxybutyrate and immobilized yeast, which is applied in the direction of immobilized on or in the inorganic carrier, based on microorganism methods, fermentation, etc., can solve the problem of low substrate processing capacity, improve transformation efficiency, and facilitate Recycling and reuse, improving the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of Saccharomyces cerevisiae cells

[0036] (1) Slant culture: Saccharomyces cerevisiae CGMCC No.3361 was inoculated into the slant medium, and cultivated at 37°C for 24 hours to obtain a slant; the slant medium was prepared as follows: wort juice 10g / L, yeast Powder 3g / L, peptone 5g / L, glucose 10g / L, agar 20g / L, natural pH value, solvent is water; sterilize at 121°C for 20min, cool down after sterilization to make a slope;

[0037] (2) Seed culture: Take a ring of thalline from the thalline slope and transfer it to the seed culture medium, at 35°C, the shaking table speed is 150r / min, cultivate for 24h, and obtain the seed liquid; the described seed culture medium is prepared according to the following composition : Glucose 30g / L, yeast powder 3g / L, ammonium sulfate 5g / L, anhydrous MgSO 4 0.3g / L, K 2 HPO 4 ·3H 2 O 1.0g / L, KH 2 PO 4 1.0g / L, natural pH value, solvent is water;

[0038] (3) Fermentation culture: get seed liquid, inoculate in...

Embodiment 2

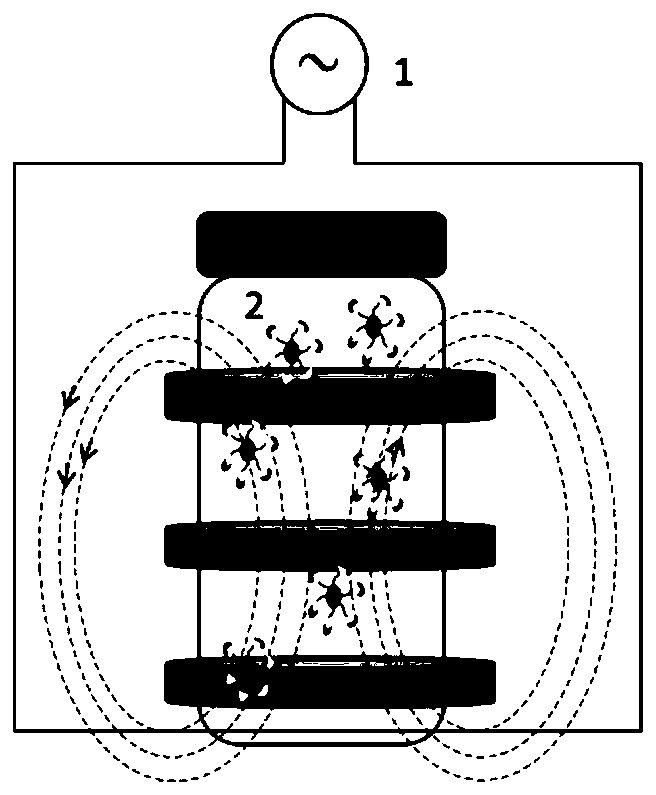

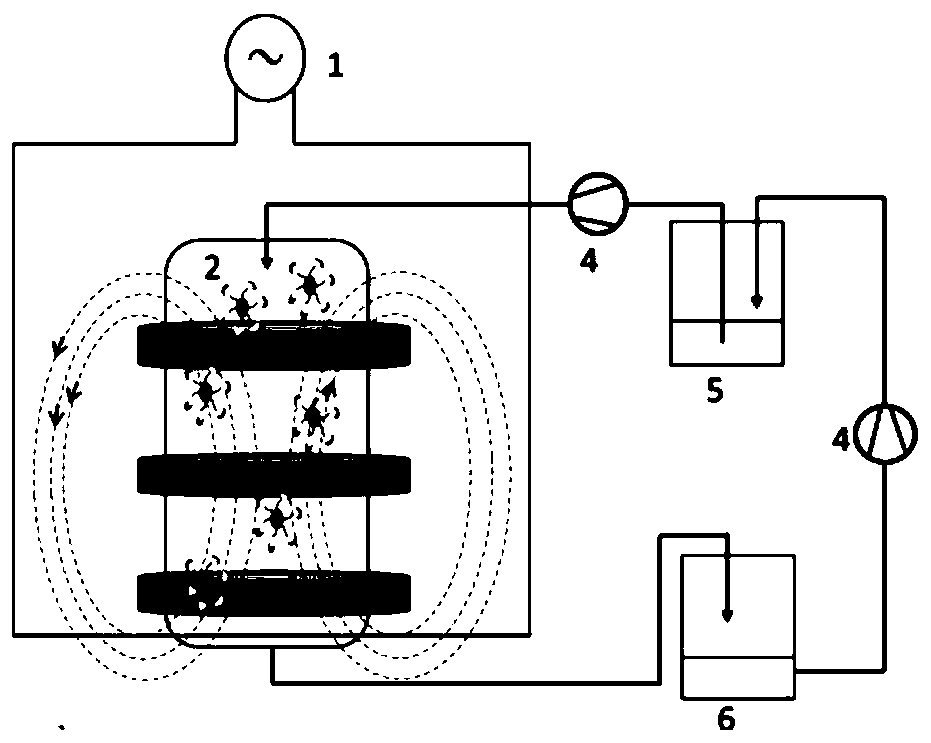

[0039] Example 2: Preparation of magnetically immobilized cells

[0040] (1) Weigh 12.675g FeCl 2 Dissolved in 1000mL deionized water, configured as 0.1M FeCl 2 Solution, weigh 16.220g FeCl 3 Dissolved in 1000mL deionized water, configured as 0.1M FeCl 3 solution. FeCl 2 Solution 30mL, FeCl 3 Mix 60mL of the solution into a 250mL three-neck flask, add 20mL of deionized water, and stir at 1000rpm at a high speed, keep a water bath at 30-40°C, slowly add ammonia water dropwise to adjust the pH to 10, and the solution turns black and shiny. Raise the temperature to 60°C and react for 1h. Then raise the temperature to 80°C and ripen for 1h. After the reaction was finished, it was cooled to room temperature, and it was repeatedly washed with deionized water until it was colorless and transparent, and the pH of the supernatant was neutral, and collected by an external magnetic field to obtain a black magnetic particle precipitate (Fe 3 o 4 ), pre-frozen in -80°C refrigerato...

Embodiment 3

[0046] Embodiment 3: the influence of immobilization time on immobilization rate

[0047] (1) In five 50 mL small Erlenmeyer flasks, 3 g of the dry yeast prepared by the method in Example 1 were fully dissolved in 20 mL of phosphate buffered saline (pH 9), and 0.01 g of carrier Fe was added 3 o 4 -Arg, mixed evenly, no carrier was added to the other five Erlenmeyer flasks as a control group, fixed at 30°C for 2 h, 3 h, 4 h, 5 h, and 6 h in a shaker shaker at 150 r / min. After the reaction, the reaction solution was recovered by an external magnetic field, and the ultraviolet absorption value of the 10-fold diluted upper layer at a wavelength of 260 nm was used as A 1 value, the UV absorbance value of the control group diluted 10 times at the same time as A 0 , and the average immobilization rate is shown in Table 2. Immobilization rate AD = (A 0 -A 1 ) / A 0 ×100%.

[0048] (2) In five 50 mL small Erlenmeyer flasks, fully dissolve 3 g of the dry yeast prepared by the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com