A kind of flame retardant with capsule core structure and its preparation method and application

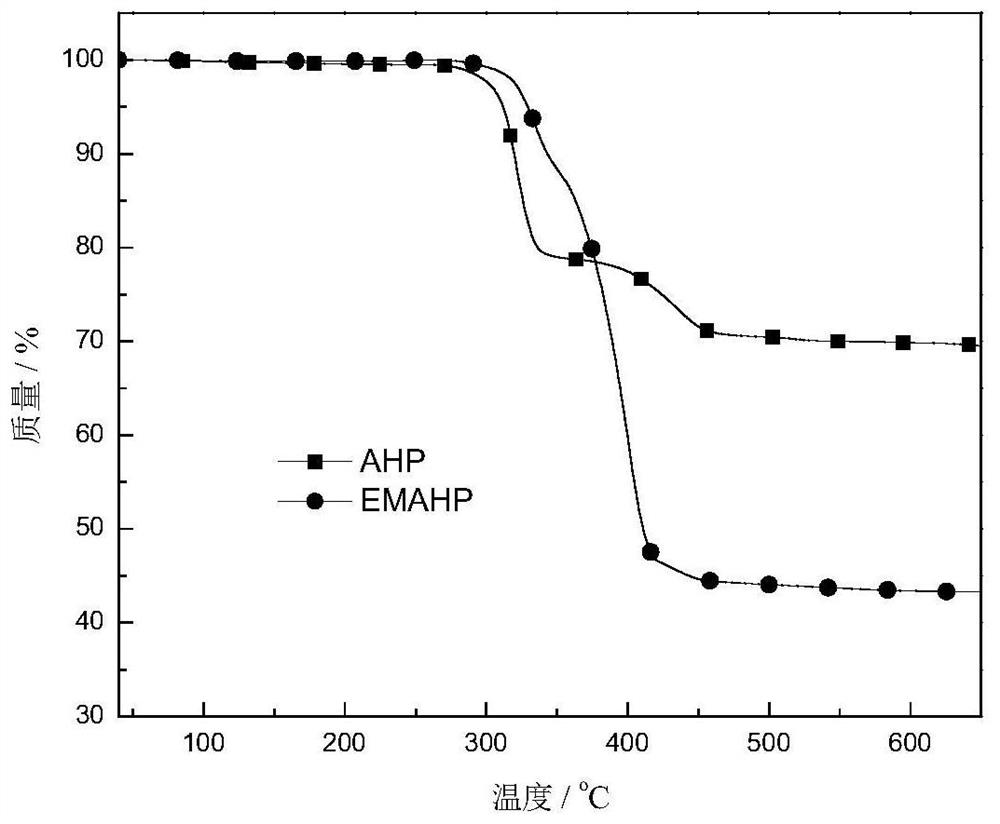

A technology of flame retardant and capsule core, which is applied in the field of flame retardant with capsule core structure and its preparation, can solve the problems of poor compatibility of polymer materials, poor water resistance of aluminum hypophosphite, poor flame retardant effect, etc., to achieve flame retardant Good flammability, low cost, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

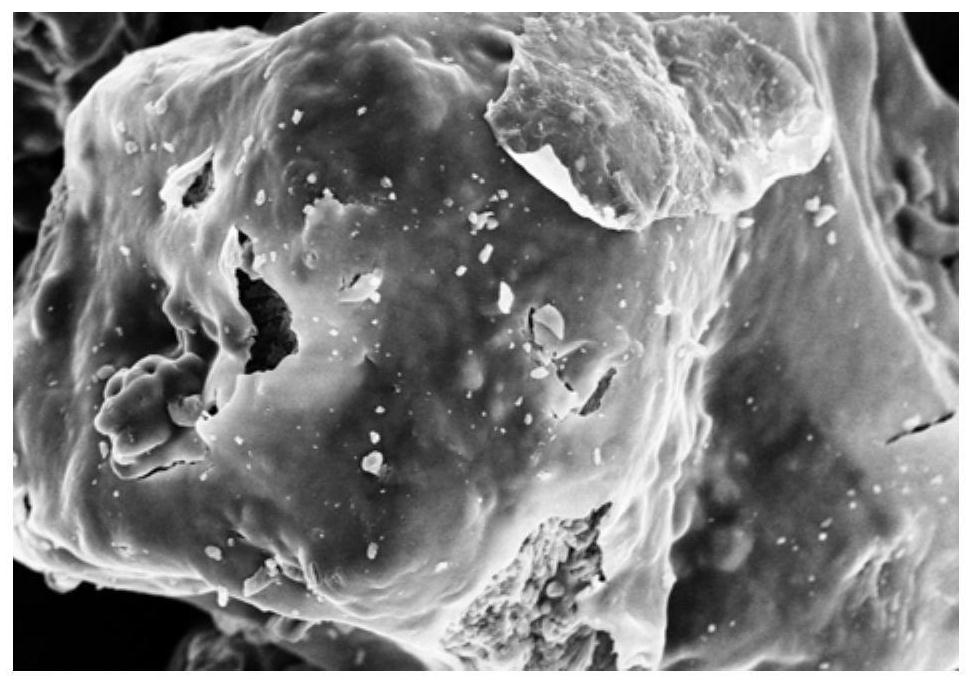

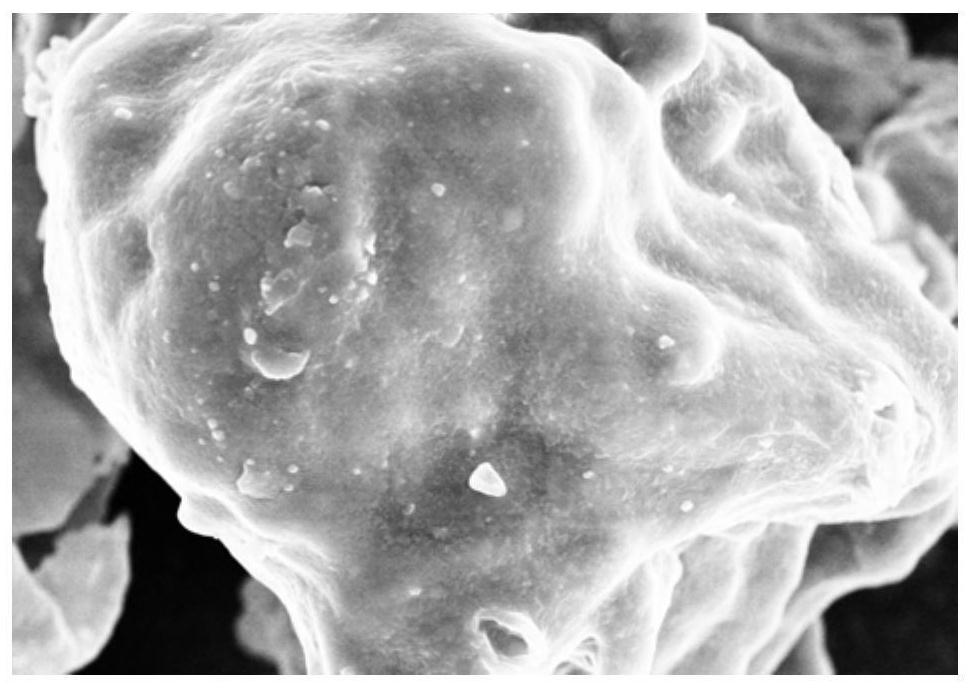

[0034] A preparation method of a flame retardant with a capsule-core structure, the specific steps are as follows:

[0035] (1) Mix aluminum hypophosphite and water, stir at 15°C for 1.2h to obtain a dispersion;

[0036](2) first add melamine to the dispersion liquid, stir for 1 hour at a temperature of 60° C., then continue to add cyanuric acid, and then carry out post-treatment to obtain a self-assembled product after stirring for 3 hours at a temperature of 105° C.; The molar ratio of cyanuric acid is 1:1;

[0037] (3) Mix the self-assembly product, bisphenol A diglycidyl ether and ethylene glycol, stir at 15°C for 1.2h, add fatty amine (triethylenetetramine), and stir at 70°C for 3h to After bisphenol A diglycidyl ether reacts with aliphatic amine to generate organic resin, post-treatment (filtering, drying, crushing) is carried out to obtain a flame retardant with a capsule-core structure, and the solubility of the flame retardant in water is 0.1g / 100 grams of water , t...

Embodiment 2

[0053] A preparation method of a flame retardant with a capsule-core structure, the specific steps are as follows:

[0054] (1) Mix aluminum hypophosphite and water, stir at 25°C for 0.1h to obtain a dispersion;

[0055] (2) First add melamine to the dispersion, stir for 2 hours at a temperature of 50°C, then continue to add phosphoric acid, and then carry out post-processing to obtain a self-assembled product after stirring at a temperature of 90°C for 6 hours; melamine and phosphoric acid The molar ratio is 1:1;

[0056] (3) Mix self-assembly product, bisphenol A diglycidyl ether and methanol, stir at 25°C for 0.1h, then add modified fatty amine (cardanol modified amine curing agent, also known as natural long-chain substituted phenalkamine curing agent , Brand: RQ-1021, Shandong Runqi Biotechnology Co., Ltd.), stirred at a temperature of 30°C for 6 hours until bisphenol A diglycidyl ether reacted with fatty amine to form an organic resin, and after post-treatment to obtain...

Embodiment 3

[0059] A preparation method of a flame retardant with a capsule-core structure, the specific steps are as follows:

[0060] (1) Mix aluminum hypophosphite and acetonitrile, stir at 25°C for 0.5h to obtain a dispersion;

[0061] (2) First add melamine to the dispersion liquid, stir for 1.5h at a temperature of 54°C, then continue to add hypophosphorous acid, and after stirring for 5h at a temperature of 80°C, perform post-processing to obtain a self-assembled product; melamine The molar ratio with hypophosphorous acid is 1:1;

[0062] (3) Mix the self-assembly product, bisphenol A diglycidyl ether and ethylene glycol, stir at 25°C for 0.6h, then add aromatic amine (4,4'-diaminodiphenylsulfone), at a temperature of 70°C Stir for 5 hours under certain conditions until bisphenol A diglycidyl ether reacts with aromatic amine to form an organic resin, and then perform post-treatment to obtain a flame retardant with a capsule-core structure. The solubility of the flame retardant in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com