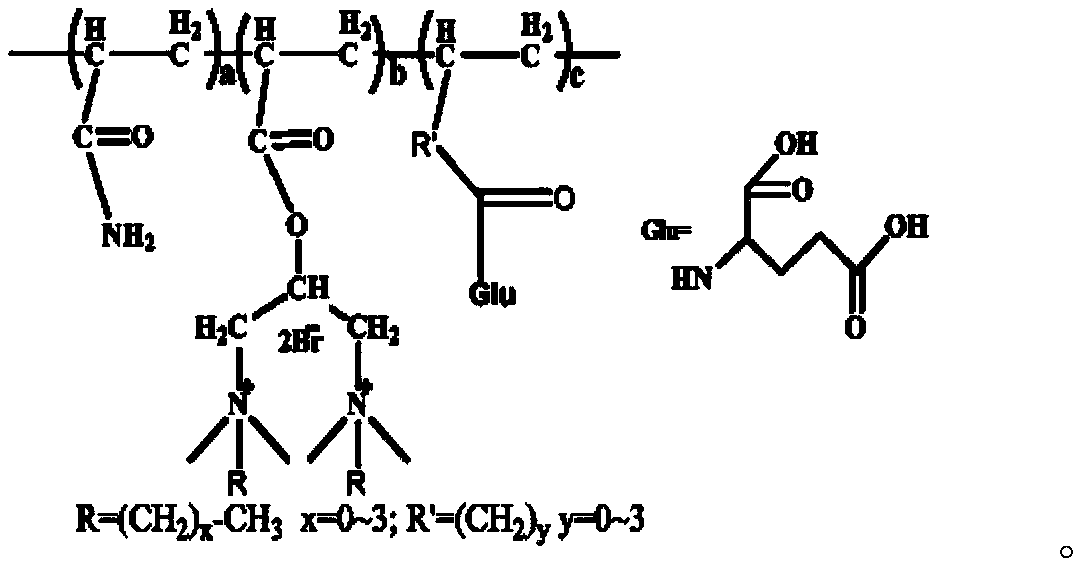

Novel amphoteric acrylamide polymer flocculant and preparation method thereof

A technology of acrylamide and acrylamide monomers, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long dissolution time, weakened particle adsorption capacity, pH value Sensitivity and other problems, to achieve the effect of significant flocculation effect, short dissolution time and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

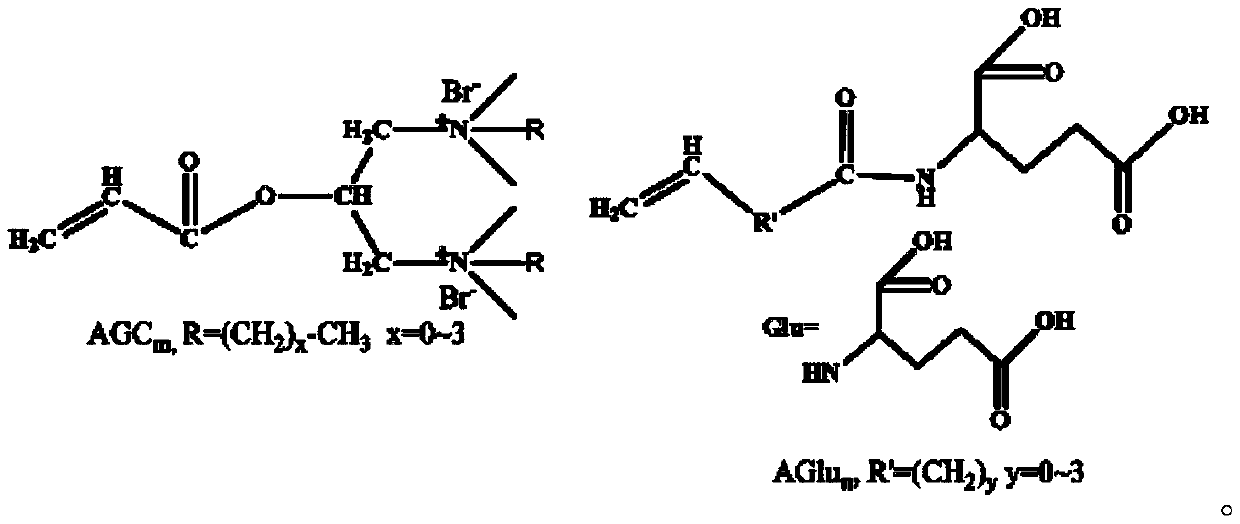

[0027] 1. AGC 1 The synthesis of includes the following steps:

[0028] (1) Add 0.06mol 1,3-bis(dimethylamino)propan-2-alcohol solution and 50ml chloroform solution in a 150ml single-necked flask, add catalyst 4-dimethylaminopyridine (DMAP), acid-binding agent It is 0.09mol triethylamine solution, under ice bath conditions, the temperature is controlled below 5°C, take 0.09mol acryloyl chloride solution and slowly add it dropwise into the flask from a constant pressure dropping funnel, after the dropwise addition, react at room temperature for 24 hours, and then in 40 The reaction was carried out at ℃ for 48h. After the product was spin-dried by a rotary evaporator, it was recrystallized three times through ether, and the solid triethylamine hydrochloride was removed by suction filtration, and the filtered liquid was rotary evaporated to obtain a yellow liquid 1,3-bis(dimethylamino)propane-2- base acrylate. (2) Take 0.1mol of the product obtained in (1) and place it in a 25...

Embodiment 2

[0037] AGC 2 and AGlu 2 Preparation process is with example 1. The synthesis of novel amphoteric polyacrylamide comprises the following steps:

[0038] (1) The polymer is composed of acrylamide monomer (AM) and AGC 2 and AGlu 2 Prepared by ternary copolymerization, in the mixed aqueous solution configured by monomers, the total mass ratio of monomers is 25%, the molar ratio of AM monomers is 85%, AGC 2 and AGlu 2 The molar ratio between them is 1:4.

[0039] (2) Add 4g of auxiliary methanol, 0.004g of chelating agent ethylenediaminetetraacetic acid (EDTA), and 0.006g of chain transfer agent sodium formate into the system, and continuously feed high-purity nitrogen for 30 minutes to remove dissolved oxygen in water, and the temperature of the system is raised to After 40°C, 0.06 g of initiator azobisisobutylamidine hydrochloride (VA-044) was added to carry out polymerization reaction. After 2 hours of reaction, the temperature of the system was raised to 60°C, and the rea...

Embodiment 3

[0042] AGC 3 and AGlu 3 Preparation process is with example 1.

[0043] The synthesis of novel amphoteric polyacrylamide comprises the following steps:

[0044] (1) The polymer is composed of acrylamide monomer (AM), AGC 3 and AGlu 3 Prepared by ternary copolymerization, in the mixed aqueous solution configured by monomers, the total mass ratio of monomers is 30%, the molar ratio of AM monomers is 90%, AGC 3 and AGlu 3 The molar ratio between them is 1:5.

[0045] (2) Add 4g of auxiliary methanol, 0.004g of chelating agent ethylenediaminetetraacetic acid (EDTA), and 0.006g of chain transfer agent sodium formate into the system, and continuously feed high-purity nitrogen for 30 minutes to remove dissolved oxygen in water, and the temperature of the system is raised to After 40°C, 0.07 g of initiator azobisisobutylamidine hydrochloride (VA-044) was added to carry out polymerization reaction. After 2 hours of reaction, the temperature of the system was raised to 60°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com