A silicon-based negative electrode material and its preparation method and use

A silicon-based negative electrode material and silicon-based technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of difficult large-scale industrial production, insufficient performance improvement, and complicated preparation process, and achieve improved structure and cycle stability properties, improved interface stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

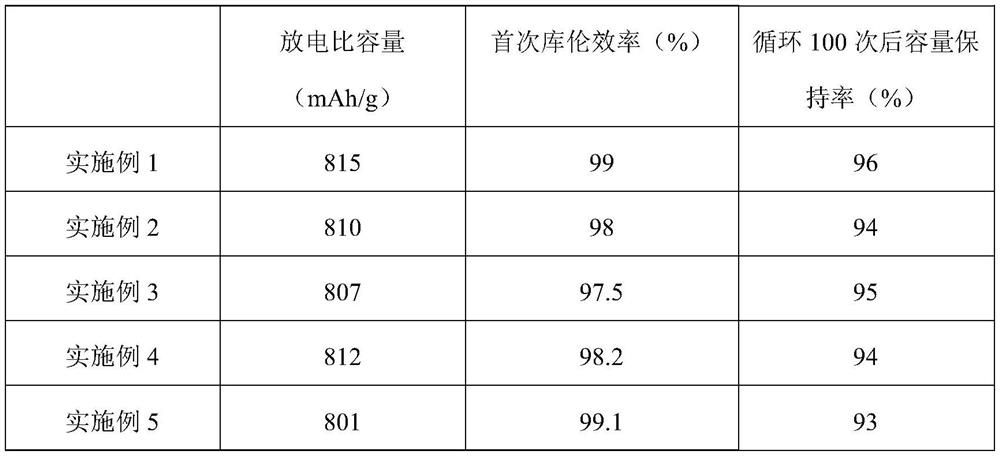

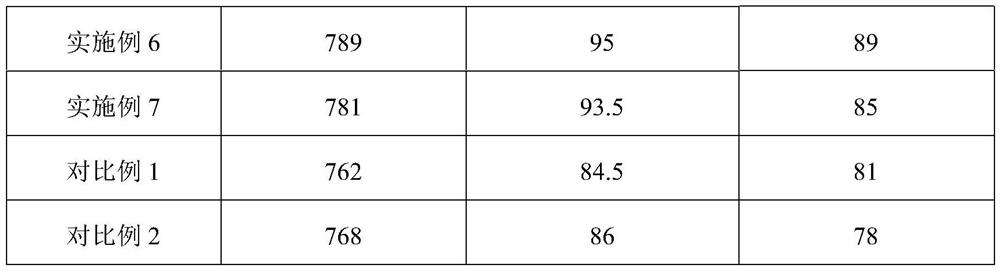

Examples

Embodiment 1

[0085]This embodiment provides a silicon-based negative electrode material and a preparation method thereof. Taking the mass of the silicon-based negative electrode material as 100%, the mass percentage of the silicon-based core is 45%, and the mass percentage of the first coating is 40%, the mass percentage of the second coating is 15%; the second coating is obtained by carbonization of polydopamine, triblock copolymer and tromethamine;

[0086] The silicon-based negative electrode material is prepared by the following method:

[0087] (I) Preparation of the first coating:

[0088] According to a certain ratio of Li 1.81 h 0.19 Ti 2 o 5 ·H 2 O and hexagonal phase tungsten oxide nanowires were added to the aqueous dispersion of graphene (concentration 1.2mg / mL), so that graphene, Li 1.81 h 0.19 Ti 2 o 5 ·H 2 The mass percentage of O and hexagonal tungsten oxide nanowires is 95%:3%:2%, stirred at a rate of 300r / min for 5h, then ultrasonically treated for 1h, and the u...

Embodiment 2

[0095] This embodiment provides a silicon-based negative electrode material and a preparation method thereof. Taking the mass of the silicon-based negative electrode material as 100%, the mass percentage of the silicon-based core is 65%, and the mass percentage of the first coating is 25%, the mass percentage of the second coating is 10%; the second coating is obtained by carbonization of polydopamine, triblock copolymer and tromethamine;

[0096] The silicon-based negative electrode material is prepared by the following method:

[0097] (I) Preparation of the first coating:

[0098] According to a certain ratio of Li 1.81 h 0.19 Ti 2 o 5 ·3H 2 O and hexagonal phase tungsten oxide nanorods were added to the aqueous dispersion of graphene (concentration 2mg / mL), so that graphene, Li 1.81 h 0.19 Ti 2 o 5 ·3H 2 The mass percentage of O and hexagonal phase tungsten oxide nanorods is 60%:30%:10%, stirred at a rate of 600r / min for 1h, then ultrasonically treated for 4h, an...

Embodiment 3

[0105] This embodiment provides a silicon-based negative electrode material and a preparation method thereof. Taking the mass of the silicon-based negative electrode material as 100%, the mass percentage of the silicon-based core is 75%, and the mass percentage of the first coating is 20%, the mass percentage of the second coating is 5%; the second coating is obtained by carbonization of polydopamine, triblock copolymer and tromethamine;

[0106] The preparation method of the silicon-based negative electrode material:

[0107] (I) Preparation of the first coating:

[0108] According to a certain ratio, the phase structure contains H at the same time 2 Ti 3 o 7 , Li 4 Ti 5 o 12 and TiO 2 The compound and hexagonal phase tungsten oxide nanoparticles are added to the graphene water dispersion (concentration 1.5mg / mL), so that the graphene and the phase structure simultaneously contain H 2 Ti 3 o 7 , Li 4 Ti 5 o 12 and TiO 2 The compound, the mass percentage of hexag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com