Porcelain insulator with high cold resistance and preparation method thereof

A porcelain insulator and cold-resistant technology, applied in the field of high-cold-resistant porcelain insulators and their preparation, can solve problems such as railway line paralysis, and achieve the effects of reducing melting temperature, low thermal conductivity, specific heat and mechanical vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

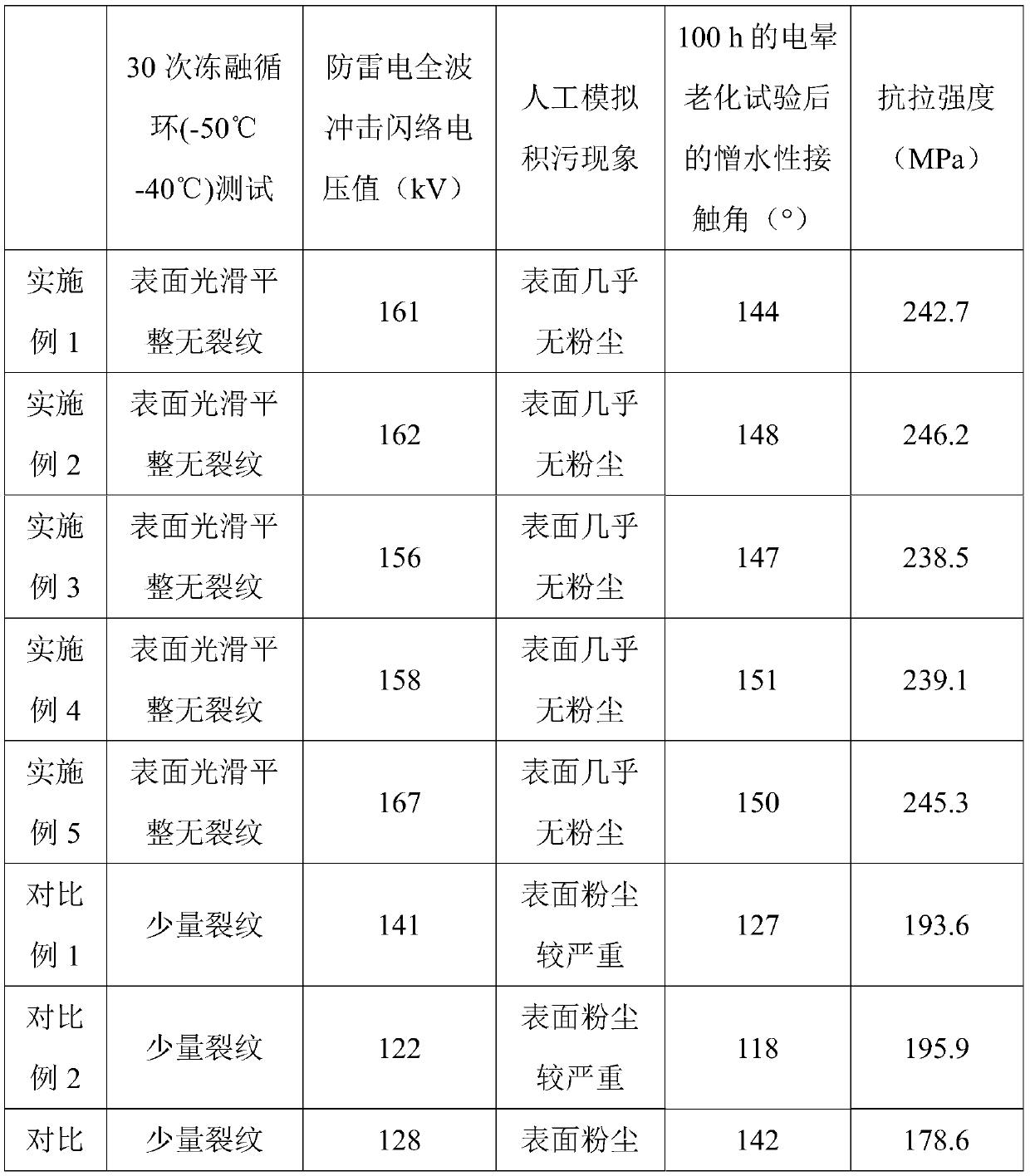

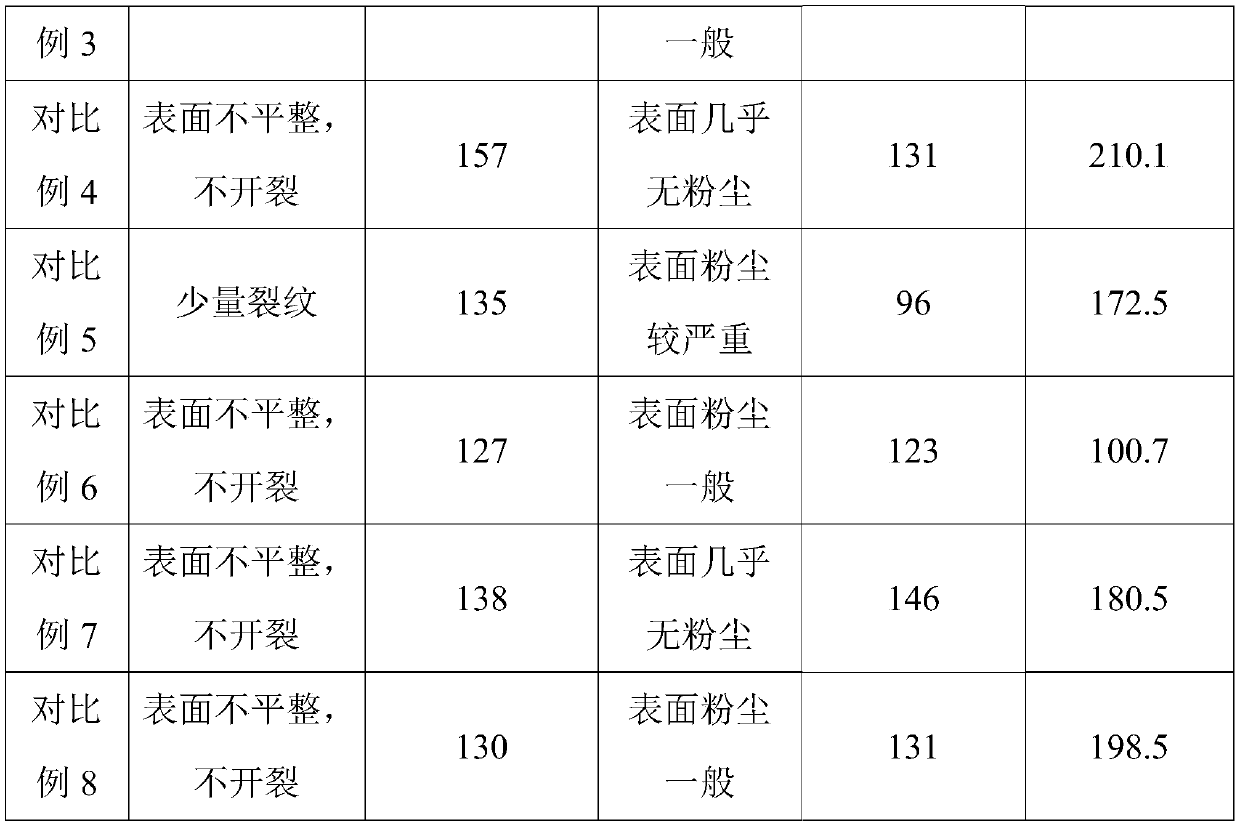

Examples

Embodiment 1

[0050] A porcelain insulator with high cold resistance, its formula includes the following raw materials in parts by weight: 23 parts of Banshan clay, 25 parts of Changfeng clay, 12 parts of illite, 18 parts of bauxite, 10 parts of molecular sieve, 10 parts of bentonite, and 18 parts of zirconia 10 parts of calcium phosphate fiber, 5 parts of ceramic fiber, 10 parts of silicon carbide fiber, 3 parts of boric acid, 8 parts of modified nano titanium dioxide-silicon powder additive, 2 parts of sepiolite powder, 2 parts of dodecyl silane, twelve parts 2 parts of sodium alkyl sulfate, 2 parts of sodium nitrate, 2 parts of sodium carbonate, and 2 parts of sodium sulfate.

[0051] A method for preparing a high cold resistance porcelain insulator, comprising the following steps:

[0052] S1. Preparation of modified nano-titanium dioxide-silica powder additive: Add nano-titanium dioxide, dispersant Dow Corning 51, defoamer Dow Corning 65 and wetting agent GSK-588 into deionized water, ...

Embodiment 2

[0062] A porcelain insulator with high cold resistance, its formula includes the following raw materials in parts by weight: 30 parts of Banshan clay, 15 parts of Changfeng clay, 22 parts of illite, 10 parts of bauxite, 16 parts of molecular sieve, 16 parts of bentonite, and 18 parts of zirconia 16 parts of calcium phosphate fiber, 5 parts of boron nitride fiber, 12 parts of boric acid, 8 parts of modified nano titanium dioxide-silicon powder additive, 7 parts of sepiolite powder, 2 parts of aminopropyl triethoxysilane, glycidyl ether 2 parts of oxypropyltrimethoxysilane, 2 parts of vinyltrimethoxysilane, 3 parts of ammonium lauryl sulfate, 3 parts of fatty alcohol polyoxyethylene ether sodium sulfate, and 2 parts of potassium sulfate.

[0063] A method for preparing a high cold resistance porcelain insulator, comprising the following steps:

[0064] S1. Preparation of modified nano-titanium dioxide-silica powder additive: Add nano-titanium dioxide, dispersant EFKA SL3034, def...

Embodiment 3

[0074] A porcelain insulator with high cold resistance, its formula includes the following raw materials in parts by weight: 28 parts of Banshan clay, 20 parts of Changfeng clay, 15 parts of illite, 16 parts of bauxite, 12 parts of molecular sieve, 15 parts of bentonite, and 15 parts of zirconia 12 parts of calcium phosphate fiber, 3 parts of boron nitride fiber, 7 parts of asbestos fiber, 10 parts of boric acid, 3 parts of modified nano titanium dioxide-silicon powder additive, 5 parts of sepiolite powder, 2 parts of thiopropyltrimethoxysilane 3 parts, 3 parts of vinyl triethoxysilane, 2 parts of sodium lauryl sulfate, 3 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 3 parts of sodium nitrite.

[0075] A method for preparing a high cold resistance porcelain insulator, comprising the following steps:

[0076]S1. Preparation of modified nano-titanium dioxide-silica powder additive: Add nano-titanium dioxide, dispersant EFKA SL3034, defoamer Deform 6800 and wetti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com