Composite remediation agent for organic contaminated soil as well as preparation method and application of composite remediation agent

An organic pollution and composite technology, applied in the field of soil remediation, can solve problems such as ineffective cohesive soil, uneven distribution of soil layer injection, iron pollution, etc., to improve soil comprehensive ability, increase crop stress resistance, and increase phosphorus The effect of elemental content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

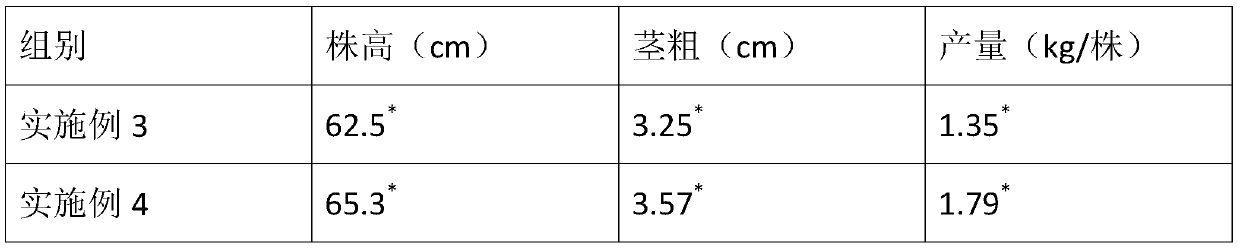

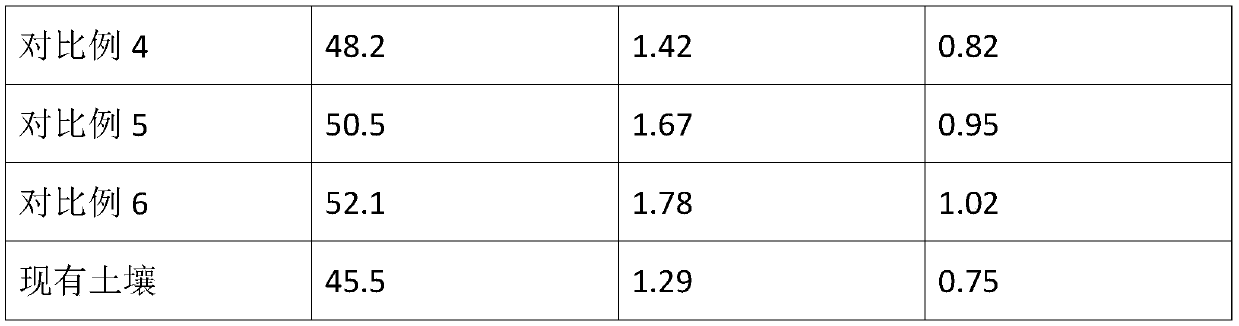

Examples

Embodiment 1

[0033] Biochar is modified straw, the preparation method is as follows:

[0034] S1. crush the straw, soak it with 5wt% alkali solution for 10h, wash it, and dry it;

[0035] S2. after soaking with 0.5mol / L acid solution for 5h, wash and dry;

[0036] S3. Soak in 3wt% hydrogen peroxide solution for modification reaction for 3 hours, and wash after the reaction;

[0037] S4. Put the modified straw powder into a muffle furnace for high-temperature carbonization under nitrogen protection. The temperature is raised by 10° C. every 5 minutes, up to 850° C., and the temperature is lowered after carbonization for 30 minutes to obtain the modified straw.

Embodiment 2

[0039] Biochar is modified straw, the preparation method is as follows:

[0040] S1. crush the stalks, soak them in 10wt% alkali solution for 20 hours, wash them, and dry them;

[0041] S2. After soaking with 1mol / L acid solution for 10h, wash and dry;

[0042] S3. Soak in 5wt% hydrogen peroxide solution for modification reaction for 7 hours, and wash after the reaction;

[0043] S4. Put the modified straw powder into a muffle furnace for high-temperature carbonization under nitrogen protection. The temperature is raised by 10° C. every 5 minutes, up to 850° C., and the temperature is lowered after carbonization for 30 minutes to obtain the modified straw.

Embodiment 3

[0061] Composition of raw materials (parts by weight): 10 parts of biochar prepared in Example 1, 50 parts of straw powder, 0.5 part of sodium selenite, 10 parts of wood vinegar, 2 parts of rice washing water, 10 parts of enzyme components, microbial components 15 parts, 30 parts of fertilizer and 5 parts of ferrous chloride solution of 12wt%.

[0062] Enzyme components include (parts by weight) 1 part of urease, 3 parts of catalase, 2 parts of sucrase, 1 part of protease, 3 parts of dehydrogenase, 3 parts of phosphatase, 1 part of glucose oxidase, and 1 part of aldehyde oxidase , 2 parts of uric acid oxidase, 2 parts of biphenyl oxidase, 2 parts of carboxyl esterase, 1 part of aryl esterase, 5 parts of esterase, 5 parts of phosphatase, 3 parts of nucleoesterase, 2 parts of nucleotidase 3 parts of dextran sucrase, 5 parts of fructan sucrase, 3 parts of aminotransferase, 1 part of aspartic acid decarboxylase, 2 parts of glutamic acid decarboxylase, 1 part of aromatic amino acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com