Marine polysaccharide water-based resin and preparation method thereof

A water-based resin and polysaccharide technology, applied in coating and other directions, can solve the problems of complex production process and insufficient functional utilization of raw materials, and achieve the effects of improving the degree of cross-linking, being easily soluble in water, and having a simple toning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

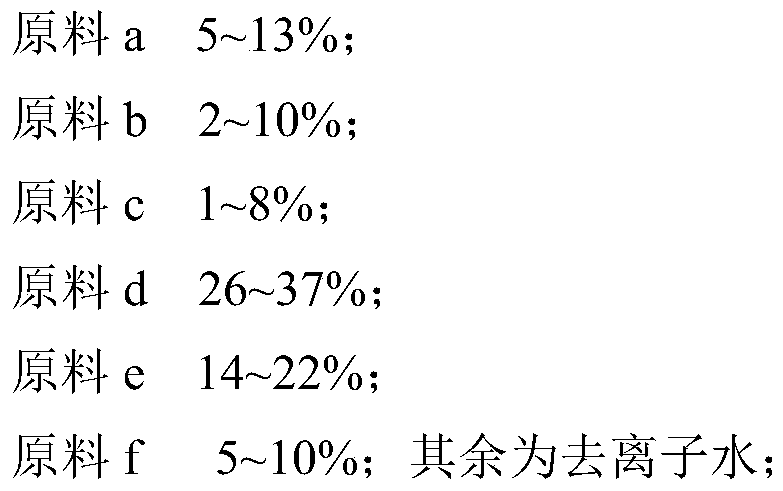

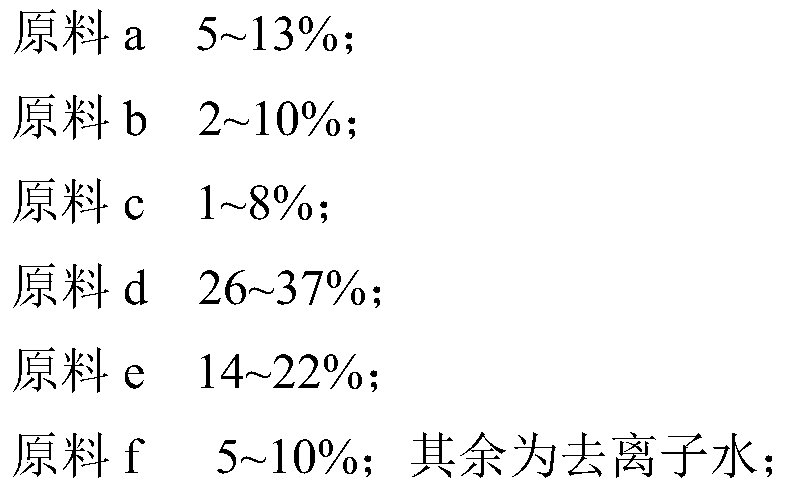

[0032] A marine polysaccharide water-based resin, comprising the following components by weight percentage: raw material a6.5% (triethylamine); raw material b7.8% (choose methyl methacrylate as raw material b in this embodiment, certainly also Ethyl methacrylate, isopropyl methacrylate, isobutyl methacrylate, tert-butyl methacrylate, isooctyl methacrylate, n-octyl methacrylate, cyclohexyl methacrylate, Isobornyl methacrylate, etc. have the same effect); raw material c2.3% (in this embodiment, monoethanolamine is selected as raw material c, and of course alcoholamines such as diethanolamine and triethanolamine with similar properties can also be used); Raw material d35.6% (select chitosan in the present embodiment); Raw material e20.2% (propylene glycol methyl ether acetate); Raw material f6.7% (acrylic acid); All the other are deionized water.

[0033] The preparation method of the above-mentioned marine polysaccharide water-based resin is as follows: add raw material a and raw ...

Embodiment 2

[0036] A marine polysaccharide water-based resin, comprising the following components by weight percentage: raw material a11.2% (triethanolamine); raw material b4.5% (choose ethyl acrylate in the present embodiment, as raw material b, certainly also can be selected for use Methyl acrylate, n-butyl acrylate, hydroxypropyl acrylate, isooctyl acrylate, etc.); raw material c5.1% (acetamide is selected for use in this embodiment, and dimethylformamide, isobutyramide, etc. can also be used certainly); Raw material d27.9% (select gelatin in the present embodiment); Raw material e15.6% (for ethylene glycol monobutyl ether, certainly also can adopt other ethers raw materials as auxiliary solvent); Raw material f7.4% (methacrylic acid ); the rest is deionized water.

[0037] The preparation method of the above-mentioned marine polysaccharide water-based resin is as follows: add raw material a and raw material b into a four-neck flask, raise the temperature to 43°C, stir for 3 hours, the...

Embodiment 3

[0040] A marine polysaccharide water-based resin, comprising the following components by weight percentage: raw material a7.5% (hexamethyleneimine); raw material b6.6% (the present embodiment selects ethylene carbonate, certainly also can select carbonic acid propylene ester); raw material c2.2% (select aniline in the present embodiment, certainly also can adopt o-phenylenediamine, 2,4-dimethylaniline, N, N-diethylaniline, p-fluoroaniline etc.); Raw material d33.6% (sodium alginate is selected in this embodiment); raw material e16.6% (vinyl ethyl ether); raw material f9.7% (acrylic acid); the rest is deionized water.

[0041] The preparation method of the above-mentioned marine polysaccharide water-based resin is as follows: add raw material a and raw material b into a four-neck flask, heat up to 56°C, stir for 4 hours, then heat up to 88°C, add raw material c and raw material d, stir for 5 hours, then add raw material e , raw material f, deionized water, continue to keep warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com