High-performance polyimide film and preparation method thereof

A polyimide film and polyimide resin technology, applied in the field of high-performance polyimide film and its preparation, can solve the problems of decreased mechanical properties, stress concentration, increased light scattering ratio, etc., and achieve excellent mechanical and The effect of improving thermal performance, comprehensive performance, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

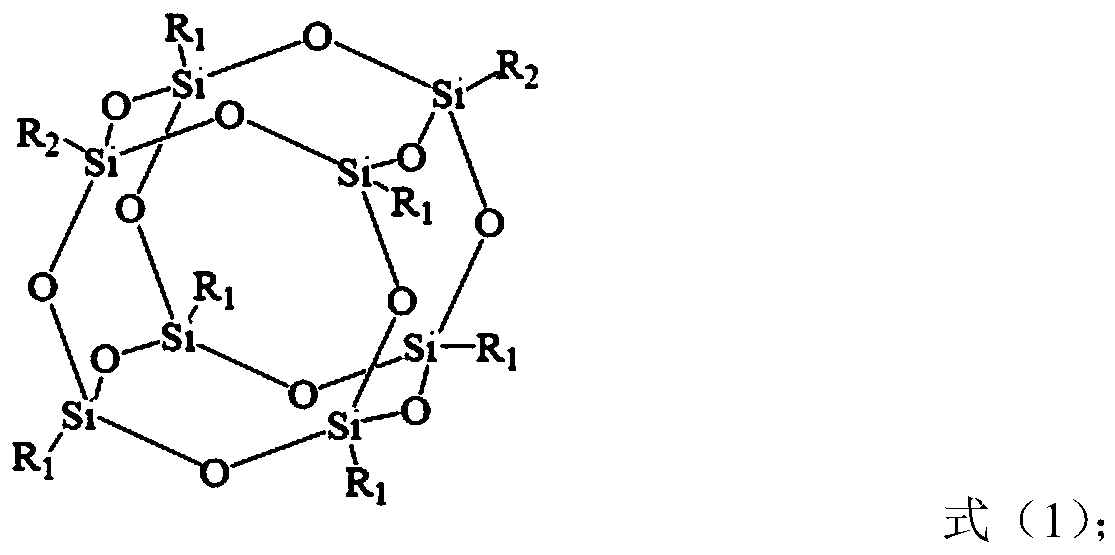

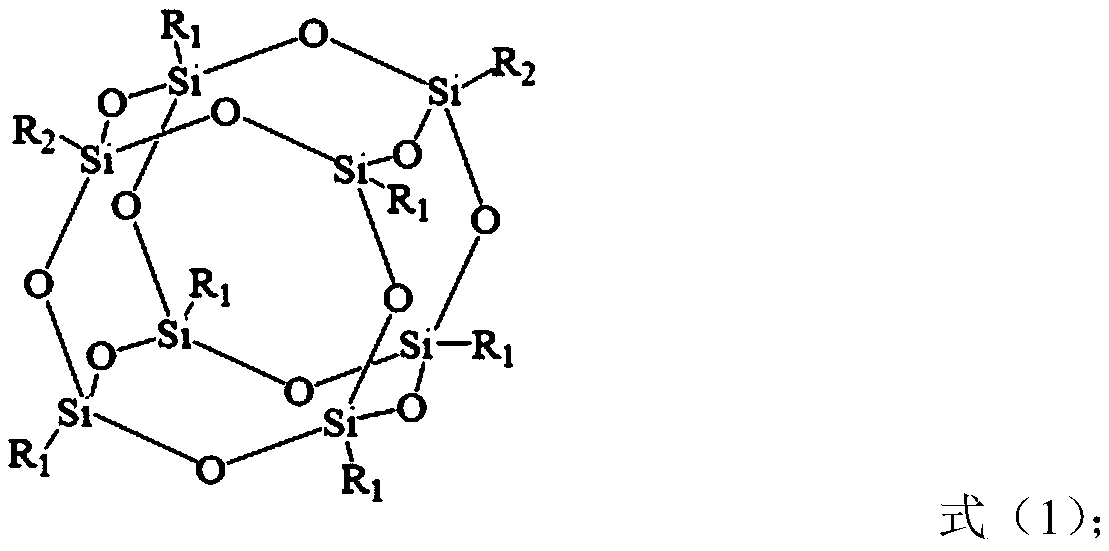

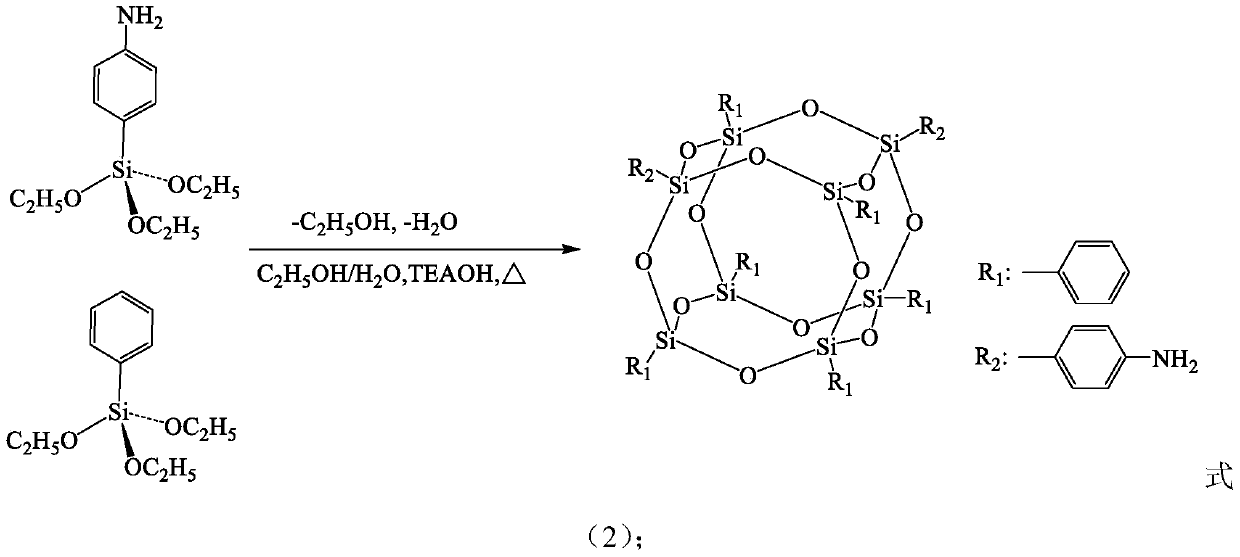

[0050] A preparation method of high-performance polyimide film of the present invention, comprises the following steps:

[0051] (1) Under an inert atmosphere, add 10.64g (0.01mol) bis(4-anilino)-hexaphenyl-POSS, 10.89g (0.034mol) to a polymerization bottle equipped with a mechanical stirrer and a water separator TFMB, 1.82g (0.005mol) 1,1-bis(4-aminophenyl)-1-(4-ethynylphenyl)-2,2,2-trifluoroethane and 80g m-cresol, stirred to After complete dissolution, add 17.77g (0.04mol) 6FDA, 2.94g (0.01mol) BPDA and 23g m-cresol, then raise the temperature to 70°C for 6 hours, then add 0.234g (0.002mol) monoamine EAL, and stir for 3 hours Add 2.21g (5wt%) benzoic acid to promote the reaction, then raise the temperature to 175°C for 18h, and at the same time increase the nitrogen flow rate, remove the water generated by polymerization in time from the polymerization system, and after the reaction is completed and cool to room temperature, a polyimide resin is obtained solution;

[0052...

Embodiment 2

[0084] A preparation method of high-performance polyimide film of the present invention, comprises the following steps:

[0085] (1) Under an inert atmosphere, place a polymerization bottle equipped with a mechanical stirrer in a refrigerant liquid at 0°C, and first add 10.64g (0.01mol) of bis(4-anilino)-hexaphenyl-POSS, 10.89g (0.034mol) TFMB, 1.82g (0.005mol) 1,1-bis(4-aminophenyl)-1-(4-ethynylphenyl)-2,2,2-trifluoroethane and 80g DMAc, After stirring until completely dissolved, add 17.77g (0.04mol) 6FDA, 2.94g (0.01mol) BPDA and 50g DMAc, stir for 6h and then add 0.234g (0.002mol) monoamine EAL, then stir at 0°C for 10h, then Raise the temperature to 100°C for 4 hours to complete the imidization and obtain a viscous polyamic acid solution;

[0086] (2) Add 46g DMAc to the polyamic acid solution to dilute it, then add 12.76g (0.125mol) acetic anhydride, add 6.46g (0.05mol) quinoline after stirring for 0.5h, stir at 0°C for 6h, transfer into an oil bath, heated to 100°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com