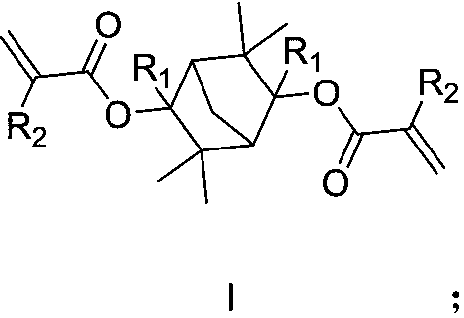

Photoresist resin monomer and synthesis method thereof

A technology of resin monomer and synthesis method, applied in the field of photoresist resin monomer and its synthesis, can solve the problem of low resolution of photolithography pattern, and achieve the effects of improving resolution, improving edge roughness and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

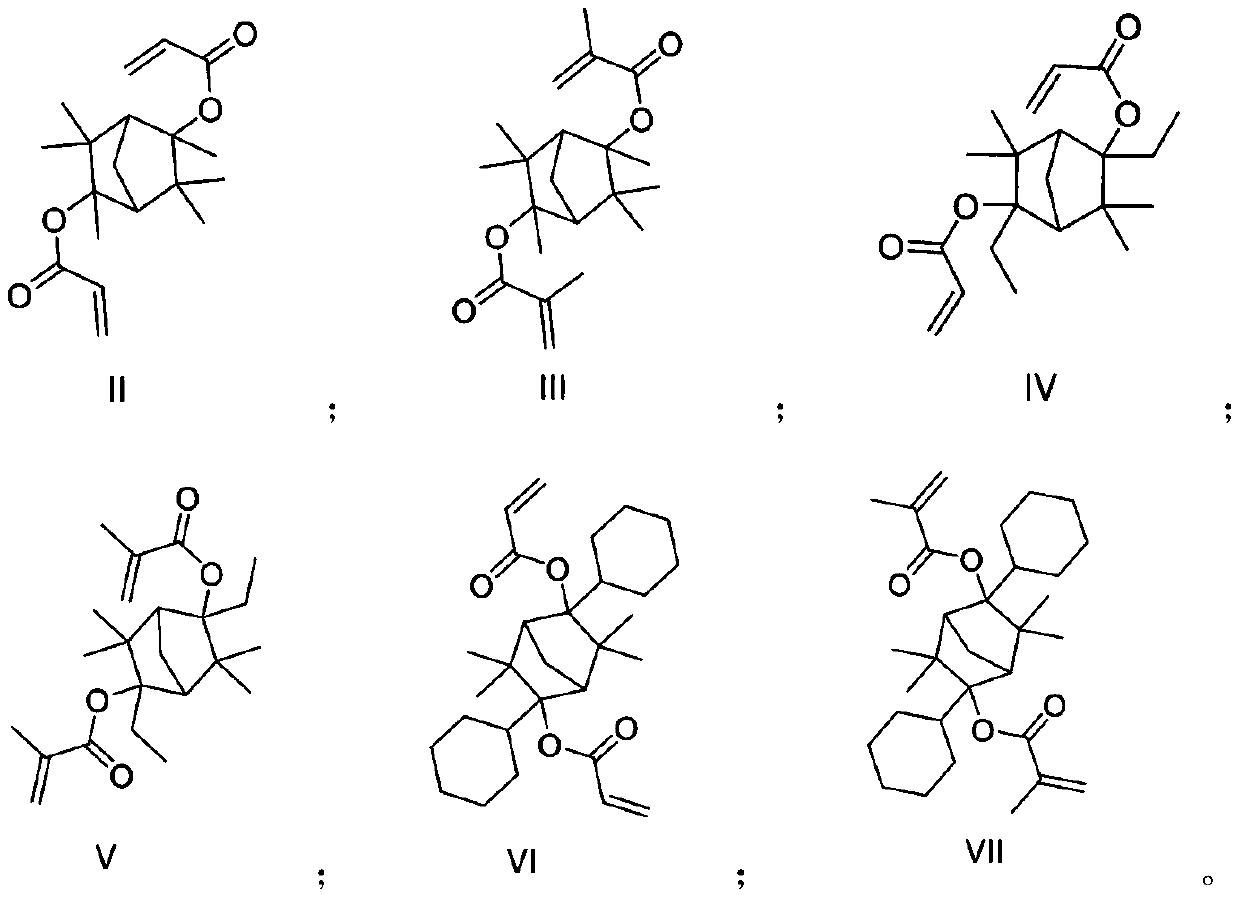

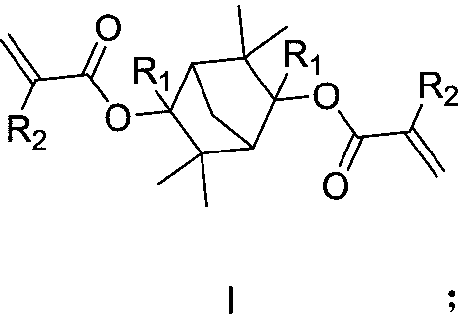

Embodiment 1

[0032] This embodiment provides a photoresist resin monomer, the reaction scheme of the synthesis method of the photoresist resin monomer is as follows:

[0033]

[0034] It specifically includes the following steps:

[0035] S1, preparation of methyl Grignard reagent: first add 2.7g of magnesium chips (111mmol) to 15ml of anhydrous ether, and add an iodine tablet to obtain a reaction solution; then, dissolve 10.6g of methyl bromide (112mmol) in 25mL Prepare a methyl bromide ether solution in diethyl ether; then, under the protection of nitrogen, first add 6mL methyl bromide ether solution to the above reaction solution. After 5 minutes, the reaction solution boils slightly, and the color of iodine disappears. Under stirring, continue to Add the remaining methyl bromide ethyl ether solution dropwise, and add 20 mL of diethyl ether, raise the temperature to keep boiling slightly, and reflux for half an hour to obtain the methyl Grignard reagent.

[0036] S2. Synthesis of in...

Embodiment 2

[0039] This embodiment provides a photoresist resin monomer, the reaction scheme of the synthesis method of the photoresist resin monomer is as follows:

[0040]

[0041] It specifically includes the following steps:

[0042] S1. According to the steps S1-S2 of the above-mentioned Example 1, 9.2 g of the intermediate (Formula 2-2, 43 mmol) was obtained, and the yield was 78.1%. .

[0043] S2. Dissolve 9.2g of the above intermediate in 120mL of anhydrous tetrahydrofuran, and add 17.6g of triethylamine (174mmol); then, cool to 0 degrees Celsius with ice water, and slowly drop into it under the protection of nitrogen Add a solution of methacryloyl chloride (9.1g, 87mmol) in anhydrous tetrahydrofuran (50mL) to obtain a reaction solution; after the reaction solution rises to room temperature and continues to react for 5 hours, the reaction solution is then concentrated under vacuum to remove the solvent, and add 50mL of ethyl acetate and 20mL of saturated aqueous sodium bicarb...

Embodiment 3

[0045] This embodiment provides a photoresist resin monomer, the reaction scheme of the synthesis method of the photoresist resin monomer is as follows:

[0046]

[0047] It specifically includes the following steps:

[0048] S1. Preparation of ethyl Grignard reagent: first add 2.7g of magnesium chips (111mmol) to 15ml of anhydrous ether, and add an iodine tablet to obtain a reaction solution; then, dissolve 12.1g of ethyl bromide (111mmol) in 25mL Prepare ethyl bromide ether solution in diethyl ether; then, under the protection of nitrogen, first add 6mL ethyl bromide ether solution to the above reaction solution. After 5 minutes, the reaction solution boils slightly, and the color of iodine disappears. Under stirring, continue to Add the remaining ethyl bromide ether solution dropwise, and add 20 mL of diethyl ether, raise the temperature to keep boiling slightly, and reflux for half an hour to obtain ethyl Grignard reagent.

[0049] S2. Synthesis of intermediates (Formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com