Atomic-scale monodispersed rhodium-based catalyst, preparation method thereof and application of atomic-scale monodispersed rhodium-based catalyst in preparation of methyl acetate through methanol gas-phase carbonylation

A monodisperse, atomic-level technology, applied in the fields of carbon monoxide or formate reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc. problems such as loss, to achieve the effect of high activity ratio homogeneous, reduced dosage and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation of embodiment 1 catalyst sample

[0068] Rhodium source and additive element M source are dissolved in the deionized water of 15ml, obtain mixed solution, then 10.0g activated carbon (coconut shell charcoal, specific surface area is 1000m 2 / g, with an average particle size of 50um) immersed in the mixed solution. Evaporate the solvent in a water bath at 90°C, dry in an oven at 120°C for 8 hours, and roast at 300°C under nitrogen protection for 4 hours to obtain the precursor. The precursor is placed in a mixed atmosphere of carbon monoxide and halogenated alkanes for post-treatment to obtain the atomic-level monodisperse rhodium-based catalyst.

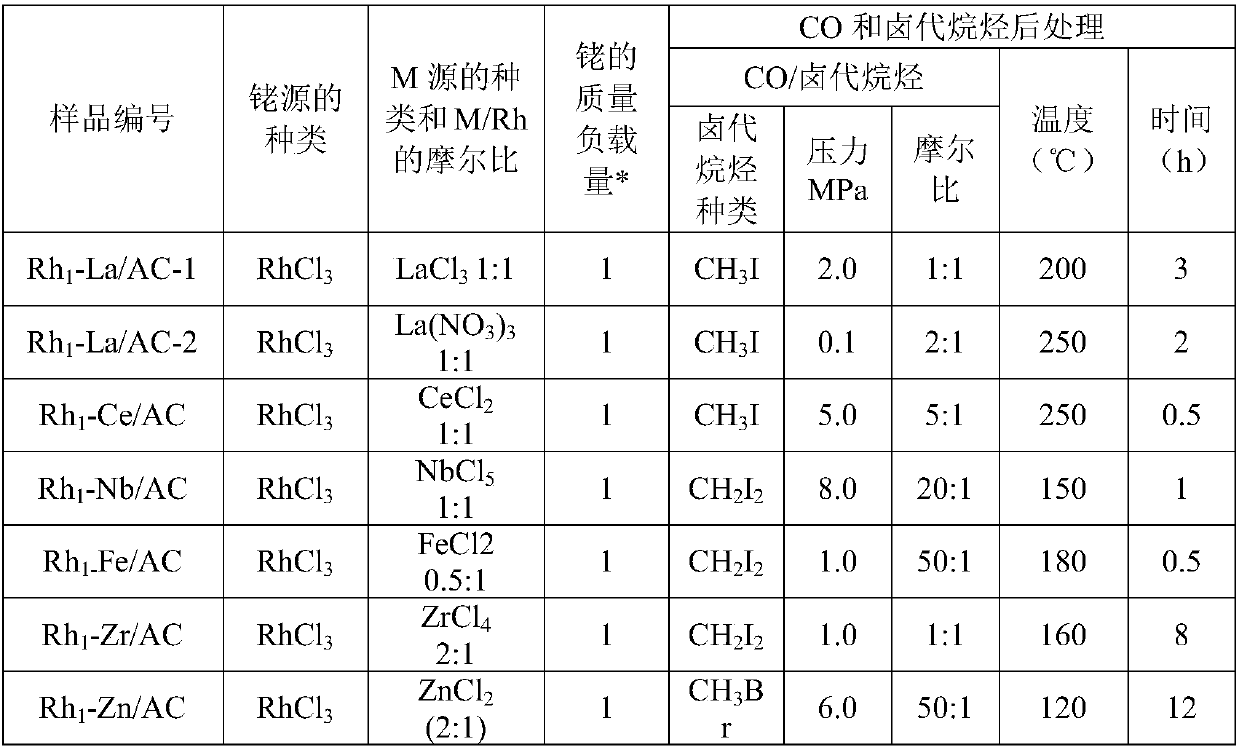

[0069] The relationship between the sample numbers of the obtained samples and the preparation conditions is shown in Table 1.

[0070] Table 1

[0071]

[0072]

[0073] *: Calculated by mass percentage of rhodium element in the catalyst.

Embodiment 2

[0074] The characterization of embodiment 2 catalyst sample

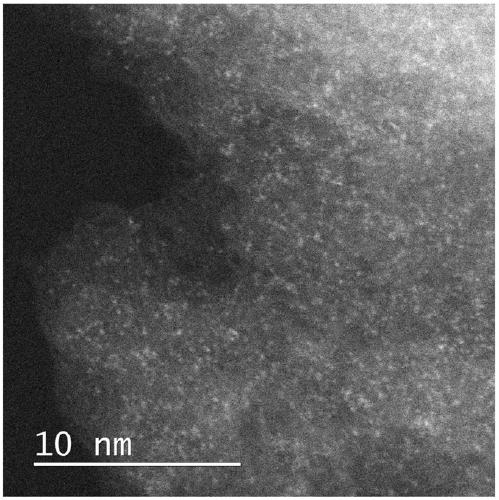

[0075] The samples obtained in Example 1 were characterized by transmission electron microscopy and spherical aberration electron microscopy, and the results showed that in the samples prepared in Example 1, rhodium was dispersed in the rhodium-based catalyst in the form of mononuclear complexes .

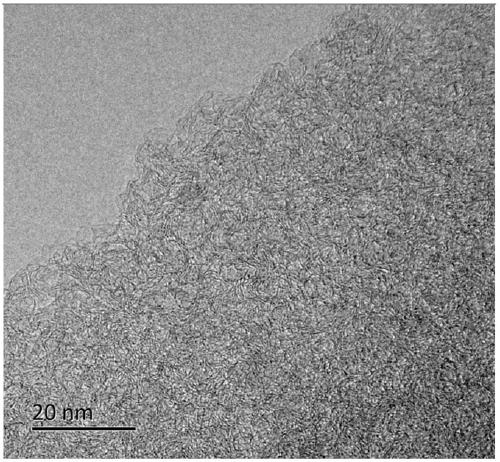

[0076] Among them, the sample Rh 1 -La / AC-1 is a typical representative, and its ordinary electron microscope photos are as follows figure 1 As shown, its spherical aberration electron microscope photo is shown as figure 2 shown. From figure 1 It can be found that: under the macroscopic scale with the highest resolution of 50nm in the ordinary electron microscope, the supported nano-metal particles cannot be seen in the carrier activated carbon; in the further spherical aberration electron microscope photos, the metal catalyst dispersed at the single atomic level can be clearly seen.

[0077] The test results of th...

Embodiment 3

[0078] Embodiment 3 methanol vapor phase carbonylation prepares methyl acetate reaction

[0079] The catalyst (0.3 g) obtained in Example 1, with an average particle size of 500 μm, was placed in a fixed-bed quartz tube reactor, and 20-40 mesh quartz sand was loaded at both ends. Then the temperature was raised from room temperature to 240°C at a rate of 5°C / min, and H 2 , CO, methanol, and methyl iodide (molar ratio CO / H 2 =10, molar ratio CO / CH 3 OH=1, mass ratio CH 3 OH / CH 3 I=7 / 3), reaction pressure 1.7MPa, methanol liquid hourly volume space velocity 12h -1 The reaction was stable for 24 hours under certain conditions, and the conversion rate of methanol and the selectivity of methyl acetate were analyzed and calculated online. The results are shown in Table 2.

[0080] Table 2

[0081] catalyst Methanol conversion (%) Methyl acetate selectivity*(%) Rh 1 -La / AC-1

[0082] *Based on methanol converted, other products are mainly acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com