EC-free lithium ion battery electrolyte suitable for high nickel-silicon carbon system

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of high-voltage instability of ethylene carbonate, small SEI film resistance, thickness expansion and small increase in internal resistance, etc., to achieve excellent Li+ conductivity and optimize battery life. Chemical properties, effectiveness in mitigating incompatibility issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

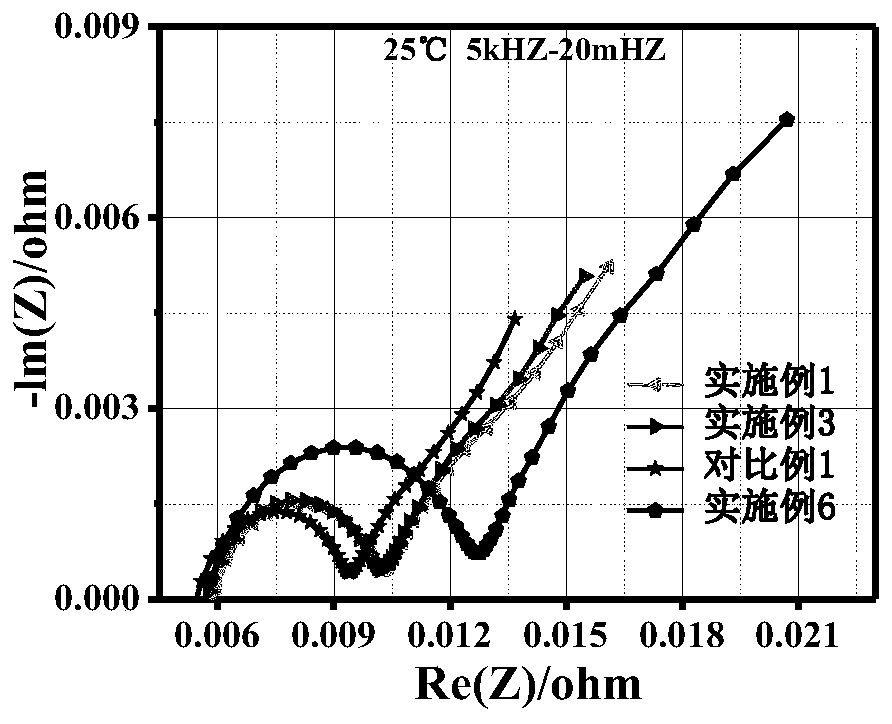

[0027] See Figure 1 to Figure 3 , The present invention provides a technical solution: an electrolyte suitable for high nickel-silicon-carbon system EC-free lithium ion batteries, the preparation of the electrolyte: in a drying room with a dew point of -50 ℃, propylene carbonate (PC) , Fluorinated ethylene carbonate (FEC), dimethyl carbonate and diethyl carbonate (DEC) with a ratio of 2.5:1:4.5:2 for mixing, and then slowly adding 13.0wt% of lithium hexafluorophosphate based on the total weight of the electrolyte to the mixed solution (LiPF 6 ), 1.0wt% of lithium difluorophosphate (LiPO 2 F 2 ) And 0.5wt% of PST based on the total weight of the electrolyte, and finally add 0.3wt% based on the total weight of the electrolyte of compound A with the structure shown in formula I (see Table 1 for the specific selection of compound A), 10.0wt% FEC and 0.3 wt% TAP, after stirring uniformly, the lithium ion battery electrolyte of Example 1 was obtained.

[0028] Preparation of soft-pac...

Embodiment 2 to Embodiment 6

[0029] Example 2 to Example 6 and Comparative Example 1 to Comparative Example 4:

[0030] In Example 2 to Example 6 and Comparative Example 1 to Comparative Example 4, except that the composition ratio of each component of the electrolyte is the additive shown in Table 1, the others are the same as in Example 1.

[0031] Table 1: The composition ratio of each component of the electrolyte of Example 1-6 and Comparative Example 1-4

[0032]

[0033]

[0034]

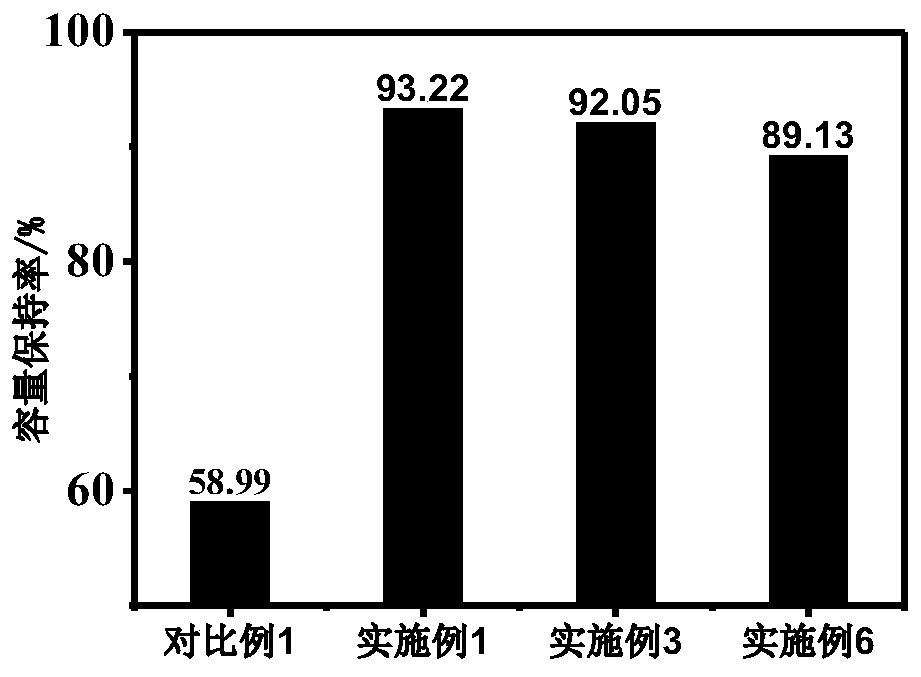

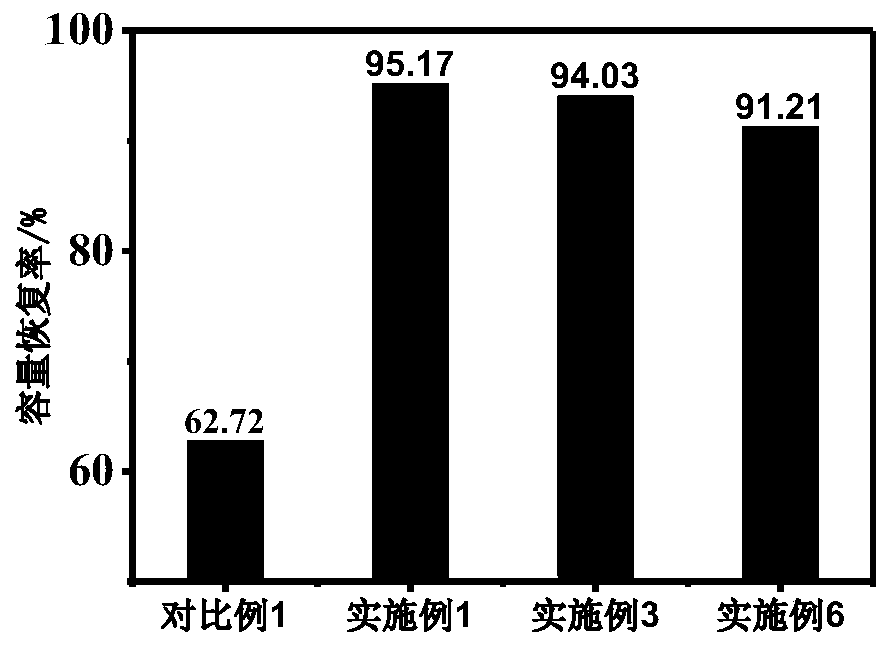

[0035] Performance Testing

[0036] Perform performance tests on the full batteries prepared in Example 2 to Example 6 and Comparative Example 1 to Comparative Example 3:

[0037] (1) Normal temperature cycle performance test: At 25℃, charge the divided battery to 4.35V according to 1C constant current and constant voltage, cut-off current of 0.05C, and then discharge to 2.7V according to 1C constant current, according to this cycle, charge / Calculate the capacity retention rate of the 1000th cycle after discharge for 1000 cycles,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com