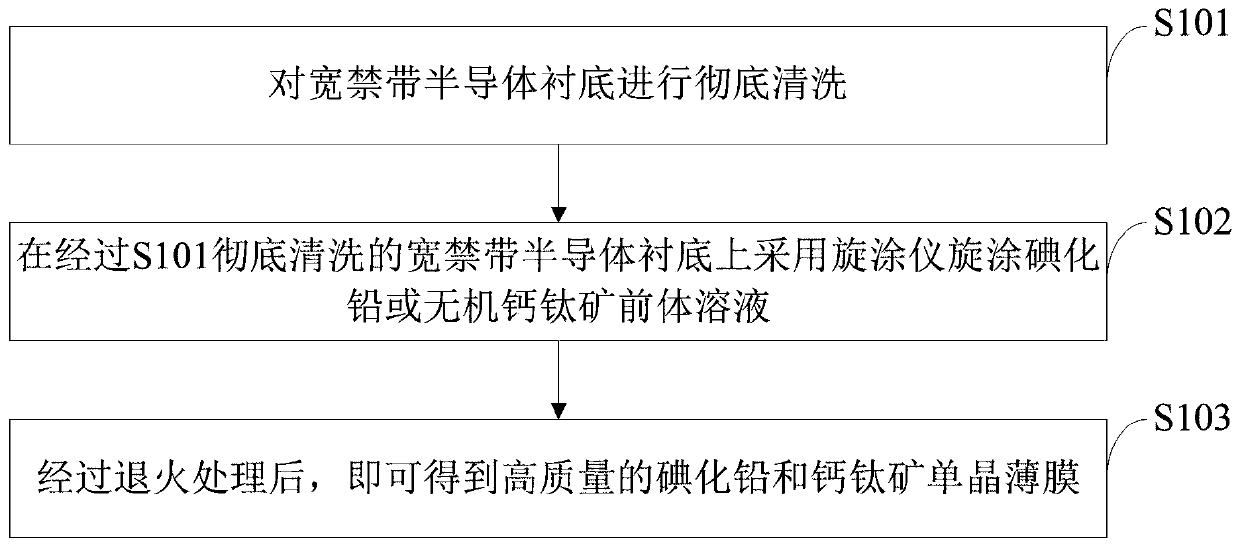

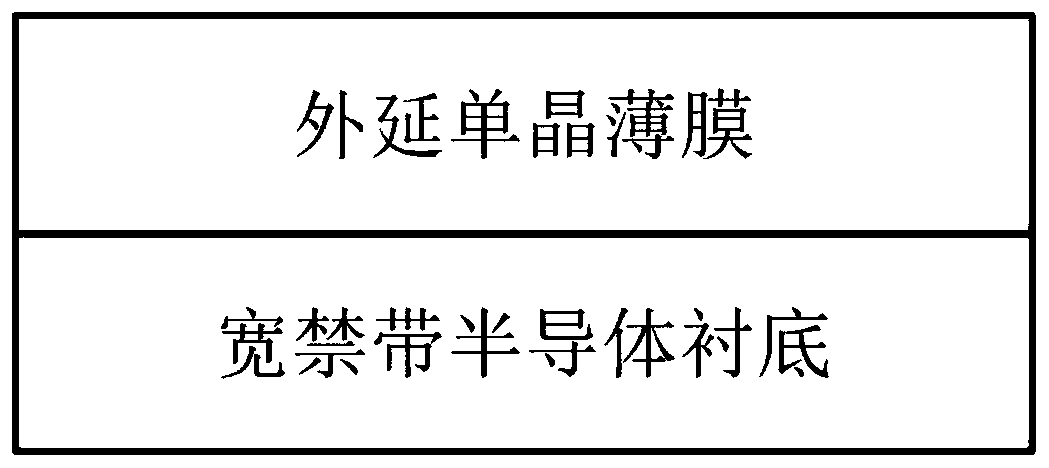

Growth method for spin-coating single crystal on wide bandgap semiconductor substrate

A wide-bandgap semiconductor and growth method technology, which is applied to the growth field of spin-coated single crystals on wide-bandgap semiconductor substrates, can solve the problems of complex processes, harsh growth conditions, and expensive equipment, and achieves high crystal quality and defects. Density reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

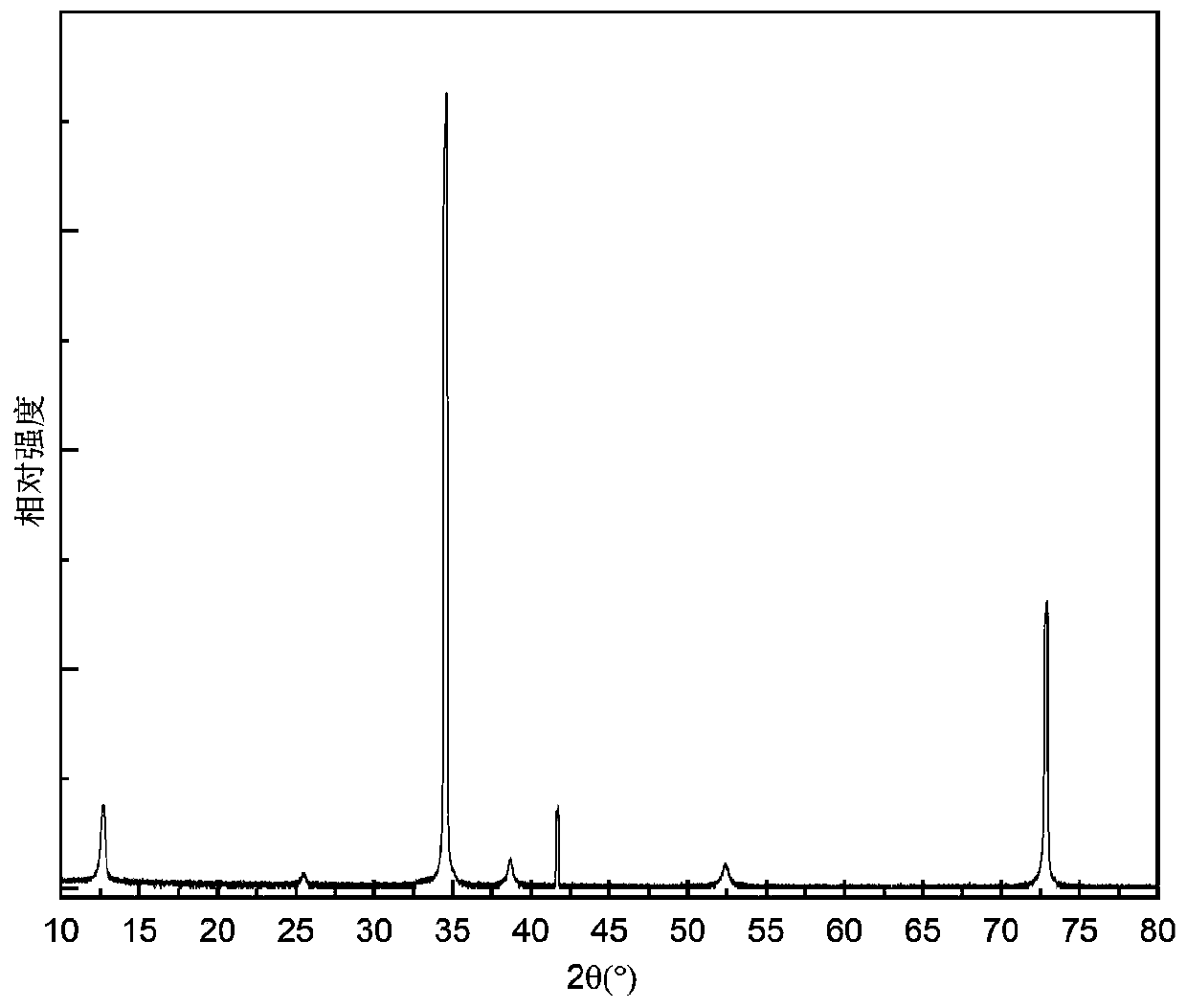

[0057] see image 3 The XRD diffraction pattern of the lead iodide film, the lead iodide material was grown on the thoroughly cleaned gallium nitride substrate by the spin coating process, and a high-quality single-oriented epitaxial lead iodide single crystal film was obtained, and the lead iodide was only Clusters of {001} facets appear. Wherein, the substrate may be any one or a composite substrate formed of aluminum gallium nitride, indium gallium nitride, gallium nitride, aluminum nitride or silicon carbide substrates. The solute of the lead iodide precursor solution is lead iodide powder with a purity greater than 99.9%, and the solvent is a mixed solution of N,N-dimethylformamide and dimethyl sulfoxide, wherein N,N-dimethylformamide The ratio to dimethyl sulfoxide is about 4:1. The concentration of the lead iodide precursor solution is 0.5 moles per liter to 2 moles per liter. The lead iodide precursor solution was stirred at about 70° C. for 2 hours on a heated stir...

Embodiment 2

[0059] see Figure 4 XRD diffraction pattern of perovskite, high-quality epitaxial perovskite CsPbBrI was obtained by growing perovskite material on single crystal silicon substrate by spin-coating process 2 For single crystal thin films, only (200) crystal planes appear in perovskite. Wherein, the substrate may be any one or a composite substrate formed of aluminum gallium nitride, indium gallium nitride, gallium nitride, aluminum nitride or silicon carbide substrates. The solute of the precursor solution of the perovskite solution is lead iodide powder, lead bromide powder, cesium iodide powder and cesium bromide powder, and the solvent is N,N-dimethylformamide and dimethyl sulfoxide A mixed solution, wherein the ratio of N,N-dimethylformamide to dimethyl sulfoxide is 1:1. The concentration of the perovskite solution is 0.3 to 0.5 moles per liter. The perovskite solution precursor solution was stirred at about 70 °C for 2 hours on a heated stirring table to obtain a clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com