Multifunctional sustained-release agent for industrial circulating water system and preparation method thereof

An industrial circulating water and multi-functional technology, which is applied in chemical instruments and methods, natural water treatment, non-polluted water treatment, etc., can solve the problems of shortening the service life of equipment, single function of slow-release agent, and reducing thermal conductivity, etc., to reduce The risk of shutdown and production stoppage, the effect of stabilizing permeability and preventing penetration, and stabilizing the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

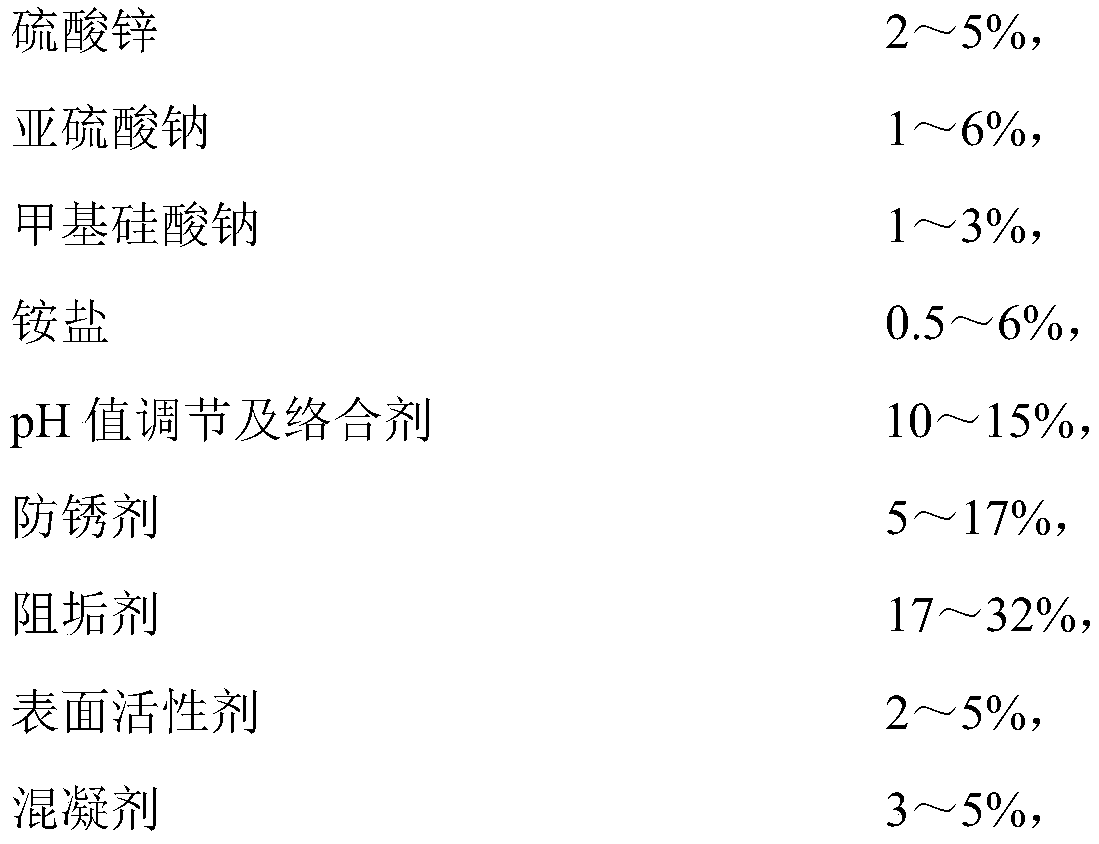

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 100kg of deionized water to a 50-liter reactor;

[0028] (2) Under stirring conditions, add 4 kg of zinc sulfate, 2 kg of sodium sulfite, 1.5 kg of sodium methyl silicate, 2 kg of ammonium chloride, and 3 kg of polyferric sulfate. After mixing evenly, add 10 kg of oxalic acid, benzotri Azole 15 kg, ethylenediamine tetramethylene phosphonic acid 17.5 kg, sodium dodecylbenzene sulfonate 3 kg, borax 23 kg, fully dissolved;

[0029] (3) Then add 14kg of sodium citrate and 5kg of sodium edetate, stir well, adjust the pH to about 5, and let it stand for 4 hours before use.

Embodiment 2

[0031] (1) Add 100kg of deionized water to a 50-liter reactor;

[0032] (2) Add 3kg of zinc sulfate, 1.5kg of sodium sulfite, 2.5kg of ammonium chloride, 2kg of sodium methyl silicate, and 3kg of polyaluminum chloride under stirring conditions. After mixing evenly, add 5kg of oxalic acid six times Methyltetraammonium 5kg, benzotriazole 14kg, ethylenediamine tetramethylene phosphonic acid 20kg, sodium lauryl sulfate 1kg, borax 22kg, fully dissolved;

[0033] (3) Then add 15kg of sodium citrate and 5kg of phosphoric acid, stir well, adjust the pH to about 3.5, and let it stand for 3 hours before use.

Embodiment 3

[0035] (1) Add 100kg of deionized water to a 50-liter reactor;

[0036] (2) Under stirring conditions, first add 2 kg of zinc sulfate, 5 kg of sodium sulfite, 1 kg of ammonium chloride, 3 kg of sodium methyl silicate, and 3 kg of alum. After mixing evenly, add 4 kg of hexamethylene tetraammonium, Benzotriazole 18kg, ethylenediamine tetramethylene phosphonic acid 19kg, sodium lauryl sulfate 1kg, sodium dodecylbenzenesulfonate 1kg, borax 20.5kg, ethylene glycol 7.5kg, make it fully dissolved;

[0037] (3) Then add 10kg of sodium citrate and 5kg of sodium dihydrogen phosphate, stir well, adjust the pH to about 4.5, and then use it after standing for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com