Preparation method of functional edible oil

A kind of edible oil and functional technology, which is applied in the direction of fat oil/fat refining, fat oil/fat production, and preservation of fat substances with additives, etc. It can solve the problems of extensive processing and production technology, complex triglyceride components, and high oil peroxide value. , to achieve the effect of reducing the extraction time, reducing the unpleasant smell and increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

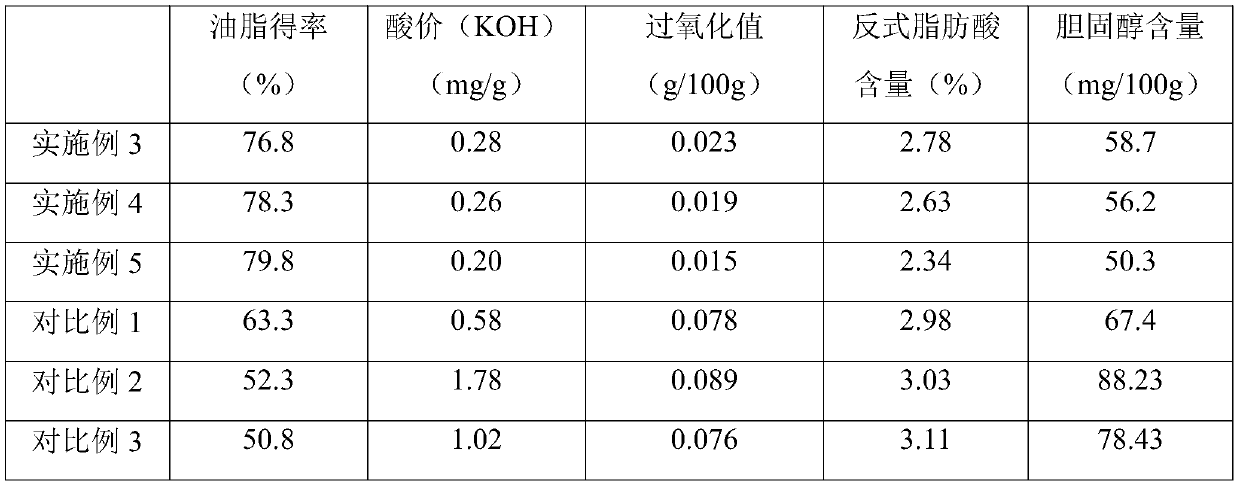

Examples

Embodiment 1

[0032] Preparation of Lemon Seed / Garlic Compound Oil:

[0033] (1) Cleaning, removing impurities and drying the lemon seeds with full fresh grains, crushing the lemon seeds into powder after shelling, and pressing them physically at a low temperature of 40-50°C to obtain lemon seed oil;

[0034] (2) Clean and remove impurities from fresh garlic, slice it, freeze-dry it, grind it into 80-100 mesh powder, soak 1kg of garlic powder in 10L lemon seed oil, stir and filter it through a plate and frame filter to obtain lemon seed / garlic compound oil; wherein, the stirring treatment conditions are: stirring temperature 5-10°C; stirring time 30-45min; stirring speed 800-1000r / min;

Embodiment 2

[0036] Preparation of enzyme-loaded lotus leaves:

[0037] Get the fresh lotus leaf after washing and removing impurities, cut it into 3cm×3cm flakes and place it in a freeze dryer to dry, then soak in the sodium alginate aqueous solution of bromelain (the content of bromelain is 2wt%, the content of sodium alginate 0.5wt%), after the ultrasonic dispersion treatment, take out the freeze-drying, and repeat the immersion and freezing treatment for 2-3 times continuously to obtain the enzyme-loaded lotus leaf A;

[0038]After fresh lotus leaves are cleaned and removed, they are cut into 6cm×6cm flakes and placed in a freeze dryer, soaked in an aqueous sodium alginate solution of bromelain (the content of bromelain is 4wt%, and the content of sodium alginate is 1wt%) %), after ultrasonic dispersion treatment, take out freeze-drying, and obtain enzyme-loaded lotus leaf B after continuous repeated soaking and freezing treatment for 2-3 times;

Embodiment 3

[0040] The preparation of functional edible oil specifically comprises the following steps:

[0041] (1) Raw material processing: take fresh peanuts and shell them to obtain fresh peanut seeds, grind 1kg of peanut seeds to obtain peanut pulp; take 10kg of beef fat tissue, chop and stir to obtain granular fat, stir and mix with peanut pulp to obtain a mixture slurry;

[0042] (2) Ultrasonic immersion: After the mixed slurry is decocted in water; soaked in the mixed emulsion of 1 times the weight of the mixed slurry, the supernatant liquid layer A and the emulsified layer are obtained after ultrasonic and microwave synergistic treatment; the mixed emulsion is made of lemon seed / Garlic compound oil, cysteine hydrochloride, fatty acid sucrose ester are dispersed in 50% edible alcohol and obtain, wherein, the mass percentage content of lemon seed / garlic compound oil is 5%, cysteine hydrochloride The mass percentage content is 0.05%, the mass percentage content of fatty acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap