Bright black nickel plating electroplate solution and preparation method and application thereof

An electroplating solution and bright technology, applied in the field of nickel electroplating, can solve the problem of unclear specific purpose, and achieve the effect of strong wear resistance, tight bonding and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

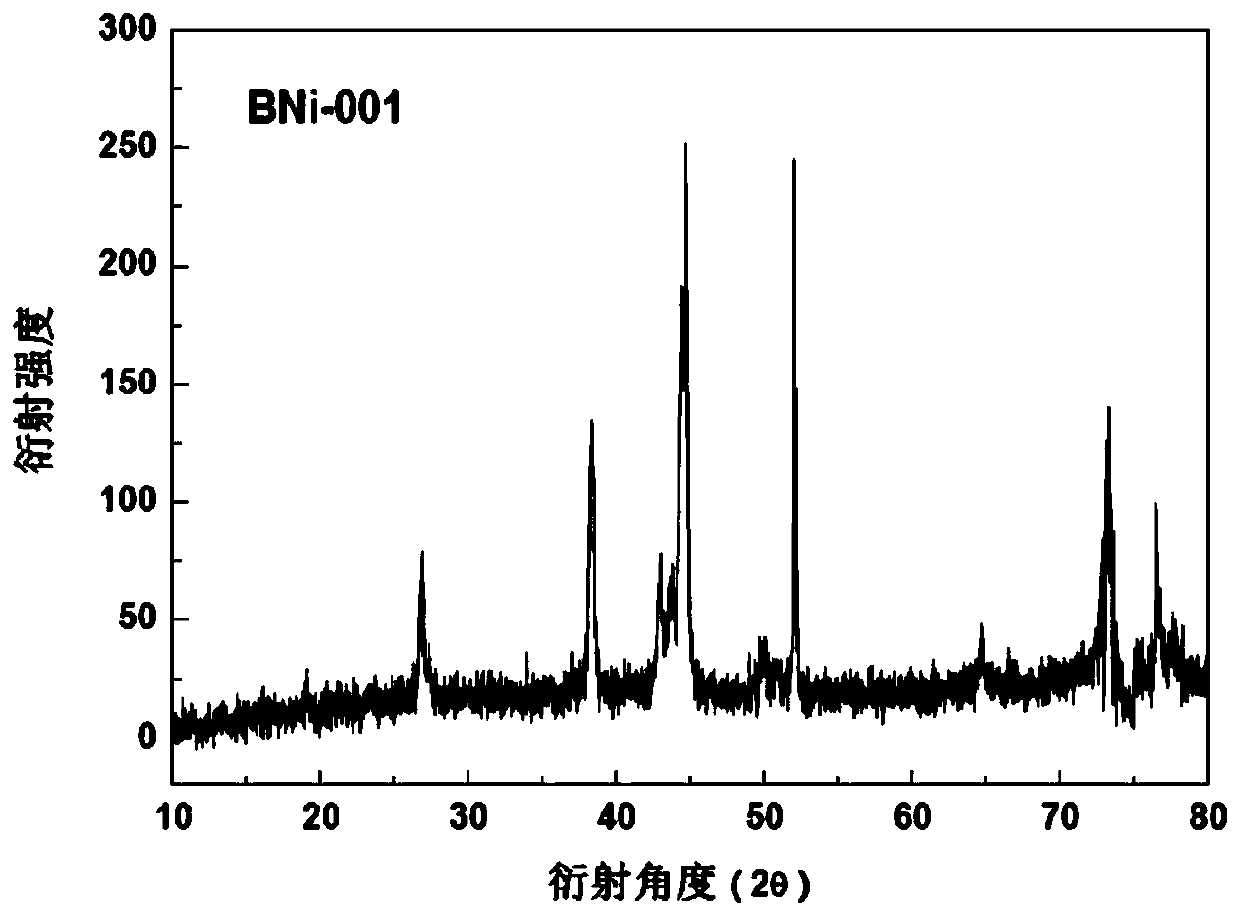

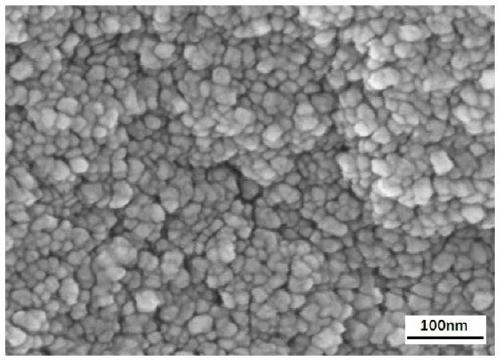

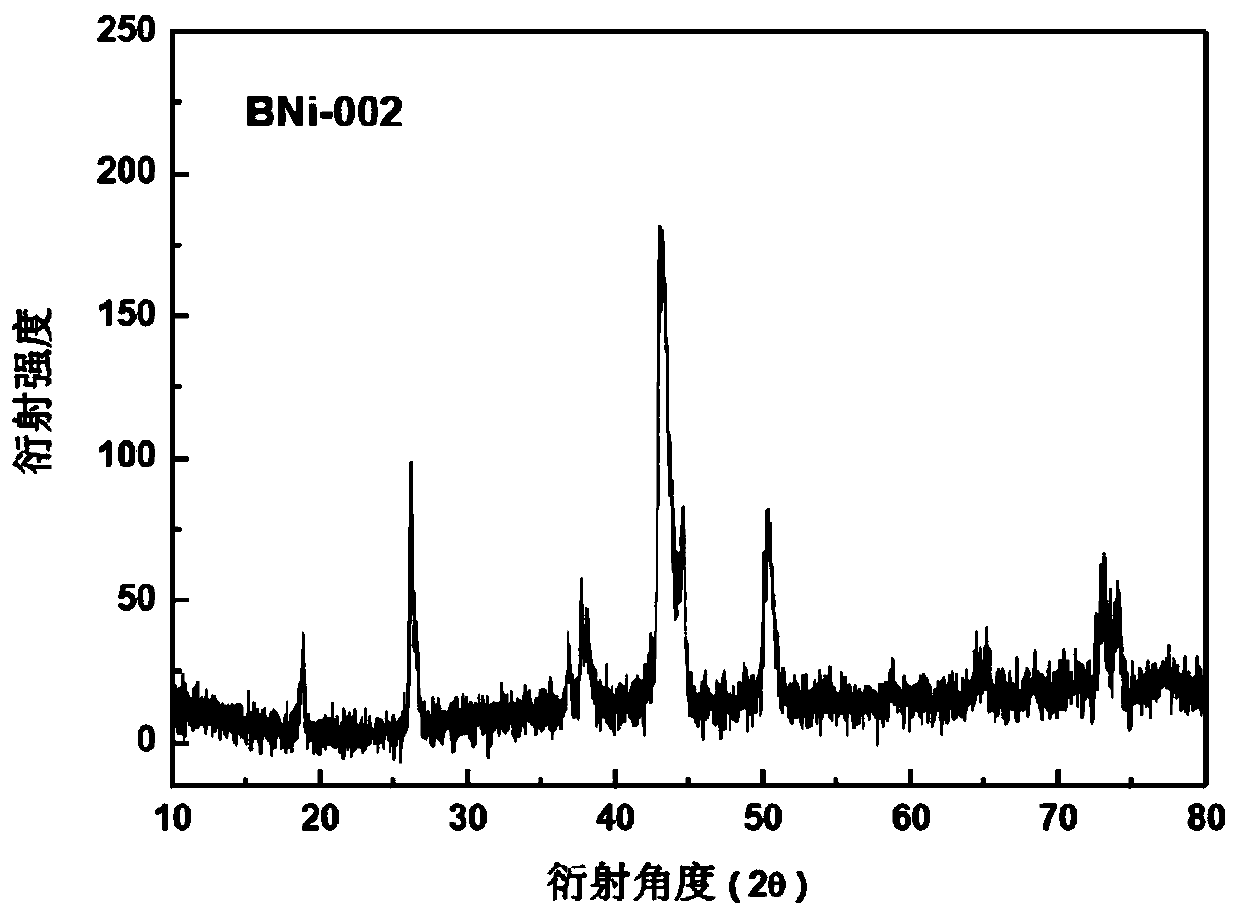

Image

Examples

Embodiment 1

[0054] A preparation method of a novel bright black nickel electroplating solution, the steps are:

[0055] In the first step, under the condition of 35°C, 25 g of HINCPH and CTN mixture mixed in equal mass ratio were dissolved in 1 L of additive A ammonium sulfate solution with a concentration of 20 g / L;

[0056] In the second step, 15g of nickel sulfate, 10g of nickel chloride, 2.5g of iron sulfate, 2.5g of zinc sulfate, 2.5g of copper sulfate, 1.5g of magnesium sulfate, 1.5g of manganese sulfate, and 0.5g of nitric acid were added successively to the solution obtained in the first step. Silver, 15g thioacetamide, stirred until various salts were completely dissolved;

[0057] In the third step, in the solution obtained in the second step, add 25g additive B water-soluble chitosan oligosaccharide, ethylenediaminetetraacetic acid (EDTA) and other quality mixtures, stir until additive B dissolves completely;

[0058] In the fourth step, add 15g of additive C oxalic acid and 5...

Embodiment 2

[0061] A preparation method of a novel bright black nickel electroplating solution, the steps are:

[0062]In the first step, under the condition of 40°C, 35 g of HINCPH and CTN mixture mixed in equal mass ratio were dissolved in 1 L of additive A ammonium dihydrogen phosphate solution with a concentration of 35 g / L;

[0063] In the second step, add 25g of nickel sulfate, 15g of nickel chloride, 4.5g of iron sulfate, 4.5g of zinc sulfate, 4.5g of copper sulfate, 2.5g of magnesium sulfate, 2.5g of manganese sulfate, and 1.0g of nitric acid in the solution obtained in the first step. Silver, 20g thioacetamide, stirred until various salts were completely dissolved;

[0064] In the third step, in the solution obtained in the second step, add 35g additive B water-soluble chitosan oligosaccharide, ethylenediaminetetraacetic acid (EDTA) and other quality mixtures, stir until B is completely dissolved;

[0065] The 4th step, in the solution gained in the 4th step, add 20g additive C ...

Embodiment 3

[0068] A preparation method of a novel bright black nickel electroplating solution, the steps are:

[0069] In the first step, at 45°C, 45 g of HINCPH and CTN mixture mixed in equal mass ratio was dissolved in 1 L of additive A ammonium sulfate solution with a concentration of 35 g / L;

[0070] In the second step, 25g of nickel sulfate, 20g of nickel chloride, 4.5g of iron sulfate, 4.5g of zinc sulfate, 4.5g of copper sulfate, 3.5g of magnesium sulfate, 3.5g of manganese sulfate, 1.5g of Silver nitrate, 25g thioacetamide, stirred until the various salts are completely dissolved;

[0071] In the third step, in the solution obtained in the second step, add 45g additive B water-soluble chitosan oligosaccharide, ethylenediaminetetraacetic acid (EDTA) and other quality mixtures, and stir until B is completely dissolved;

[0072] The fourth step, to the solution obtained in the fourth step, add 25g additive C oxalic acid, malonic acid, succinic acid, citric acid, one or two or three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com