Lithium-rich manganese-based lithium ion battery high-voltage electrolyte additive, electrolyte, lithium battery and preparation method of lithium battery

An electrolyte additive, lithium-rich manganese-based lithium technology, applied in lithium-rich manganese-based lithium-ion battery high-voltage electrolyte additive, electrolyte, lithium battery and its preparation field, can solve the irreversible capacity fading of lithium-rich manganese-based positive electrode materials, Interfacial impedance increase, battery performance deterioration and other problems, to avoid the effect of battery performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example provides a high-voltage electrolyte additive for lithium-rich manganese-based lithium-ion batteries. The raw materials for the preparation include fluoroethylene carbonate, 1,3-propane sultone, phenylvinyl sulfone and boric acid tris(2,2,2 -trifluoroethyl) ester.

[0042] Among them, the mass ratio of fluoroethylene carbonate, 1,3-propane sultone, phenylvinyl sulfone and tris(2,2,2-trifluoroethyl) borate is (1~5): (0.5 ~2): (0.5~1.5): (0.1~1), preferably 8:2:2:1.

Embodiment 2

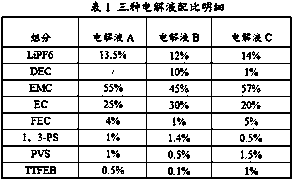

[0044] This example provides a high-voltage electrolyte solution for a lithium-rich manganese-based lithium-ion battery, which contains the electrolyte additive, lithium salt and solvent of Example 1.

[0045] Among them, the proportion of the electrolyte additive in the electrolyte is 3-10 wt%. Specifically, in the electrolyte, the proportion of fluoroethylene carbonate is 1-5 wt%. The proportion of 1,3-propane sultone is 0.5~2 wt%. The proportion of PVS is 0.5~1.5wt%. The proportion of TTFEB is 0.1~1 wt%.

[0046]The proportion of lithium salt in the electrolyte is 12-14 wt%. The lithium salt is lithium hexafluorophosphate. The concentration of lithium hexafluorophosphate is preferably 1.2 mol / L.

[0047] The solvent accounts for 60-90 wt% in the electrolyte. The solvent is a mixture of ethyl methyl carbonate and ethylene carbonate, and the mass ratio is preferably 11:5. Specifically, the proportion of ethyl methyl carbonate in the electrolyte is 45-60 wt%. The propo...

Embodiment 3

[0049] This example provides a method for preparing a high-voltage electrolyte for lithium-rich manganese-based lithium-ion batteries. The preparation method is as follows: adding lithium salt and electrolyte additives to the solvent in sequence.

[0050] When the lithium salt is added to the solvent, the ambient temperature is -5°C~5°C.

[0051] The preparation method of lithium-rich manganese-based lithium-ion battery high-voltage electrolyte, the specific process is: purification → mixing → deployment → filling.

[0052] Wherein, the purification process is to purify the solvent, and use the adsorption of molecular sieves to control the moisture content of the solvent below 5 ppm. In the mixing process, the two solvents are mixed at a pressure of 0.02-0.08 MPa, and the water content of the mixed solvent is kept below 6 ppm by keeping the airtightness of the reaction vessel. The blending process is to add lithium salt and additives to the solvent, and the lithium salt is fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com