Alkali metal doped garnet type lithium lanthanum zirconium oxide powder and preparation method thereof

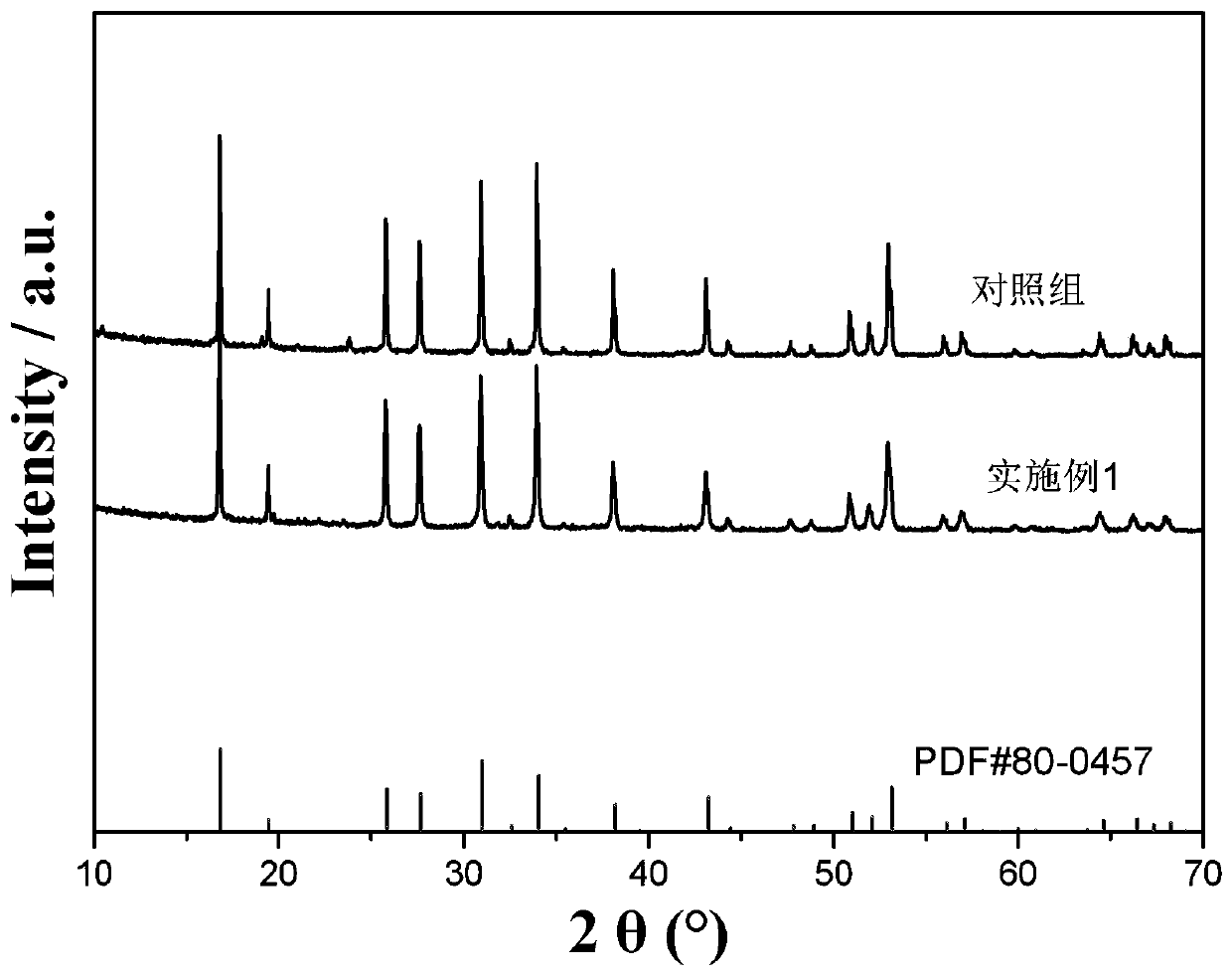

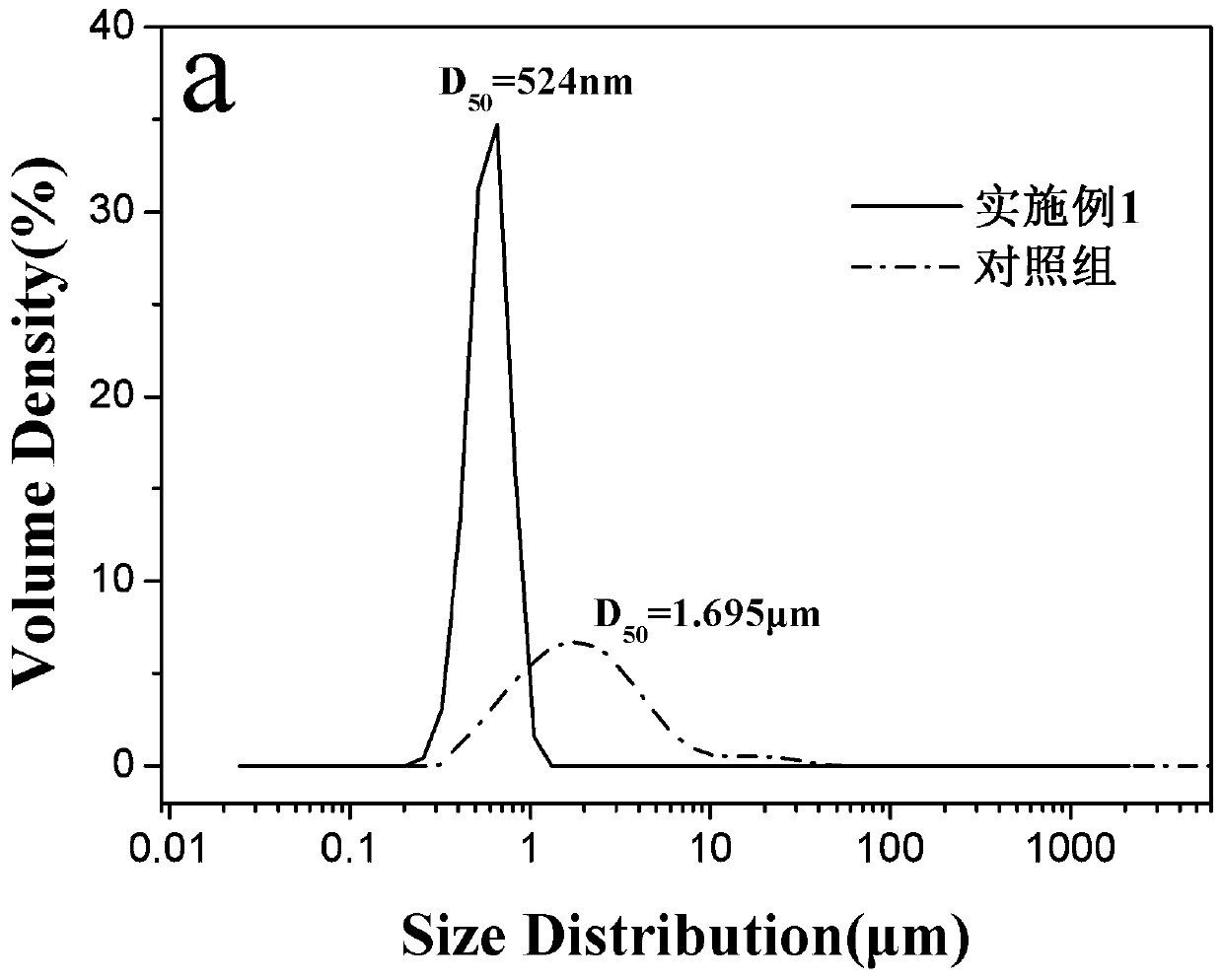

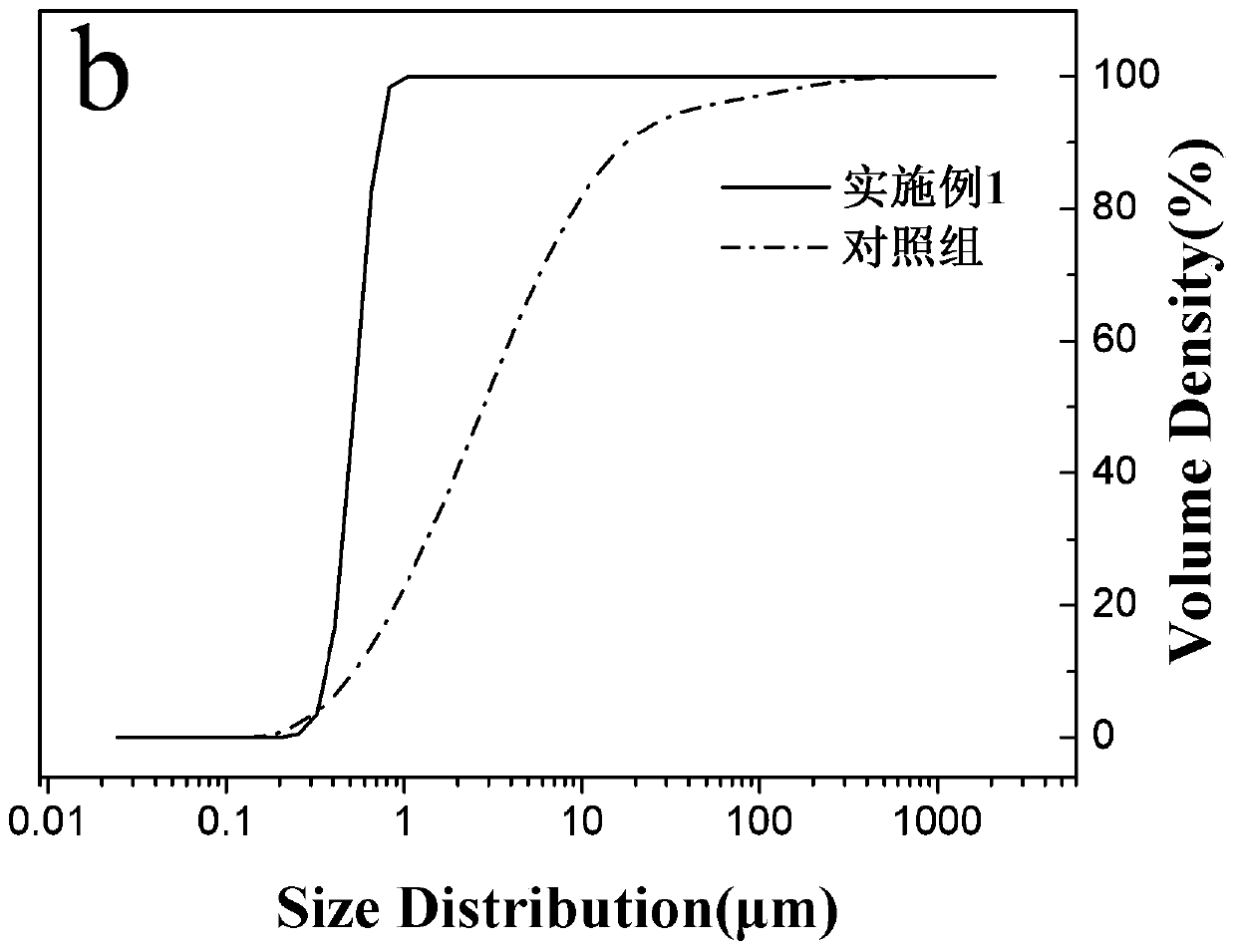

A technology of lithium lanthanum zirconium oxide and garnet type, which is applied in the field of alkali metal doped garnet type lithium lanthanum zirconium oxide powder and its preparation, can solve the unfavorable application of flexible composite solid electrolyte, unsatisfactory particle size of powder materials, particle size Uneven distribution and other problems, to achieve the effect of easy industrial production, small grain size and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of alkali metal doped garnet type lithium lanthanum zirconium oxide powder (Li 7.2 La 2.9 Rb 0.1 Zr 2 o 12 ), the specific preparation method is as follows:

[0040] Dissolve 0.36mol of lithium carbonate, 0.29mol of lanthanum nitrate, and 0.2mol of zirconium hydroxide in 100mL of deionized water, and stir until completely dissolved to obtain solution A; dissolve 0.01mol of rubidium chloride in 100mL of deionized water to obtain solution B; Add cyclohexane, 20mL cetyltrimethylammonium bromide, and 80mL n-butanol into a beaker and stir evenly to obtain solution C. Divide solution C into two equal parts of 150mL each, and record them as C 1 、C 2; Add solution A dropwise to solution C under ultrasonic vibration 1 , the dropping time is 10 minutes to obtain emulsion D, and solution B is added dropwise to solution C under the condition of ultrasonic vibration 2 Emulsion E was obtained in , and the dropping time was 10 minutes. Mix solution D and solution E evenl...

Embodiment 2

[0044] A kind of alkali metal doped garnet type lithium lanthanum zirconium oxide powder (chemical formula Li 7.2 La 2.9 K 0.1 Zr 2 o 12 ), the specific preparation method is as follows:

[0045] Dissolve 0.72mol lithium hydroxide, 0.29mol lanthanum hydroxide, and 0.2mol zirconium hydroxide in 100mL deionized water, stir until completely dissolved to obtain solution A; dissolve 0.005mol potassium carbonate in 100mL deionized water to obtain solution B; Add 200mL of cyclohexane, 20mL of cetyltrimethylammonium chloride, and 80mL of n-butanol into a beaker and stir evenly to obtain solution C. Divide solution C into two equal parts of 150mL each, and record them as C 1 、C 2 ; Add solution A dropwise to solution C under ultrasonic vibration 1 , the dropping time is 15 minutes to obtain emulsion D, and solution B is added dropwise to solution C under the condition of ultrasonic vibration 2 Emulsion E was obtained in , the dropping time was 15 minutes, and the solution D and ...

Embodiment 3

[0047] A kind of alkali metal doped garnet type lithium lanthanum zirconium oxide powder (chemical formula Li 7.2 La 2.9 Cs 0.1 Zr 2 o 12 ), the specific preparation method is as follows:

[0048] Dissolve 0.72mol of lithium nitrate, 0.29mol of lanthanum nitrate, and 0.2mol of zirconium oxynitrate in 100mL of deionized water, and stir until completely dissolved to obtain solution A; dissolve 0.01mol of cesium nitrate in 100mL of deionized water to obtain solution B; Add hexane, 20mL cetyldimethylammonium oxide, and 80mL n-butanol into a beaker and stir evenly to obtain solution C. Divide solution C into two equal parts of 150mL each, and record them as C 1 、C 2 ; Add solution A dropwise to solution C under ultrasonic vibration 1 , the dropping time is 20 minutes to obtain emulsion D, and solution B is added dropwise to solution C under the condition of ultrasonic vibration 2 Emulsion E was obtained in , the dropping time was 20 minutes, and solution D and solution E wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com