Preparation and application of nickel-based three-dimensional graphene/manganese dioxide composite material

A technology of manganese dioxide and composite materials, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve the problem of not completely solving the limitations of graphene and manganese dioxide, large contact resistance of electrodes, and difficulty in scaling In order to achieve the effect of improving electrochemical characteristics, improving contact points, and avoiding the increase of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

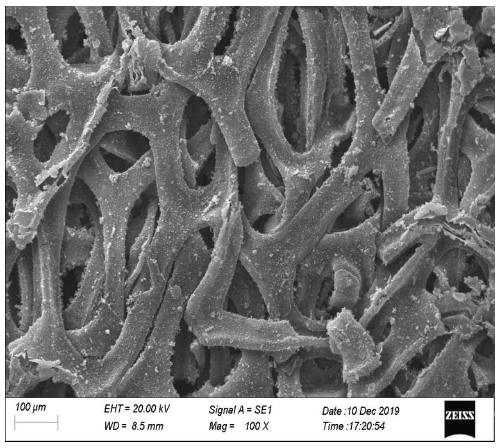

[0045] A preparation method of a nickel-based three-dimensional graphene / manganese dioxide composite material, comprising the steps of:

[0046] 1) Dissolve sucrose in deionized water, prepare a sucrose solution with a concentration of 0.5mol / L and place it in a quartz boat, use foamed nickel as a base to immerse in the sucrose solution, and transfer the entire quartz boat into a chemical vapor deposition furnace , in a nitrogen atmosphere, chemical vapor deposition at 700 ° C for 1 h, and carbonization of sucrose in a high-temperature inert gas atmosphere, so that graphene carbon materials can be grown on the nickel-based surface in situ, that is, the nickel-based three-dimensional interconnected network structure graphene is obtained ;

[0047] 2) Use nickel-based three-dimensional interconnected network structure graphene as a conductive substrate, place it in a high-pressure reactor, and add 0.01mol / L KMnO to the high-pressure reactor 4 The solution is completely immersed...

Embodiment 2

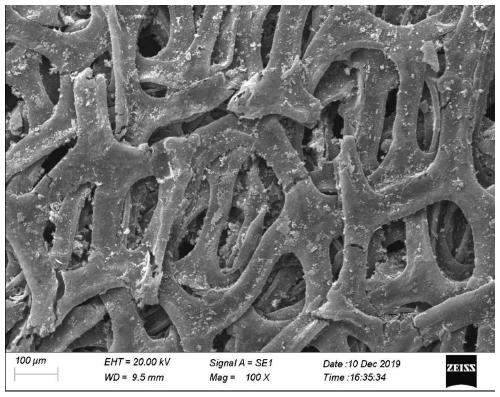

[0050] A preparation method of a nickel-based three-dimensional graphene / manganese dioxide composite material, comprising the steps of:

[0051] 1) Dissolve glucose in deionized water, prepare a glucose solution with a concentration of 1.2mol / L and place it in a quartz boat, use nickel foam as a substrate to immerse in the glucose solution, and transfer the entire quartz boat into a chemical vapor deposition furnace , in an argon atmosphere, chemical vapor deposition at 500°C for 0.5h, glucose carbonization in a high-temperature inert gas atmosphere, so that graphene carbon materials can be grown in situ on the nickel-based surface, that is, a nickel-based three-dimensional interconnected network structure is obtained Graphene;

[0052] 2) Use nickel-based three-dimensional interconnected network structure graphene as a conductive substrate and place it in a high-pressure reactor, and add 1mol / L KMnO to the high-pressure reactor 4 Solution until the conductive substrate is co...

Embodiment 3

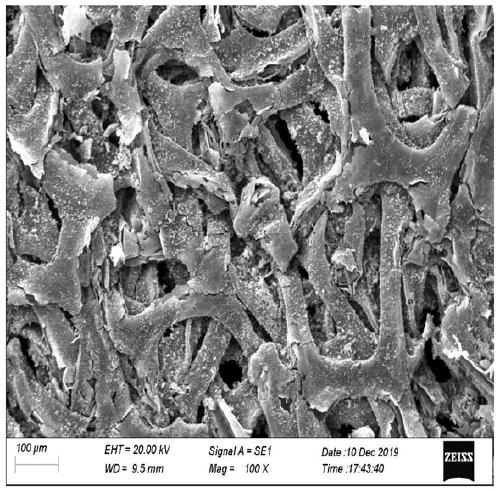

[0055] A preparation method of a nickel-based three-dimensional graphene / manganese dioxide composite material, comprising the steps of:

[0056]1) Dissolve polyvinyl alcohol in deionized water, prepare a polyvinyl alcohol solution with a concentration of 2mol / L and place it in a quartz boat, use foamed nickel as a base to immerse in the polyvinyl alcohol solution, and transfer the entire quartz boat into In a chemical vapor deposition furnace, in a nitrogen atmosphere, chemical vapor deposition is carried out at 800°C for 3 hours, and polyvinyl alcohol is carbonized in a high-temperature inert gas atmosphere, so that it grows graphene carbon material on the surface of the nickel base, that is, the nickel base Three-dimensional interconnected network structure graphene;

[0057] 2) The nickel-based three-dimensional interconnected network structure graphene is used as the conductive substrate and placed in a high-pressure reactor, and 3mol / L KMnO is added to the high-pressure r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com