A porous zirconium boride material, its preparation method and its application in the preparation of vinyl chloride by acetylene hydrochlorination

A technology of zirconium boride and boronizing agent, which is applied in the field of porous catalyst materials and can solve problems such as high price, poor mechanical strength of activated carbon, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides two methods for preparing porous zirconium boride materials described in the above schemes. The first method includes the following steps:

[0035] (1) After mixing the zirconium-containing precursor, boronating agent and solvent A, microwave digestion is carried out to obtain the mixed material;

[0036] (2) leave the mixed material to obtain a gel-like substance;

[0037] (3) drying the gel-like substance, and subjecting the dried material to boronation treatment under X-ray irradiation conditions to obtain a porous zirconium boride material.

[0038] In the invention, the zirconium-containing precursor, the boronating agent and the solvent A are mixed and then subjected to microwave digestion treatment to obtain the mixed material. In the present invention, the zirconium-containing precursor preferably includes zirconium oxide, zirconium chloride, zirconium nitrate, zirconium phosphate, zirconium sulfate, zirconium hydroxide, zirconiu...

Embodiment 1

[0058] (1) Weigh 12.32g of zirconia and 13.92g of boron oxide, add 15mL of ethanol, and use a microwave digestion apparatus to process at a frequency of 300GHz for 0.1h to obtain a mixed material;

[0059] (2) Put the above mixed material at 60°C for 1 hour to make it into a gel-like substance;

[0060] (3) drying the above-mentioned gelatinous substance at 110° C. and 10,000 Pa for 2 hours to obtain a dried material;

[0061] (4) The dry material is irradiated with X-rays under a nitrogen atmosphere, and the frequency of the radiation is 30EHz, so that the internal temperature of the dry material reaches 1100 ° C, and the boronization treatment is carried out for 3 hours;

[0062] (5) The material after the above-mentioned boride treatment is cooled to room temperature, and washed three times with deionized water;

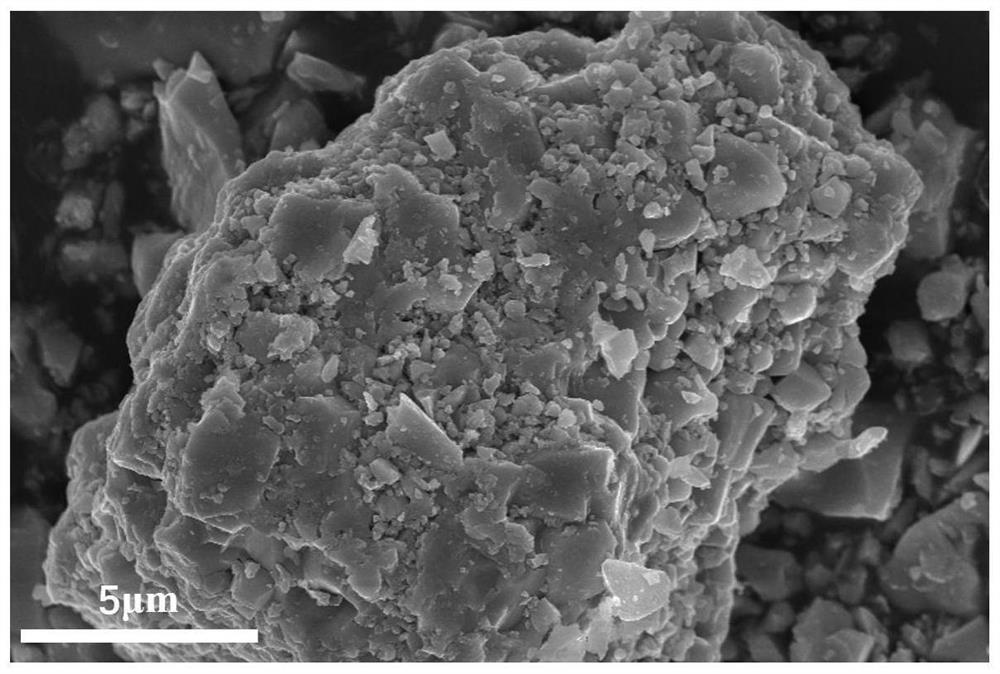

[0063] (6) Dry the zirconium boride material after the above-mentioned washing treatment for later use. The SEM image of the obtained zirconium boride material ...

Embodiment 2

[0067] (1) Weigh 23.3g of zirconium chloride and 8.3g of boron carbide, add 12mL of deionized water, and use a microwave digestion apparatus to process at a frequency of 300MHz for 1.5h to obtain a mixed material;

[0068] (2) Put the above mixed material at 90°C for 1.5h to make it into a gel-like substance;

[0069] (3) drying the above-mentioned gelatinous substance at 80° C. and 1000 Pa for 12 hours to obtain a dried material;

[0070] (4) The dry material is irradiated with X-rays under a nitrogen atmosphere, and the frequency of the radiation is 30PHz, so that the internal temperature of the dry material reaches 1300°C, and the boronization treatment is performed for 2.5 hours;

[0071] (5) The material after the boride treatment is cooled to room temperature, and washed three times with ethanol;

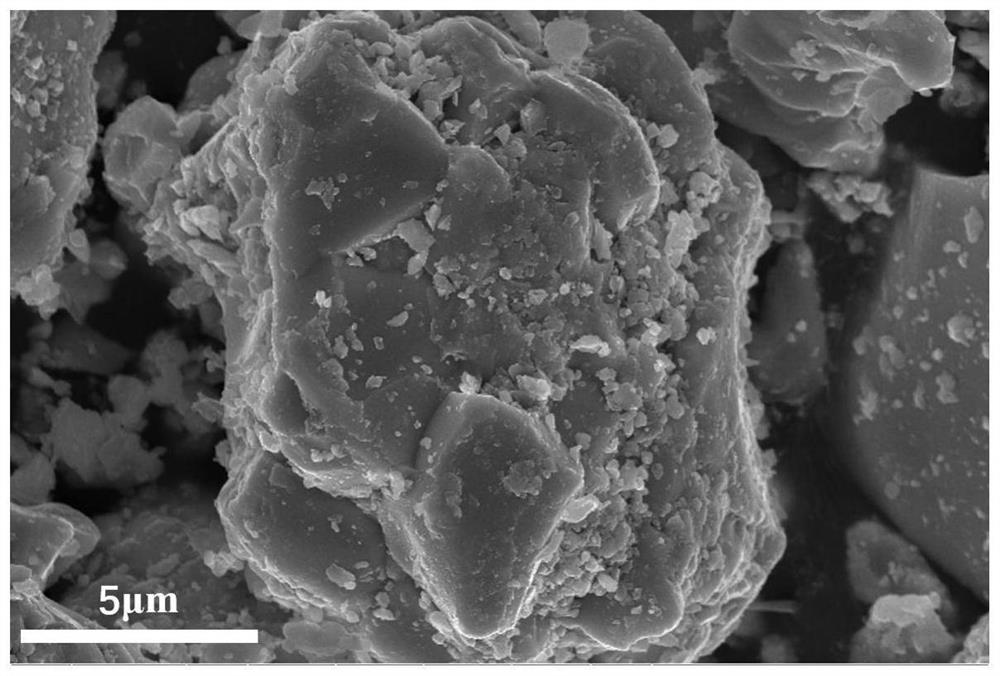

[0072] (6) The porous zirconium boride material after the above washing treatment is dried for subsequent use; the SEM image of the porous zirconium boride material obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com