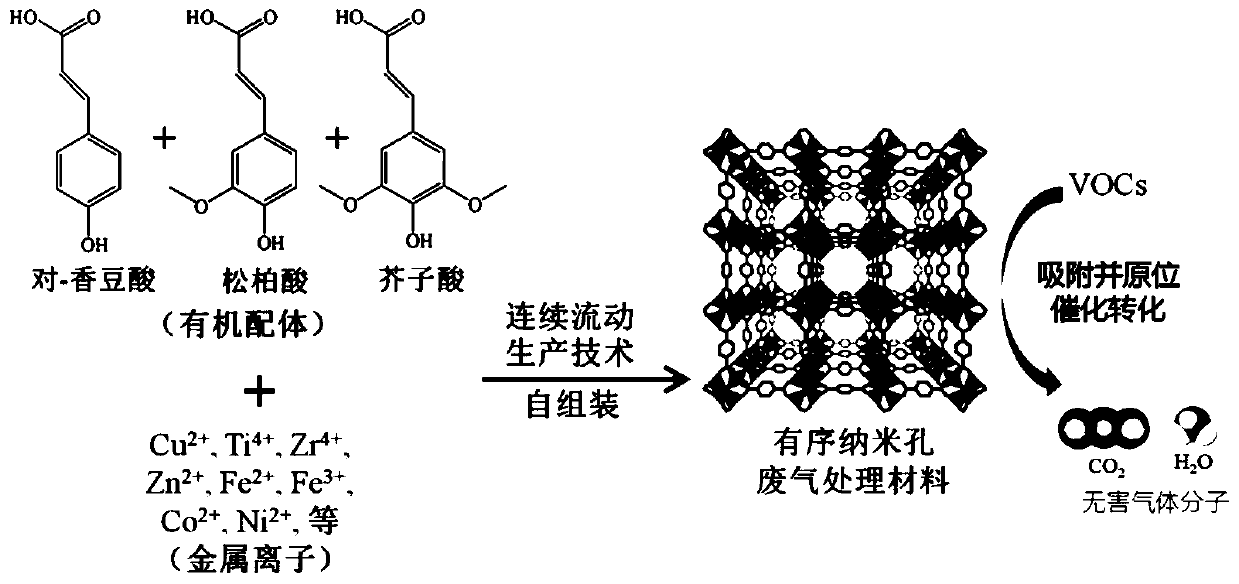

Method for synthesizing porous metal organic framework based on lignin degradation product

A porous metal and organic framework technology, applied in the field of metal organic framework, can solve the problems of low overall activity and limited high-quality field, and achieve the effect of simple process, mild experimental conditions and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 5 g of the lignin prepared in the above test example 1 was dispersed in 100 mL of water, and 0.5 g of solid base catalyst (aminopropyl functionalized mesoporous SBA-15 silica molecular sieve) was added to the lignin aqueous solution, mechanically Stir for 10 minutes to mix evenly. The speed of mechanical stirring is 800 rpm. Add 5 mL of commercially available hydrogen peroxide (30% by mass) to the mixed solution. At this time, the pH is 9.2. Under the microwave power of 200W, stir After 120 minutes, lignin was effectively converted into aromatic acid monomers, which were lignin degradation products and ligands for the subsequent preparation of porous metal organic frameworks.

[0079] Gel permeation chromatography was used to analyze the catalytic degradation products. The results showed that the molecular weight of lignin decreased significantly after the reaction, and the molecular weights of the degradation products were mainly distributed at 164, 194 and 224 Daltons,...

Embodiment 2~5

[0081] Using the same process as in Example 1, selecting different solid base catalyst quality, hydrogen peroxide volume, reaction pH, microwave power and reaction time, lignin degradation products with different effects can be obtained. The amounts of materials used and the reaction conditions are summarized in Table 1.

Embodiment 6

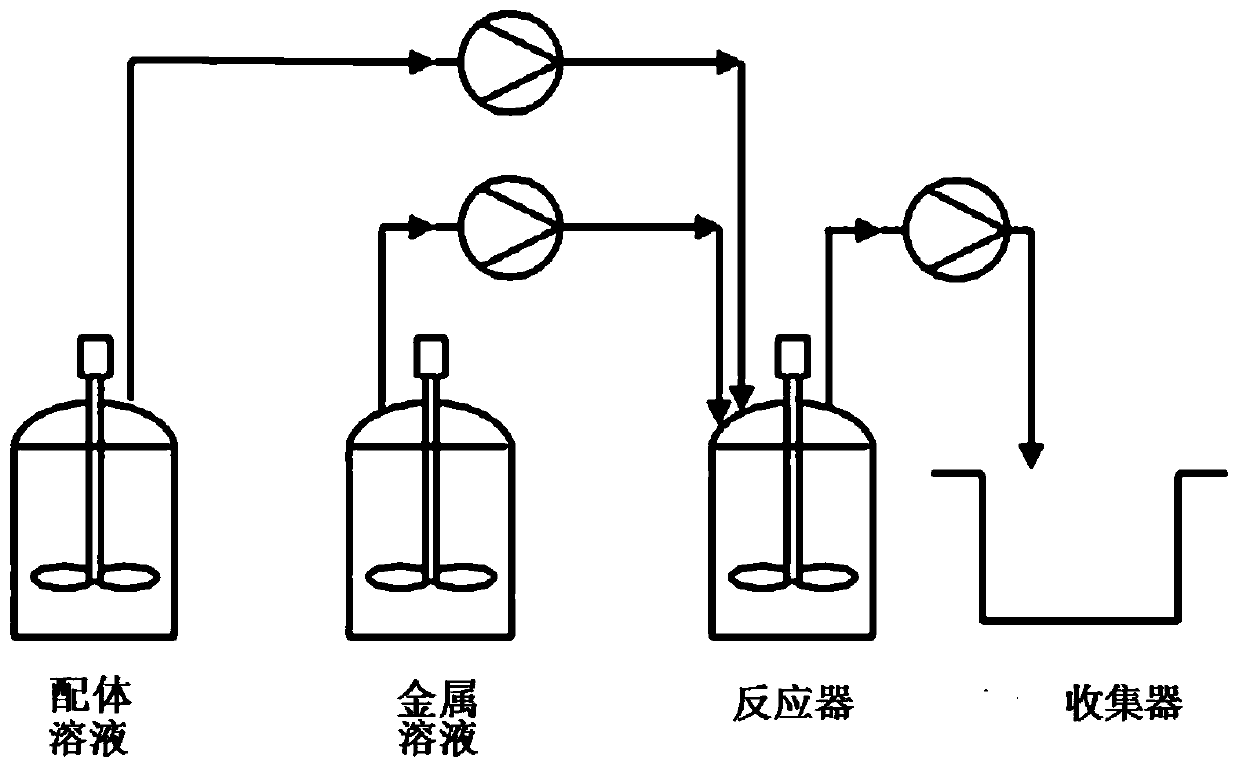

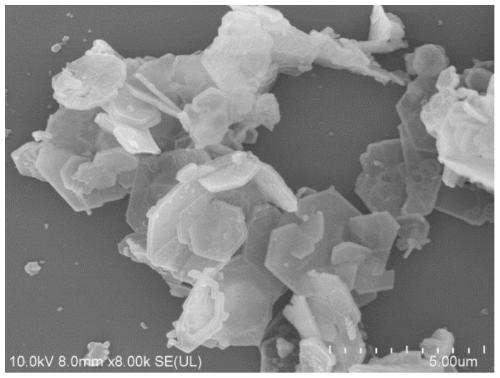

[0090] 2.5L of aromatic acid organic ligand solution (0.5mol L -1 , 1.26mol) and 210mL of ethanol were mixed uniformly to form a "ligand solution"; 2.5L of Cu(NO 3 ) 2 Aqueous solution (0.5mol·L -1 , 1.26mol), that is, "metal solution"; the "ligand solution" and "metal solution" reactants were continuously transferred to a 10L reactor equipped with a heating mantle at a feeding rate of 2mL / min, and the reaction The mixture was heated to 80°C and refluxed for 10 hours. After the reaction, it was transferred to a collector through an automatic control system, filtered and washed, and dried at 100°C for 12 hours to obtain a white powder, which was a porous metal organic framework.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com