A kind of equipment and process for producing biomass waste derived fuel

A biomass waste, derived fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of affecting production progress, occupying land, investment, labor and energy consumption, electrostatic repulsion, etc., to improve production and economy. Efficiency, saving drying equipment investment, saving time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

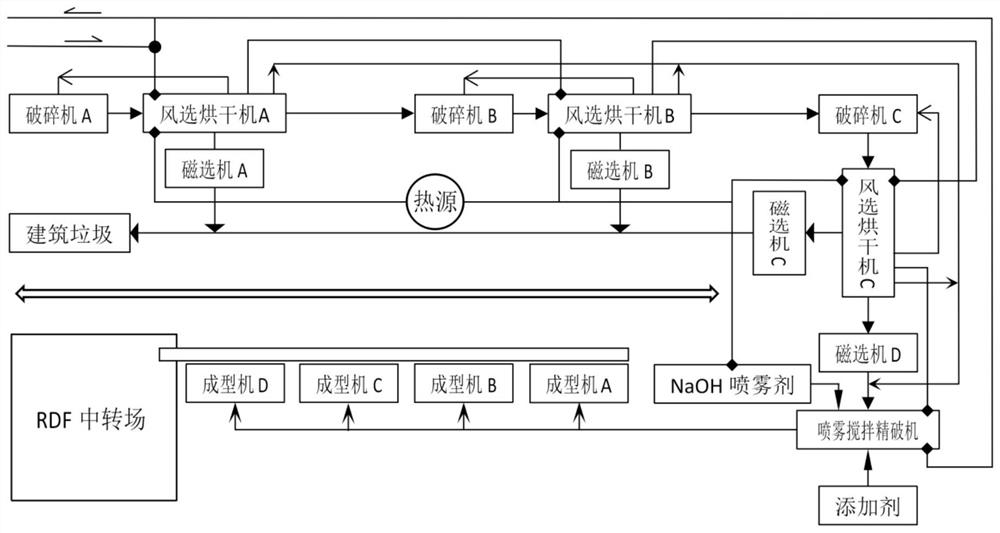

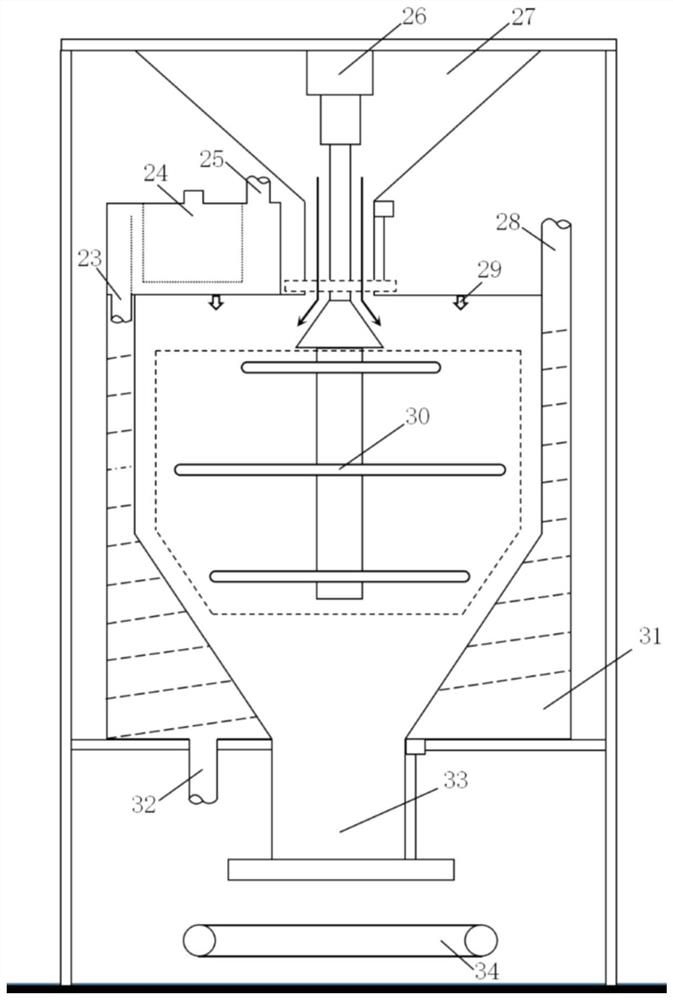

[0026] Such as Figure 1 to Figure 7 A device for producing fuel derived from biomass waste is shown, including crusher A, winnowing dryer A, bypass magnetic separator A, crusher B, winnowing dryer B, bypass magnetic separator B. Crusher C, wind separation dryer C, bypass magnetic separator C, main road magnetic separator D, spray stirring fine crushing and heating integrated machine, heat source, air duct, conveyor belt and forming machine;

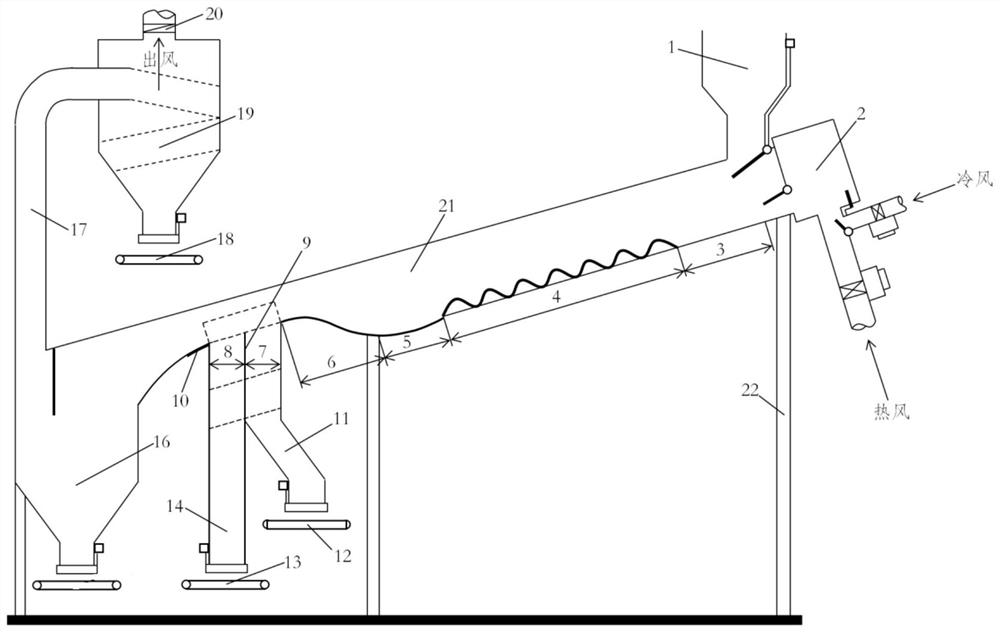

[0027] The winnowing dryer A, winnowing dryer B and winnowing dryer C have the same structure, and all include a length-adjustable base, a main controller and height-adjustable adjustable brackets connected to both sides of the upper end of the base 22. The winnowing dryer is a slanting type with one end high and the other end low, inclined downward along the direction of gravity and wind force, and the main controller controls the operation of the winnowing dryer; Equipped with feeding system, winnowing and drying system, hot air syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com