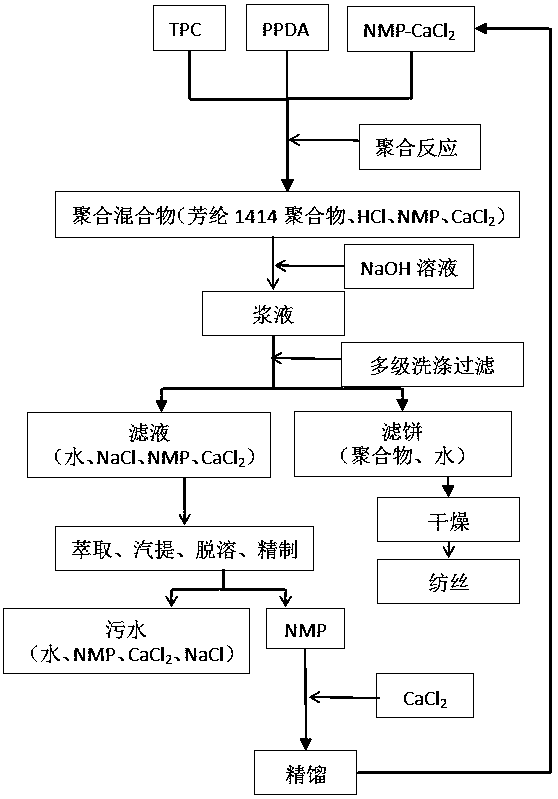

Polymerization solvent system recovery process in aramid fiber 1414 production

A solvent and aramid fiber technology, which is applied in the field of polymer production, can solve the problems of high residual calcium chloride, low yield and qualified rate, and inability to effectively control temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

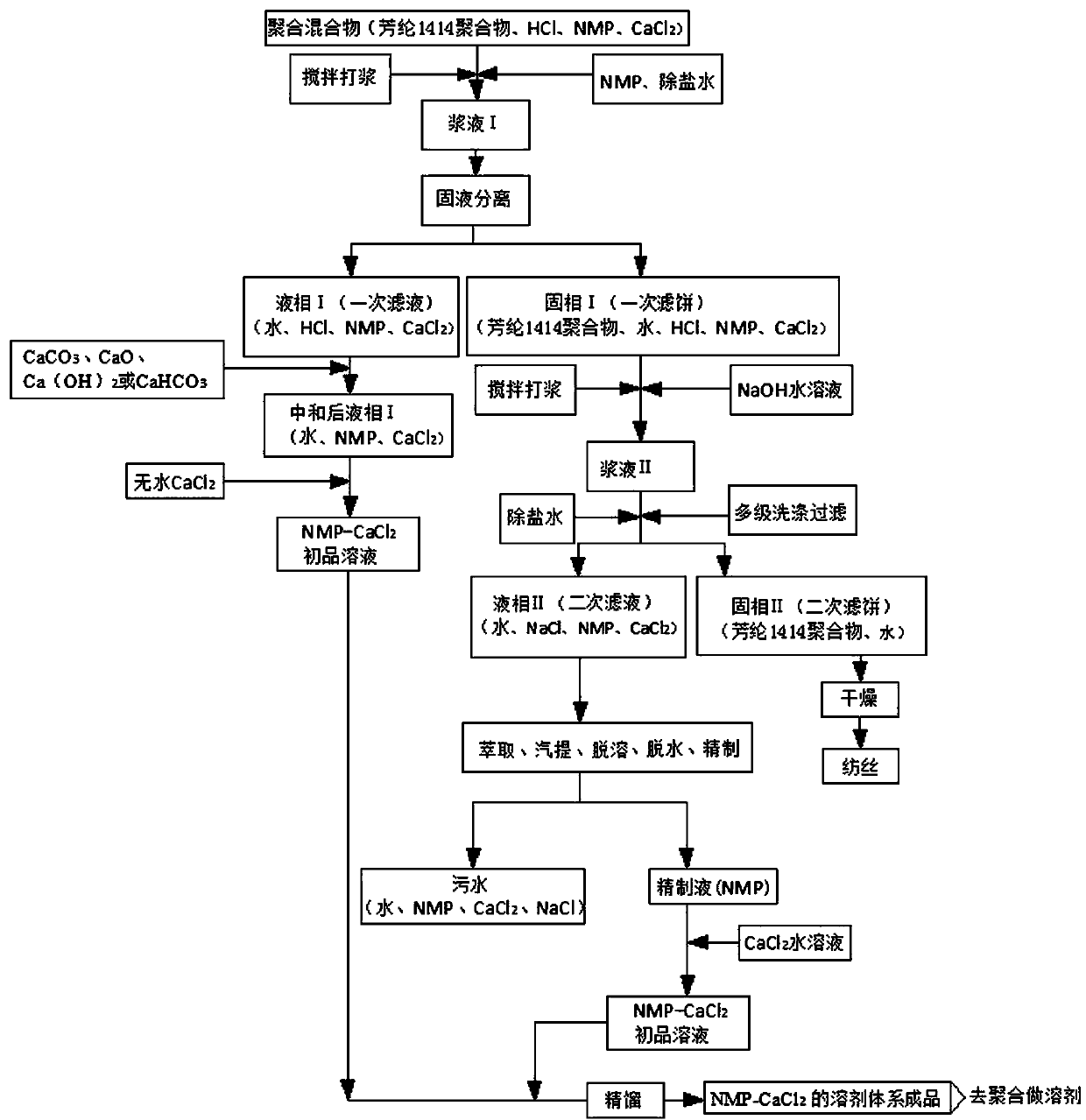

[0093] Such as image 3 Shown: a polymerization solvent system recovery process in the production of aramid fiber 1414, comprising the following steps:

[0094] 1) Add N-methylpyrrolidone and desalted water to the polymerization mixture, stir and beat to obtain slurry I;

[0095] 2) Separating the obtained slurry I from solid to liquid to obtain liquid phase I and solid phase I;

[0096] 3) Add aqueous sodium hydroxide solution to the obtained solid phase I, stir and beat until it becomes neutral or weakly acidic, and obtain slurry II;

[0097] Using desalinated water to carry out multi-stage washing and filtering of slurry II to obtain liquid phase II and solid phase II, and after drying solid phase II, aramid fiber 1414 polymer is obtained, which is ready for use;

[0098] Add extractant to extract liquid phase II to obtain raffinate and extract;

[0099] 4) After stripping the raffinate, it is directly discharged as sewage;

[0100] Desolventizing, dehydrating and refinin...

Embodiment 2

[0129] A polymerization solvent system recovery process in the production of aramid fiber 1414, comprising the steps of:

[0130] 1) Add N-methylpyrrolidone and desalted water to the polymerization mixture, stir and beat to obtain slurry I;

[0131] Wherein, the polymerization mixture refers to aramid fiber 1414 polymer with a content of 8-12%, N-methylpyrrolidone with a content of 78-88%, calcium chloride with a content of 4-11%, and a content of 2- 4% hydrogen chloride polymerization mixture;

[0132] Among them, in the total amount of N-methylpyrrolidone and desalted water added, the amount of N-methylpyrrolidone accounts for 40-90%, and the amount of desalinated water accounts for 10-60%;

[0133] 2) Separating the obtained slurry I from solid to liquid to obtain liquid phase I and solid phase I;

[0134] 3) Add aqueous sodium hydroxide solution to the obtained solid phase I to make the solution neutral or weakly acidic to obtain slurry II;

[0135] Using desalinated wa...

Embodiment 3

[0143] A polymerization solvent system recovery process in the production of aramid fiber 1414, comprising the steps of:

[0144] 1) Add N-methylpyrrolidone and desalted water to the polymerization mixture, stir and beat to obtain slurry I;

[0145] Wherein, in the polymerization mixture, including aramid fiber 1414 polymer with a content of 8%, N-methylpyrrolidone with a content of 85%, calcium chloride with a content of 4%, and hydrogen chloride with a content of 3%;

[0146] Wherein, in the total amount of N-methylpyrrolidone and desalted water added, the amount of N-methylpyrrolidone added accounts for 40%, and the amount of desalted water added accounts for 60%;

[0147] Wherein, the mass ratio between the polymerization mixture and the added N-methylpyrrolidone and desalted water is 1:1;

[0148] Among them, a stirring tank is used for stirring and beating, and the stirring and beating is set for 25 minutes, the motor frequency is 50HZ, and the slurry I is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com