Method for preparing hydrogen energy catalyst layered potassium titanate by utilizing screw extrusion

A catalyst layer and screw extrusion technology, applied in the field of photocatalysts, can solve the problems of complex semiconductor guest process, affecting large-scale stable preparation, and introducing instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

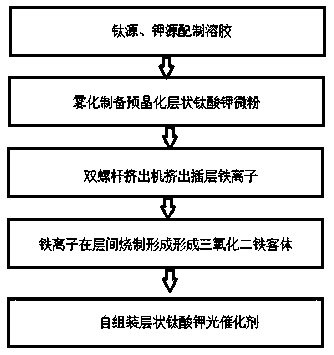

Image

Examples

Embodiment 1

[0028] A method for preparing hydrogen energy catalyst layered potassium titanate by screw extrusion, comprising the following steps:

[0029] (1) Butyl titanate, potassium citrate, ethanol, dilute nitric acid, and polyethylene glycol were formulated into a sol solution with a pH value of 2; the butyl titanate, potassium citrate, ethanol, dilute nitric acid, polyethylene glycol The mass ratio of diol is 60:40:40:60:13;

[0030] (2) Send the sol solution obtained in step (1) into the heat treatment chamber through high-pressure atomization, the pressure atomization pressure is 12Mp, the temperature of the heat treatment chamber is 850°C, and the heat treatment time is 40min to obtain precrystallized layered potassium titanate powder ;

[0031] (3) Disperse the pre-crystallized layered potassium titanate micropowder obtained in step (2) with ferric chloride hexahydrate, deionized water, n-butylamine aqueous solution, urea, and polyacrylamide to form a viscous substance, and dou...

Embodiment 2

[0034] A method for preparing hydrogen energy catalyst layered potassium titanate by screw extrusion, comprising the following steps:

[0035] (1) Butyl titanate, potassium citrate, ethanol, dilute nitric acid, and polyethylene glycol were formulated into a sol solution with a pH value of 3; the butyl titanate, potassium citrate, ethanol, dilute nitric acid, polyethylene glycol The mass ratio of diol is 80:60:30:40:10;

[0036] (2) The sol solution obtained in step (1) is sent to the heat treatment chamber through high-pressure atomization, the pressure atomization pressure is 12Mp, the temperature of the heat treatment chamber is 820°C, and the heat treatment time is 40min to obtain precrystallized layered potassium titanate powder ;

[0037](3) Disperse the pre-crystallized layered potassium titanate micropowder obtained in step (2) with ferric chloride hexahydrate, deionized water, n-butylamine aqueous solution, urea, and polyacrylamide to form a viscous substance, and dou...

Embodiment 3

[0040] A method for preparing hydrogen energy catalyst layered potassium titanate by screw extrusion, comprising the following steps:

[0041] (1) Butyl titanate, potassium citrate, ethanol, dilute nitric acid, and polyethylene glycol were formulated into a sol solution with a pH value of 3; the butyl titanate, potassium citrate, ethanol, dilute nitric acid, polyethylene glycol The mass ratio of diol is 70:30:40:60:14;

[0042] (2) The sol solution obtained in step (1) is sent to the heat treatment chamber through high-pressure atomization, the pressure atomization pressure is 10Mp, the temperature of the heat treatment chamber is 880°C, and the heat treatment time is 50min to obtain precrystallized layered potassium titanate powder ;

[0043] (3) Disperse the pre-crystallized layered potassium titanate micropowder obtained in step (2) with ferric chloride hexahydrate, deionized water, n-butylamine aqueous solution, urea, and polyacrylamide to form a viscous substance, and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com