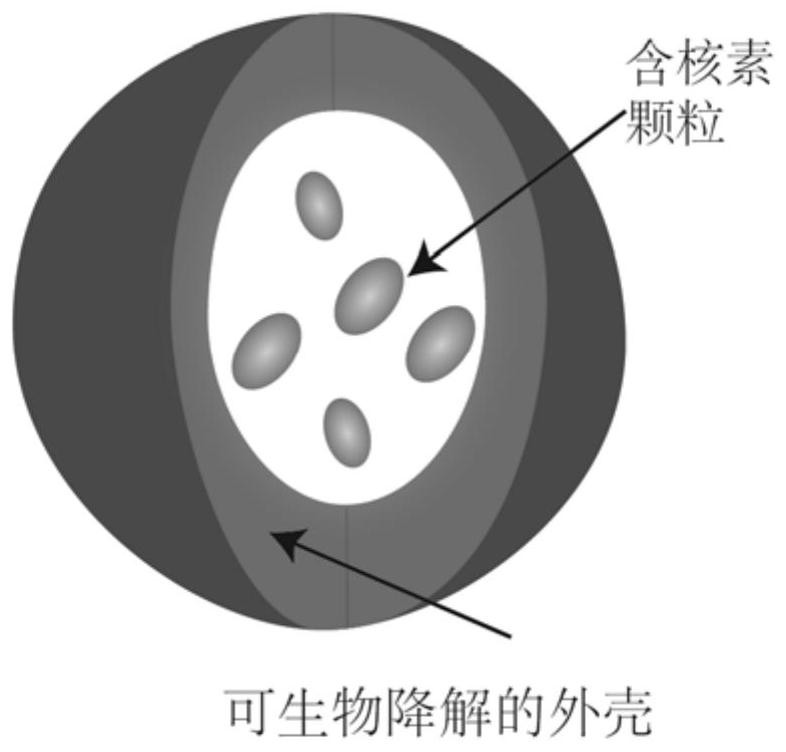

Radioactive embolization microsphere with core-shell structure and preparation method and application thereof

A core-shell structure, embolizing microsphere technology, applied in the field of medicine and medicine, can solve the problems of polymer chain breakage, leakage, radiation-sensitive normal organ damage, etc., and achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

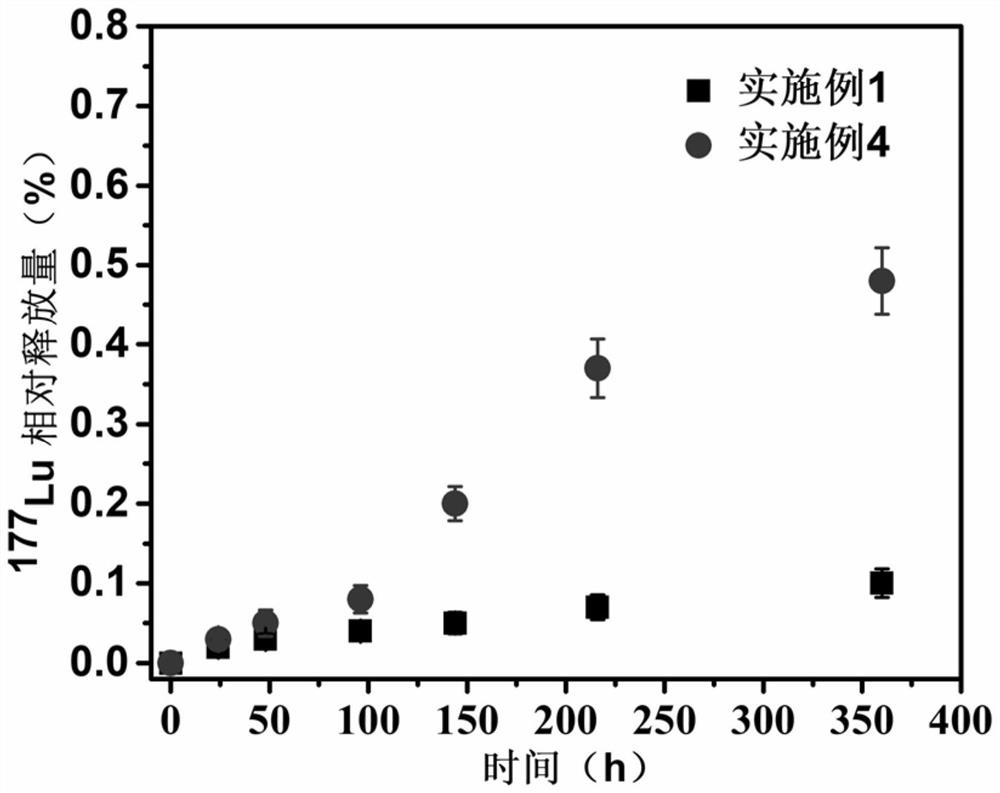

Embodiment 1

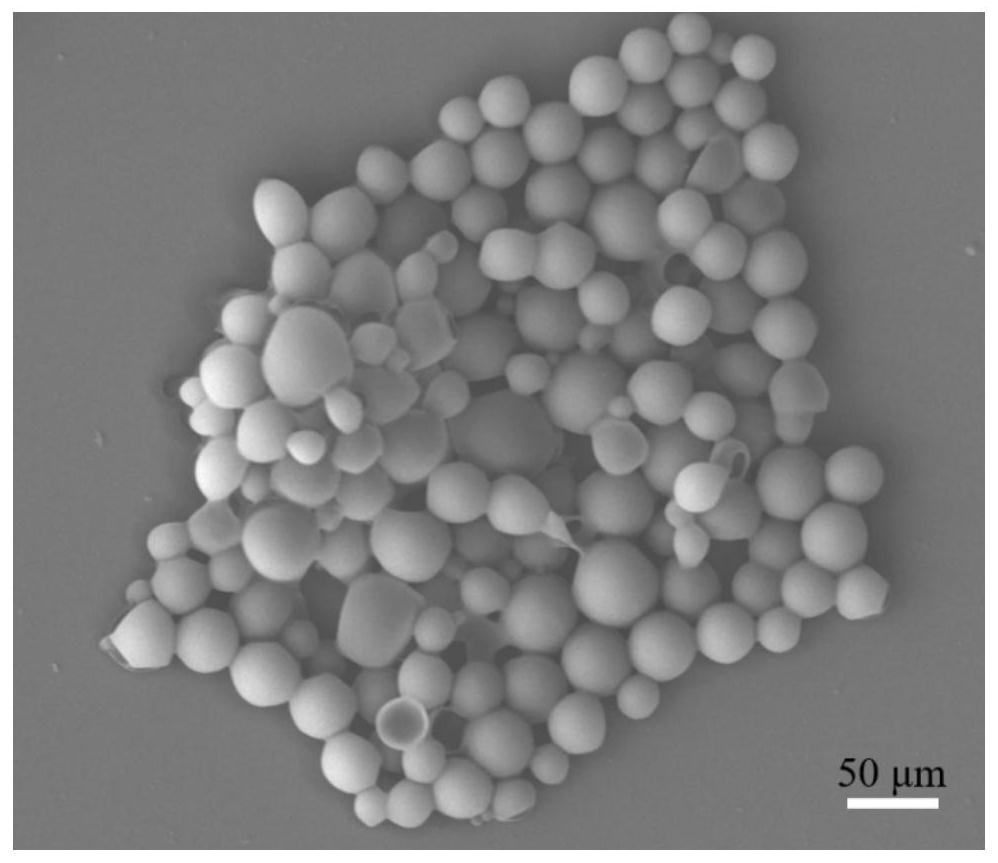

[0035] Embodiment 1 prepares embolization microspheres containing lutetium chloride

[0036] Weigh 2 g of lutetium chloride (LuCl 3 ) was dissolved in 1 ml of 0.5% w / v Pluronic F-68 in water. LuCl 3 The aqueous solution was added to 30ml of chloroform solution in which 2g of poly(lactide-glycolide) copolymer (PLGA) (molecular weight: ~20,000, Sigma, USA) was dissolved, placed on a magnetic stirrer and stirred at 2000rpm for 5min to obtain an emulsified liquid. Then, slowly add the above emulsion into 200ml of 2% (w / w) polyvinyl alcohol (PVA, molecular weight: 13,000-23,000, 87-89% hydrolyzed) aqueous solution and stir the above mixture at 1000rpm for 20h to obtain micro ball. Microspheres were collected by centrifugation and washed three times with double distilled water to remove excess PVA. Disperse the washed microspheres into 50 ml of cryoprotectant solution (25 mM glycerol, 0.5% w / v Pluronic F-127, 0.1% w / v sucrose, 3% w / v mannitol and 5% w / v polyethylene glycol 400...

Embodiment 2

[0039] Example 2 Preparation of Embolization Microspheres Containing Yttrium Phosphate Nanoparticles

[0040] 8.4mmol of yttrium chloride (YCl 3 , Sigma-Aldrich, USA) and phosphoric acid (H 3 PO 4 , Sigma-Aldrich, USA) was dissolved in 300 mL of double distilled water. With constant stirring, 150ml of 56mM NaOH solution was slowly added to the above-mentioned yttrium nitrate-phosphoric acid solution, and the stirring was continued for 20min to obtain an opaque suspension. The suspension was centrifuged at 4000 rpm for 5 min to collect the white precipitate. The precipitate was washed three times with double distilled water. In a vacuum environment, dry the above-mentioned yttrium phosphate nanoparticles. Weigh 2.0 g of yttrium phosphate nanoparticles into 10 ml of 0.2% w / v In the F-68 (ThermoFisher, USA) aqueous solution, the yttrium phosphate nanoparticles were uniformly dispersed in the aqueous solution by ultrasonication for more than 30 minutes, and then the larger ...

Embodiment 3

[0043] Example 3 Preparation of phospholipid-coated holmium acetylacetonate embolization microspheres

[0044] Measure 200 mg of dipalmitoylphosphatidylcholine (DPPC, Avanti, USA), 150 mg of dipalmitoylphosphatidylglycerol (DPPG, Avanti, USA) and 150 mg of distearoylphosphatidylethanolamine-polyethylene glycol with an analytical balance. Diol (DSPE-mPEG2000, Avanti, USA) was placed in a flask, 25ml of propylene glycol (Sigma-Aldrich, USA) and 25ml of glycerin (Sigma-Aldrich, USA) were added, and heated in a water bath at 65°C for 20min until the phospholipids were dissolved , then add 150ml of distilled water (65°C) and continue heating in a water bath at 65°C for 20min to obtain a homogeneous phospholipid solution, then cool to room temperature to obtain a phospholipid solution (2.5mg / ml).

[0045] Weigh 2 g of holmium acetylacetonate (HoAcAc, Sigma-Aldrich, USA) and add 3 ml of chloroform to dissolve. Add the chloroform solution to 15ml of the phospholipid solution (2.5mg / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com