Controllably degradable high-strength magnesium-based composite scaffold coating and preparation method thereof

A technology for composite stents and magnesium alloy stents, which is applied in the field of controllable degradation of high-strength magnesium-based composite stent coatings and its preparation, and can solve problems such as inability to provide stable support, decreased structural and performance stability, and failure of implanted stents , to achieve the effect of good cytocompatibility and blood compatibility, good hydrophilicity and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention provides a method for preparing a controllable degradation high-strength magnesium-based composite stent coating, which comprises the following steps:

[0034] (1) Prefabrication of degradable magnesium alloy stent matrix: the magnesium alloy microtubes were laser cut into vascular stents, and the vascular stents were electrochemically polished in a perchloric acid alcohol solution with a concentration of 4.25% by mass; after polishing, they were treated with NaOH, Na 2 CO 3 、C 12 H 25 SO 4 Sonochemical degreasing was carried out in Na and OP-10 strong alkaline mixed solution for 3min at 60°C; in 85% H 3 PO4 and NH 3 Remove the surface oxide layer in the mixed solution of HF to obtain a passivated surface with stable potential;

[0035] (2) Treatment of the degradable magnesium alloy stent matrix: the degradable magnesium alloy stent matrix treated in step (1) was placed in Na 4 P 2O 7 10H 2 O, ZnSO4 7H 2 O solution system, then add the corrosio...

Embodiment 2

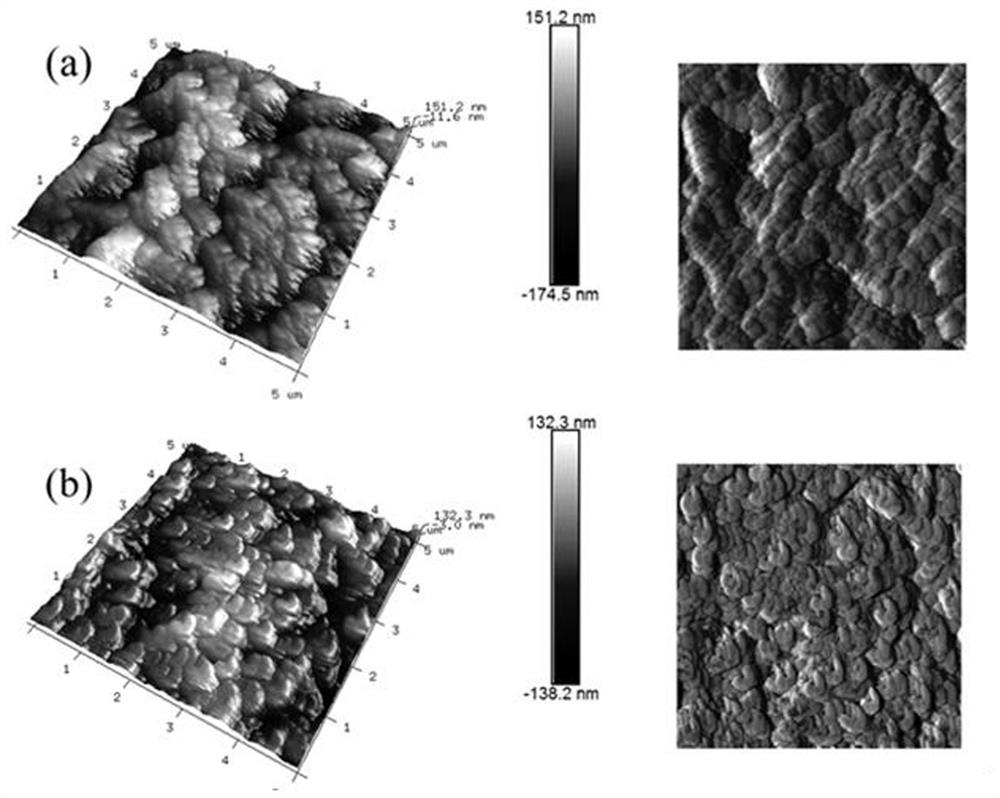

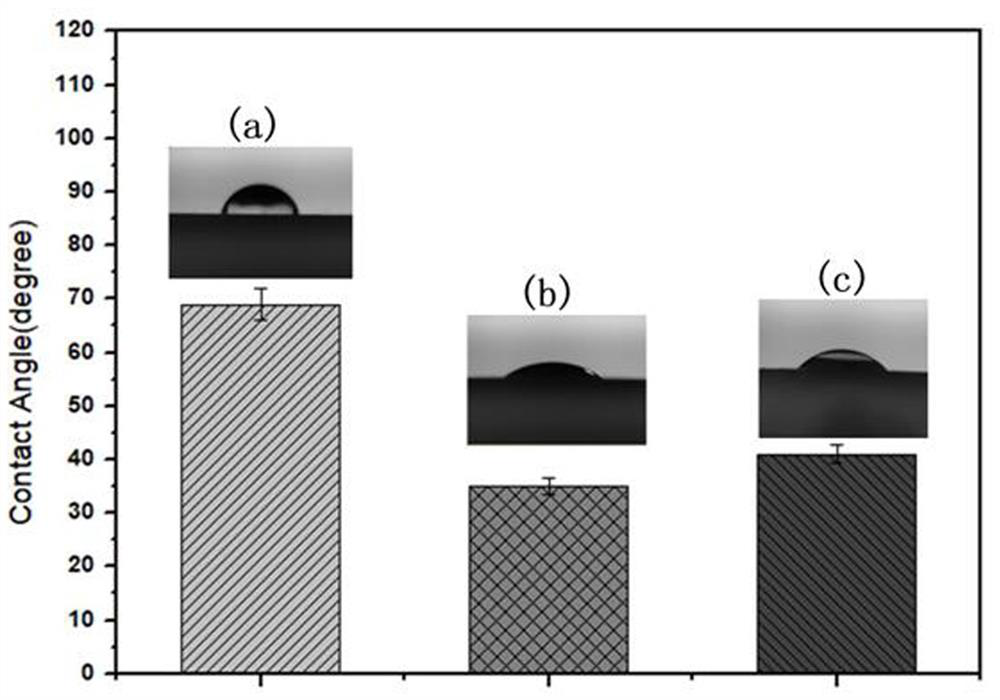

[0041] The experimental conditions and operation process of steps (1) and (2) in this example are the same as those in Example 1, and the current density of single-pulse electrodeposition in step (3) is changed to 7A / dm 2 , the specific implementation steps are in the NaOH, ZnO solution system, adding KNaC 4 H 4 O 6 ·4H 2 O was used as impurity remover, pure zinc plate was used as anode, magnesium alloy substrate was used as cathode, 260-type platinum electrode was used as auxiliary electrode, and protective zinc layer was prepared in single pulse mode, pulse frequency was 1000HZ, duty ratio was 10%, deposition temperature The temperature was 55°C, and the deposition time was 20 min. After the preparation was completed, it was rinsed with deionized water for 1 min, and dried with cold air at 25°C. Its AFM test such as figure 1 As shown in (a), the coating grains are fine and the roughness value Ra is 38.5nm; figure 2 As shown in (b), the wetting angle of the water contac...

Embodiment 3

[0043] The experimental conditions and operation process of steps (1) and (2) in this example are the same as those in Example 1, and the single-pulse electrodeposition in step (3) is changed to DC electrodeposition mode. The specific implementation steps are in the NaOH and ZnO solution system, Add KNaC 4 H 4 O 6 ·4H 2 O is used as impurity remover, pure zinc plate is used as anode, magnesium alloy substrate is used as cathode, 260-type platinum electrode is used as auxiliary electrode, and the protective zinc layer is prepared in DC mode. The deposition temperature is 55℃ and the current density is 3A / dm 2 , the deposition time is 20min, after the preparation is completed, rinse with deionized water for 1min to remove the residual solution on the surface, and dry it with cold air at 25°C.

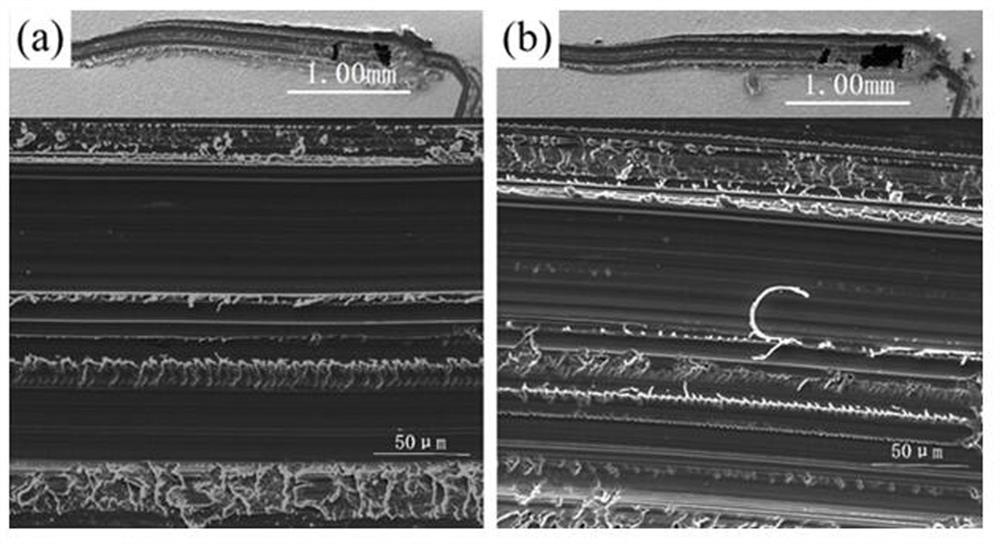

[0044] After the preparation is completed according to the described steps, it can be observed by scanning electron microscope, such as Image 6 As shown in (a), the zinc layer on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com