Method for separating carnosine and histidine

A separation method and technology for histidine, applied in the field of separation of carnosine and histidine, can solve the problems of low yield, low purity of carnosine, difficult separation, etc., and achieve reduced production cost and energy consumption, high selective separation capability , the effect of simplifying the separation step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

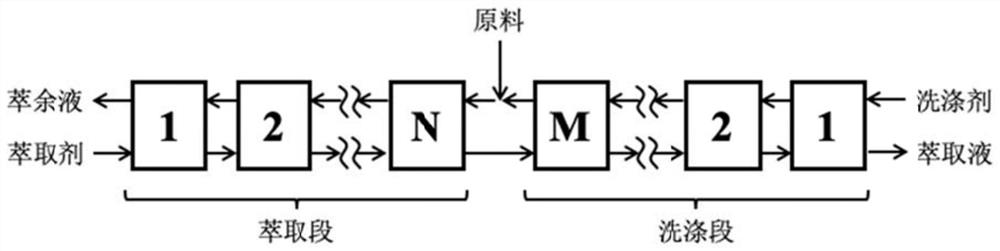

Method used

Image

Examples

Embodiment 1

[0049] Prepare a two-phase aqueous system consisting of polyethylene glycol 400, ammonium sulfate, and water, wherein the volume ratio of polyethylene glycol 400 to water is 3:10, and the mass ratio of ammonium sulfate to water is 1:2. After equilibrium, the light phase is polyethylene glycol + water phase, and the heavy phase is ammonium sulfate + water phase, and the light and heavy phases are taken out for later use. A mixture of raw materials carnosine and histidine (carnosine / histidine=18.77%, mass ratio) was dissolved in the light phase to prepare a raw material solution. The heavy phase is used as the extractant, the light phase is used as the detergent, and the flow ratio of the extractant, raw material liquid, and detergent is 2:0.6:7. Fractional extraction is carried out at 25°C. There are 20 stages in the extraction section, and the washing section A total of 20 stages, collecting the extract and raffinate. The purity of carnosine in the extract was 98.37%, and the...

Embodiment 2

[0051] According to the mass ratio of polyethylene glycol 2000: ammonium sulfate: water = 22.54:50:100, the two-phase aqueous system was prepared and pre-balanced. The light phase was polyethylene glycol + water phase, and the heavy phase was ammonium sulfate + water phase. Light and heavy two-phase standby. A mixture of raw materials carnosine and histidine (carnosine / histidine=18.77%, mass ratio) was dissolved in the light phase to prepare a raw material solution. The heavy phase is used as the extractant, the light phase is used as the detergent, and the flow ratio of the extractant, raw material liquid, and detergent is 1:1:9. Fractional extraction is carried out at 25°C. There are 7 stages in the extraction section, and the washing section There are 16 stages in total, and the extract and raffinate are collected. The purity of carnosine in the extract was 99.11%, and the yield was 91.69%; the purity of histidine in the raffinate was 98.46%, and the yield was 99.85%.

Embodiment 3

[0053] Prepare a two-phase aqueous system composed of polyethylene glycol 400, dipotassium hydrogen phosphate, water, wherein the volume ratio of polyethylene glycol 400 and water is 3:10, and the mass ratio of dipotassium hydrogen phosphate and water is 3: 10. After pre-equilibration, the light phase is polyethylene glycol + water phase, and the heavy phase is dipotassium hydrogen phosphate + water phase. Take out the light and heavy phases for later use. A mixture of raw materials carnosine and histidine (carnosine / histidine=18.77%, mass ratio) was dissolved in the light phase to prepare a raw material solution. The heavy phase is used as the extractant, the light phase is used as the detergent, and the flow ratio of the extractant, raw material liquid, and detergent is 1:0.01:0.98. Fractional extraction is carried out at 25°C. There are 30 stages in the extraction section, and the washing section There are 30 stages in total, and the extract and raffinate are collected. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com