Antibiotic mushroom dreg microbial fertilizer and preparation method thereof

A technology of antibiotic bacteria residue and microbial fertilizer, which is applied in the direction of fertilizer made from biological waste, microbial treatment, organic fertilizer, etc., can solve the problems of large amount of pollutants, high operating cost, waste of resources, etc., and achieve renewable utilization , protect the ecological environment, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

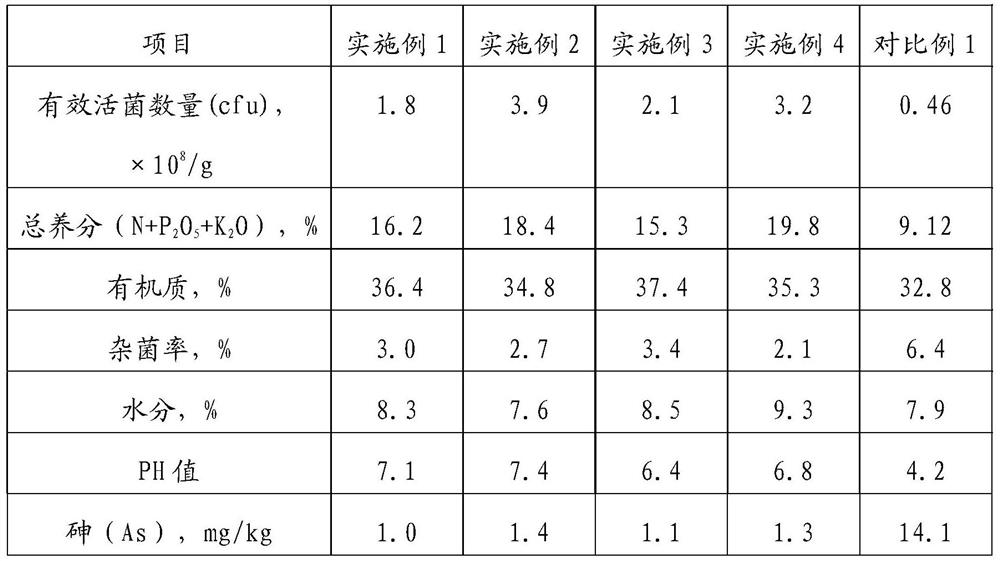

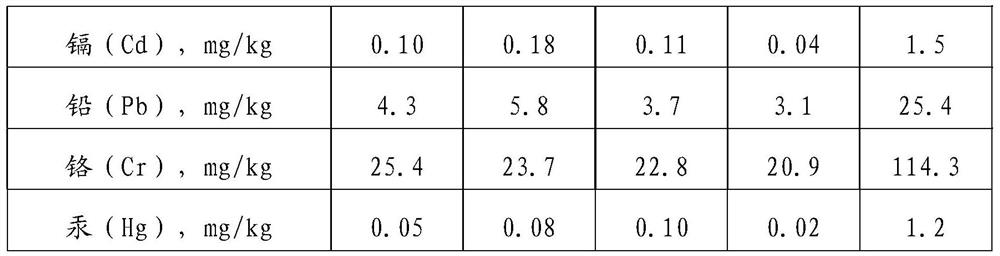

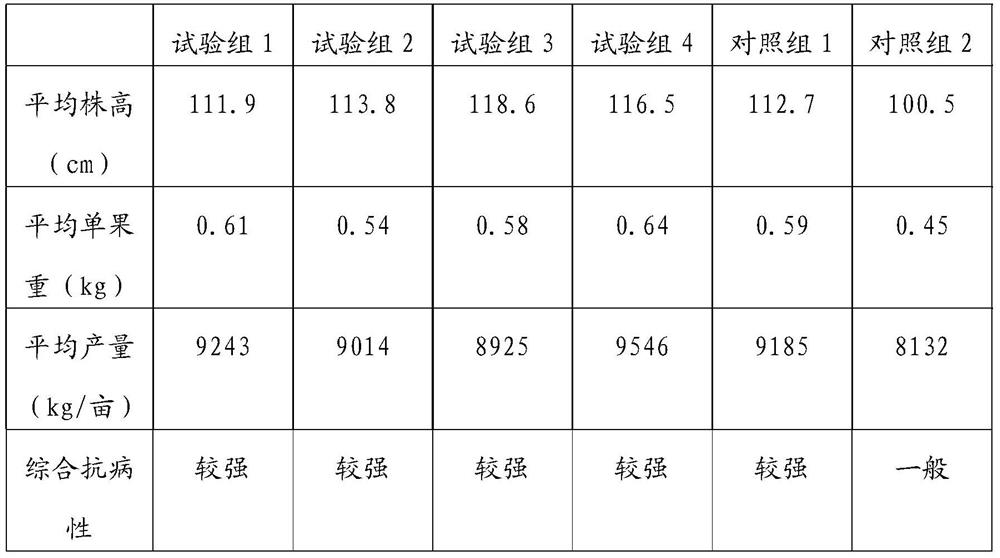

Examples

Embodiment 1

[0032] The preparation method of the antibiotic slag microbial fertilizer of the present embodiment comprises the following steps:

[0033] (1) Preparation of organic fertilizer: Mix 0.2kg of poultry manure, 0.1kg of vermicompost and 0.7kg of sludge evenly, adjust the moisture content of the mixture to 55-60%, and put it into the tank for stacking, and the height of the pile is set to 1.5 m, when the temperature of the pile rises above 55°C, turn the pile once every 6 hours to ensure that the temperature of the pile remains below 55°C, and the fermentation time of tank composting is 10-15 days. Among them, poultry manure is 100g of chicken manure and 100g of pig manure.

[0034] (2) Preparation of inorganic fertilizer: 300g of calcium carbide slag is placed in water and mixed, stirred evenly, then add 100g of potassium phosphate, after stirring for 2h, filter to obtain potassium salt solution and residue, then slowly add hydrochloric acid solution in the residue until No gas ...

Embodiment 2

[0044] The preparation method of the antibiotic slag microbial fertilizer of the present embodiment comprises the following steps:

[0045] (1) Preparation of organic fertilizer: Mix 0.4kg of poultry manure, 0.1kg of vermicompost and 0.5kg of sludge evenly, adjust the moisture content of the mixture to 55-60%, and put it into the tank for stacking, and the height of the pile is set to 1.5 m, when the temperature of the pile rises above 55°C, turn the pile once every 6 hours to ensure that the temperature of the pile remains below 55°C, and the fermentation time of tank composting is 10-15 days. Among them, poultry manure is 100g of chicken manure, 200g of pig manure and 100g of sheep manure.

[0046] (2) Preparation of inorganic fertilizer: method is the same as Example 1, and concrete steps are with reference to Example 1, but the calcium carbide slag that adds wherein is 300g, and potassium phosphate is 200g.

[0047] (3) Pretreatment of antibiotic residues: place polypepti...

Embodiment 3

[0055] The preparation method of the antibiotic slag microbial fertilizer of the present embodiment comprises the following steps:

[0056] (1) Preparation of organic fertilizer: Mix 0.3kg of poultry manure, 0.2kg of vermicompost and 0.5kg of sludge evenly, adjust the moisture content of the mixture to 55-60%, and put it into the tank for stacking, and the height of the pile is set to 1.5 m, when the temperature of the pile rises above 55°C, turn the pile once every 6 hours to ensure that the temperature of the pile remains below 55°C, and the fermentation time of tank composting is 10-15 days. Among them, poultry manure is 100g of chicken manure, 100g of pig manure and 100g of cow manure.

[0057] (2) Preparation of inorganic fertilizer: method is the same as Example 1, and concrete steps are with reference to Example 1, but the calcium carbide slag that adds wherein is 500g, and potassium phosphate is 200g.

[0058] (3) Pretreatment of antibiotic residues: place aminoglycos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com