Polydopamine modified nanofiber coating-based nanofiltration membrane and preparation method thereof

A nanofiber and polydopamine technology, which is applied in the field of membrane separation, can solve the problems of high requirements in the preparation process of graphene oxide quantum dots, insignificant improvement of pure water flux, complicated preparation process of composite nanofiltration membrane, etc. High fiber surface roughness, synergistic improvement of water flux and retention rate, and the effect of improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

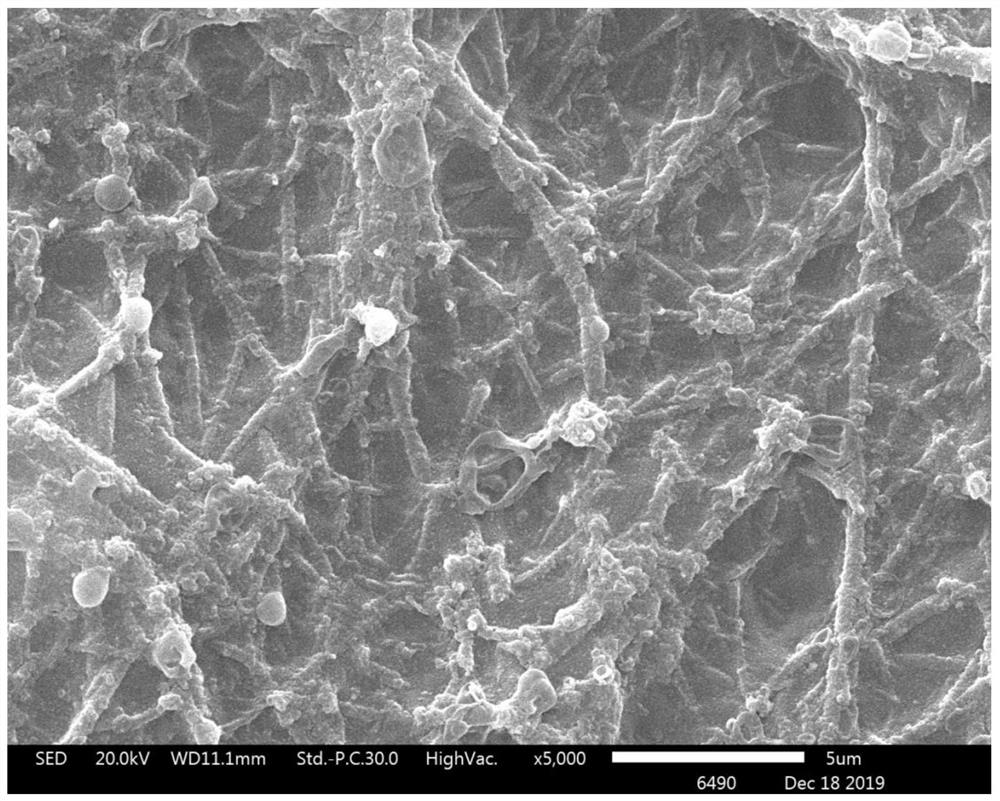

[0039] The present invention also provides a method for preparing the above-mentioned polydopamine-modified nanofiber coating-based nanofiltration membrane, comprising the steps of:

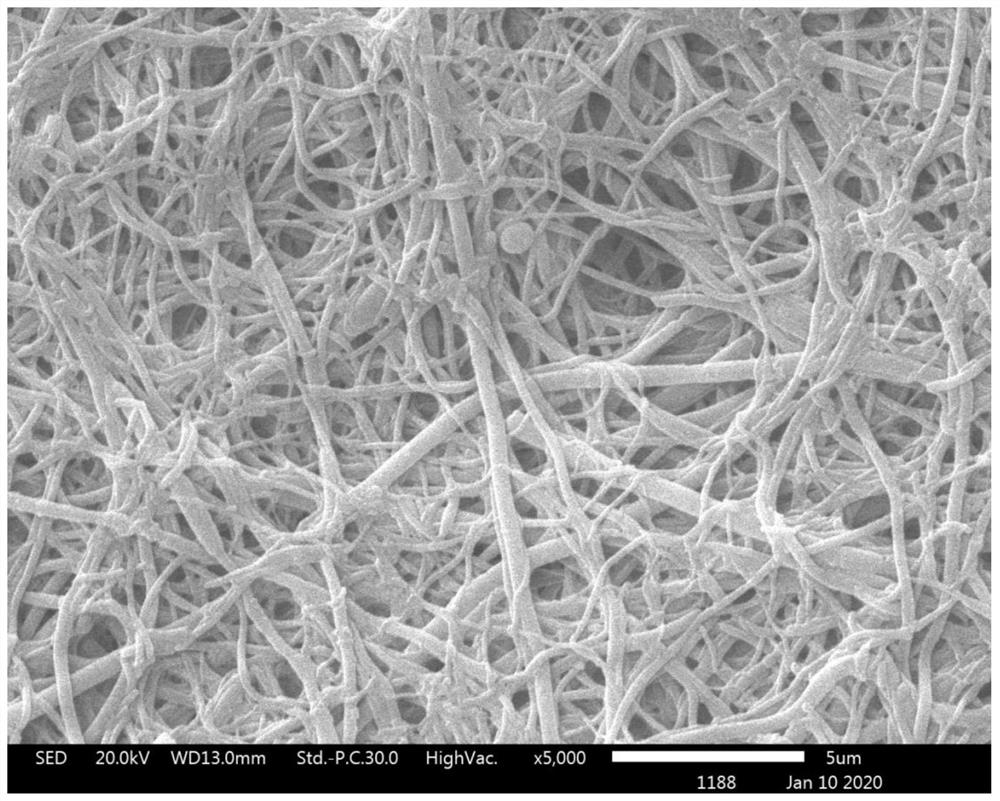

[0040] S1. Uniformly dispersing ethylene vinyl alcohol copolymer nanofibers with a diameter of 50-500 nm in a solvent to obtain a nanofiber dispersion with a solid content of nanofibers of 0.2-6 wt %;

[0041] S2. Apply the nanofiber dispersion obtained in step S1 on the surface of the nonwoven substrate by using wet nonwoven technology, and control the coating thickness to 2-10 μm, and the coating density to be 5-10 g / m 2 ; After the coating is completed, it is often dried in vacuum at high temperature to obtain a nanofiber coating film;

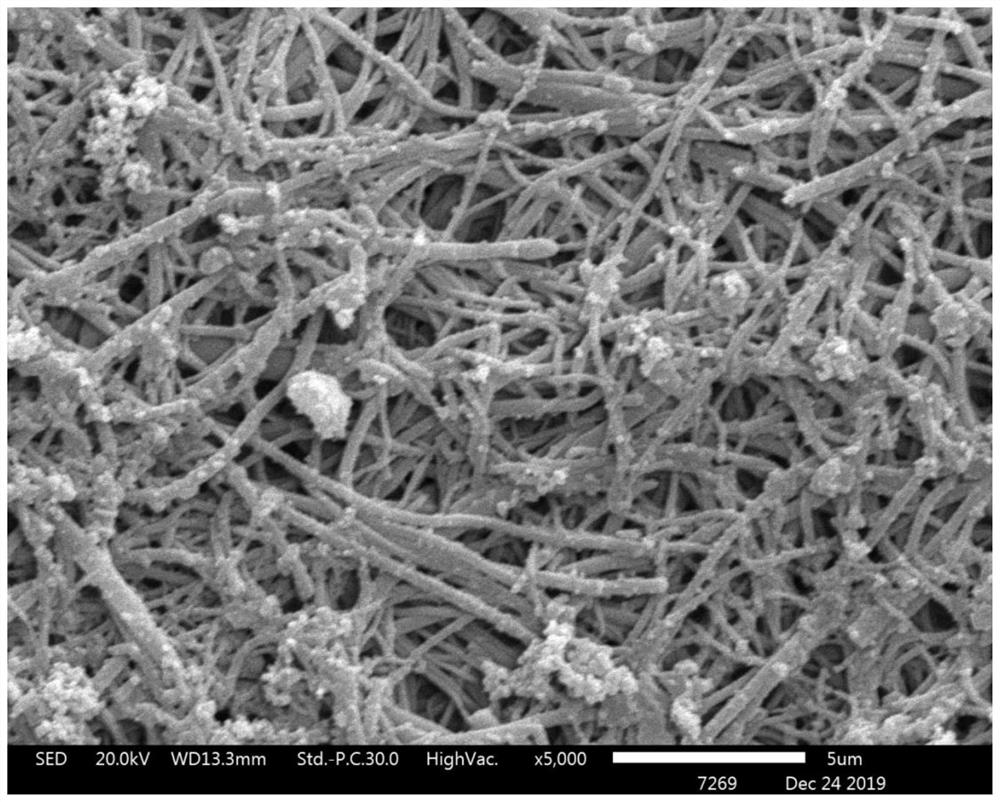

[0042] S3. Prepare a Tris buffer solution, and add lye to adjust the pH of the buffer solution to 8-9 to obtain a weakly alkaline buffer solution; dissolve a predetermined amount of dopamine hydrochloride in the weakly alkaline buffer solution In, obtain th...

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of polydopamine modified nanofiber coating-based nanofiltration membrane, comprising the following steps:

[0051] S1. Disperse ethylene vinyl alcohol copolymer nanofibers with a diameter ranging from 50 to 500 nm in a mixed solvent with a mass ratio of ethanol and deionized water of 1:1, and stir thoroughly to obtain nanofibers with a solid content of 0.5 wt%. Nanofiber dispersion liquid, sealed for future use.

[0052] S2. Apply the nanofiber dispersion obtained in step S1 on one surface of the polypropylene spunbonded nonwoven fabric substrate by spraying, the coating thickness is 5 μm, and the coating density is 5 g / m 2 ; After the coating is completed, vacuum drying is carried out at room temperature to obtain a nanofiber coating film.

[0053] S3, preparation concentration is the Tris-HCl (Tris-HCl) buffer solution of 0.1mol / L, and adopts sodium hydroxide to adjust the pH of buffer solution to 8.5, obta...

Embodiment 2~13

[0060] Embodiment 2~13 provides a kind of preparation method of polydopamine modified nanofiber coating base nanofiltration membrane, compared with embodiment 1, the difference is that some parameter values of the preparation process are adjusted, and the remaining steps are all the same as the implementation Example 1 is the same and will not be repeated here. The specific parameter values corresponding to each embodiment are shown in Table 1.

[0061] The relevant preparation parameter of table 1 embodiment 2~13

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com