Oil-resistant low-smoke halogen-free flame-retardant flexible polyurethane cable material and preparation method thereof

A cable material, polyurethane prepolymer technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of mechanical properties that cannot meet the index requirements, high hardness, and insufficient insulation properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

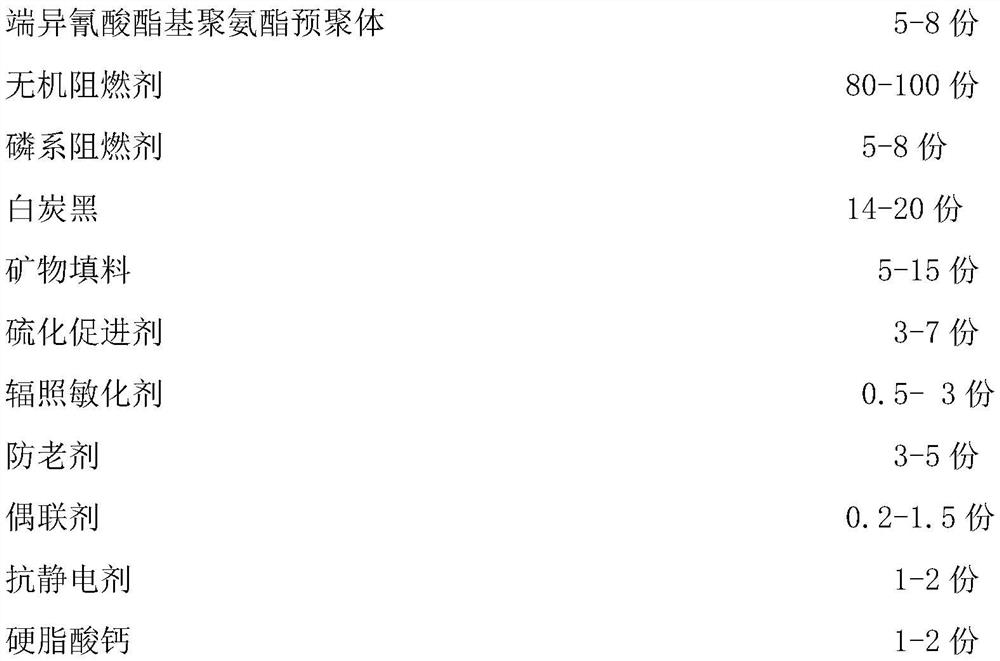

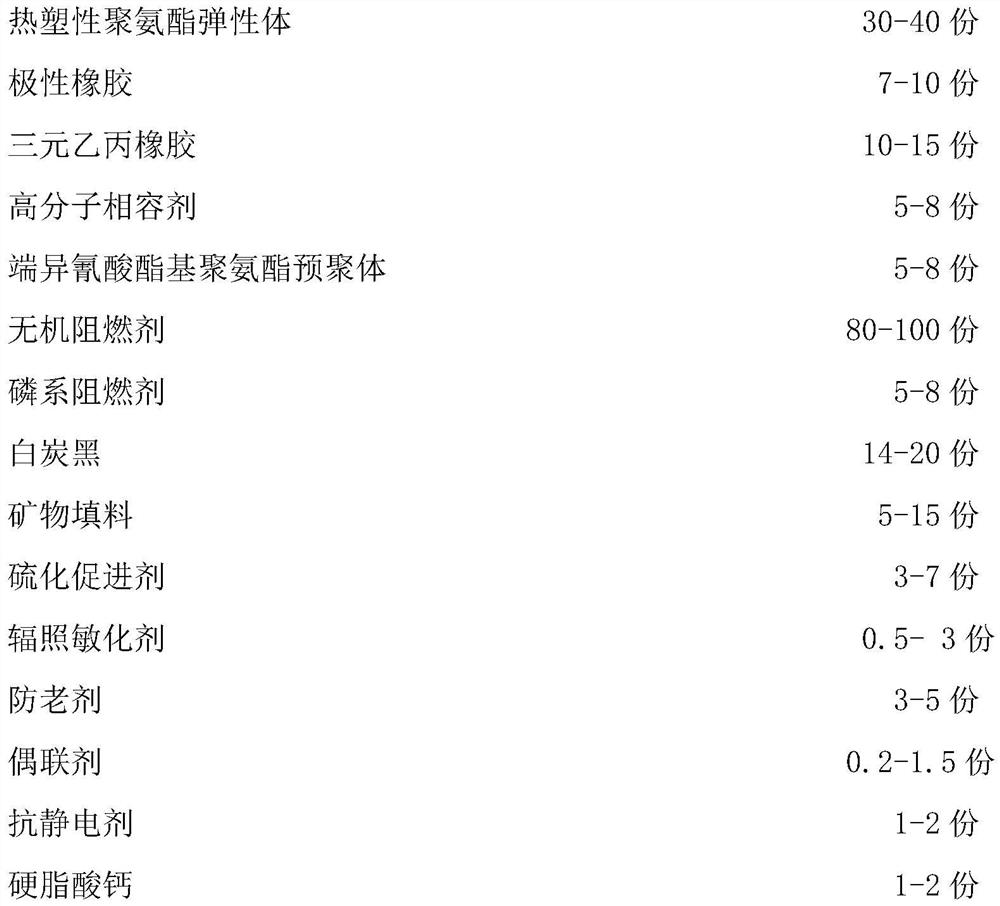

[0070] The preparation method of the above-mentioned oil-resistant, low-smoke, halogen-free and flame-retardant flexible polyurethane cable material comprises the following steps:

[0071] (1) First weigh thermoplastic polyurethane elastomer, ethylene-vinyl acetate rubber, EPDM rubber, ethylene-methyl acrylate-glycidyl methacrylate terpolymer, polyether-type terminal isocyanate group according to the formula ratio Polyurethane prepolymer, magnesium hydroxide, aluminum hydroxide, zinc borate, pentaerythritol phosphate, silica, mineral filler, N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxy Phenyl)propionyl)hexanediamine, 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl), Cytec V703, γ-aminopropyl triethyl Oxysilane, trihydroxyethylmethyl quaternary ammonium methosulfate, calcium stearate, the weighed white carbon black, inorganic flame retardant and mineral filler are premixed to obtain the primary mixed filler, and the prepared The isocyanate-terminated polyurethane prepolymer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com