Method for transforming lignin into phenolic acid by using lentinus edodes fermentation culture

A technology for fermentation and cultivation of lignin, which is applied in the field of using mushroom fermentation and cultivation to convert lignin into phenolic acid, can solve the problems of polluting the environment, easily generating a large amount of waste liquid, waste residue and waste gas, and achieves small pollution opportunities, high output, low cost cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of improved potato dextrose broth medium:

[0033] Take 200g of potatoes, 20g of glucose, 0.5-2g of lignin, 20g of hemicellulose, and deionized water;

[0034] Cut the potatoes into small pieces, put them in deionized water, boil for a certain period of time (such as 20-30min), filter with multi-layer gauze, take the filtrate, add water to make it 1000ml, add glucose, lignin, and hemicellulose to dissolve completely, Adjust the pH to 6.0, and after aliquoting, sterilize under high pressure steam at 126° C. and 0.15 MPa for 30 minutes to obtain the modified potato dextrose broth medium.

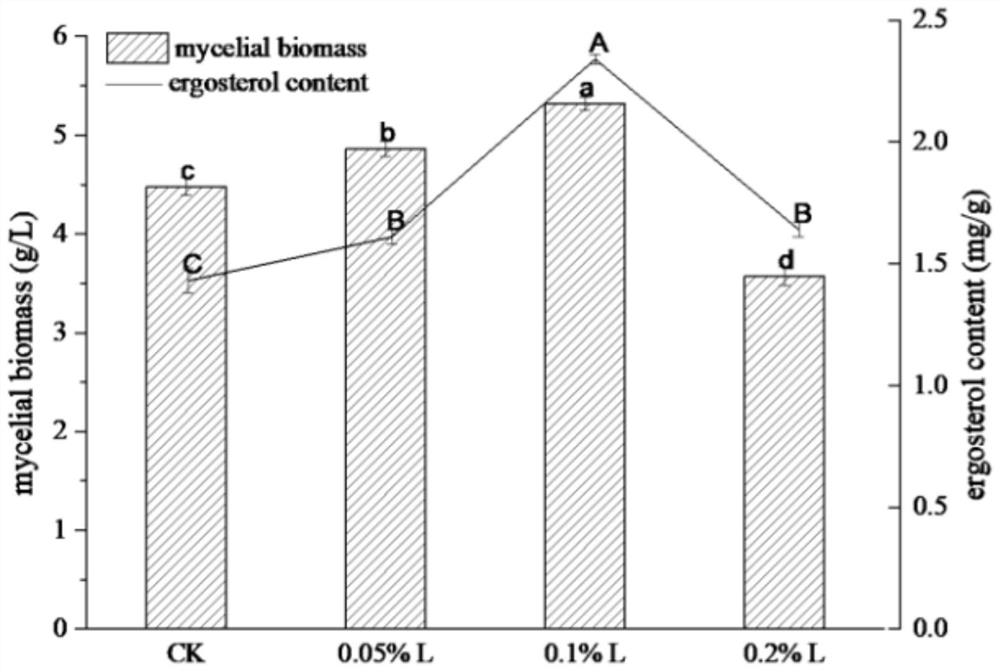

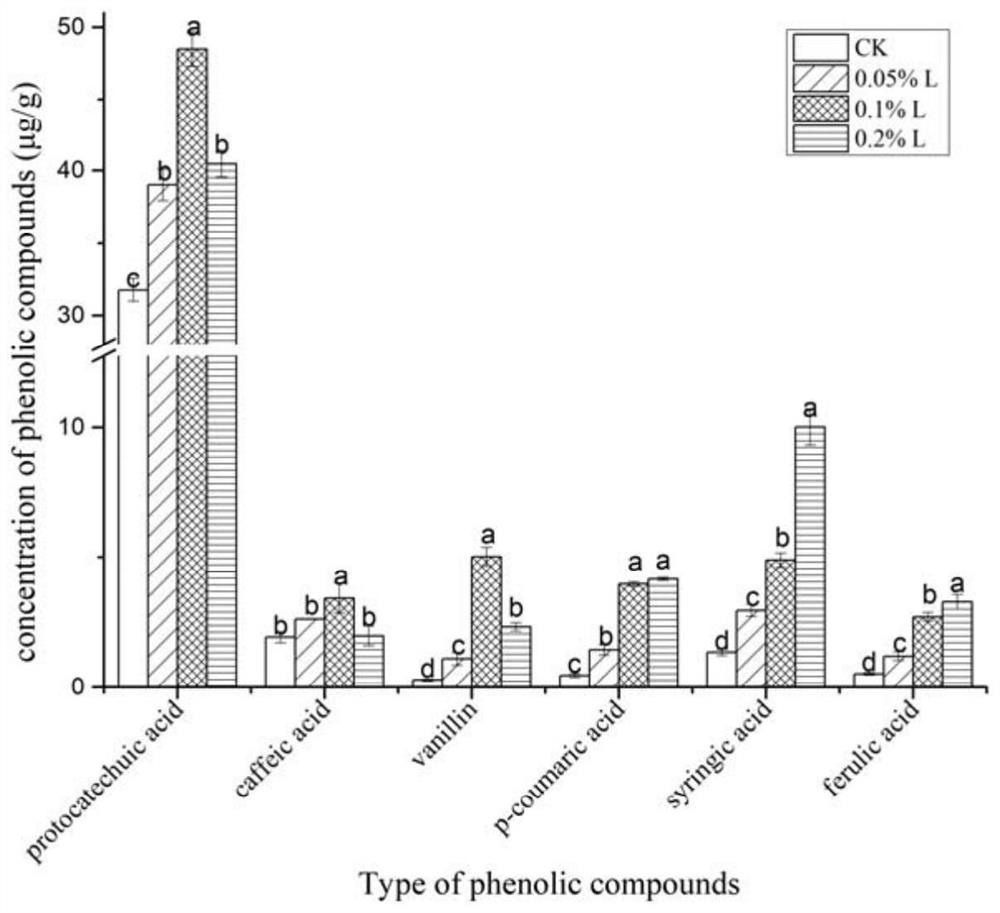

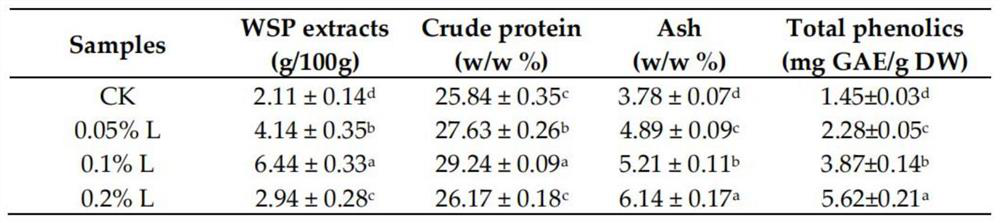

[0035] Lentinus edodes mycelium fermentation and cultivation method: inoculate the lentinus edodes mycelium under sterile conditions, shake the flask for 10 days in a constant temperature shaking incubator at 28° C. and 160 rpm, and collect the lentinus edodes mycelium by centrifugation.

[0036] The collected mushroom mycelium is freeze-dried and then the phenol...

Embodiment 1

[0038] A method utilizing shiitake mushrooms to ferment and transform lignin into phenolic acids, the method comprising:

[0039] a) using improved potato dextrose broth medium, inoculating shiitake mushroom mycelia under aseptic conditions, and culturing in a shaking flask at 28° C. and 160 rpm in a constant temperature shaking incubator for 10 days;

[0040] Wherein, the concentration of lignin in the improved potato dextrose broth medium is 0.05% g / mL, and the concentration of hemicellulose is 2% g / mL;

[0041] b) collecting the mycelia and freeze-drying, and calculating the mycelium biomass;

[0042] Mycelium biomass was measured as follows: y=m 1 / v 1 , where y is mycelium biomass (g / L), m 1 is the dry weight of mycelium (g), v 1 is the volume of medium (L);

[0043]c) Dissolve the freeze-dried mycelia powder in acetonitrile and hydrochloric acid solution, ultrasonically extract for 30 minutes, bathe in 30°C water for 2 hours, and spin dry; redissolve in methanol to ...

Embodiment 2

[0046] This example provides a method for transforming lignin into phenolic acids by fermenting and cultivating shiitake mushrooms, which is basically the same as Example 1, except that in step a), the concentration of lignin in the improved potato dextrose broth medium 0.1% g / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com