Metal-fluorine doped carbon composite material as well as preparation method and application thereof in electrocatalytic nitrogen fixation

A technology of carbon composite materials and composite materials, which is applied in the fields of electrochemistry, catalysis and material synthesis, can solve the problems of low activity and selectivity of nitrogen reduction electrocatalysts, improve reaction activity and selectivity, reduce costs, and have high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

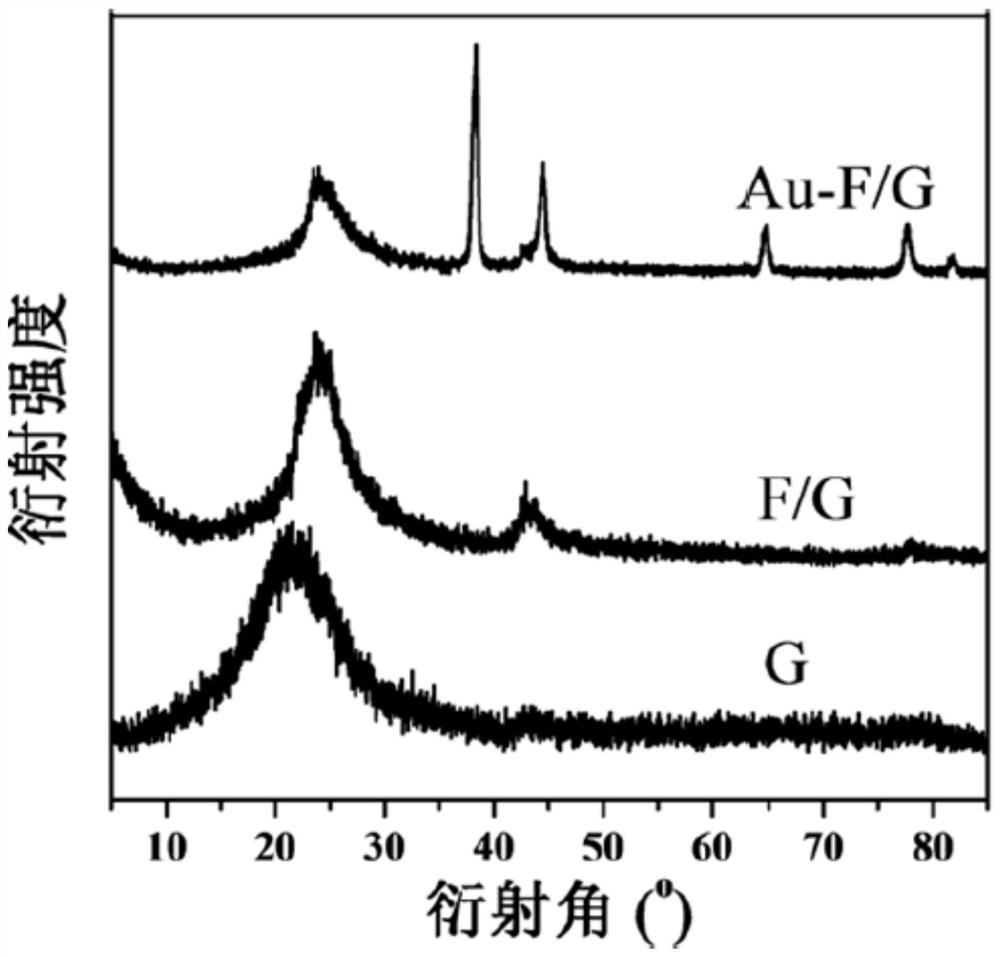

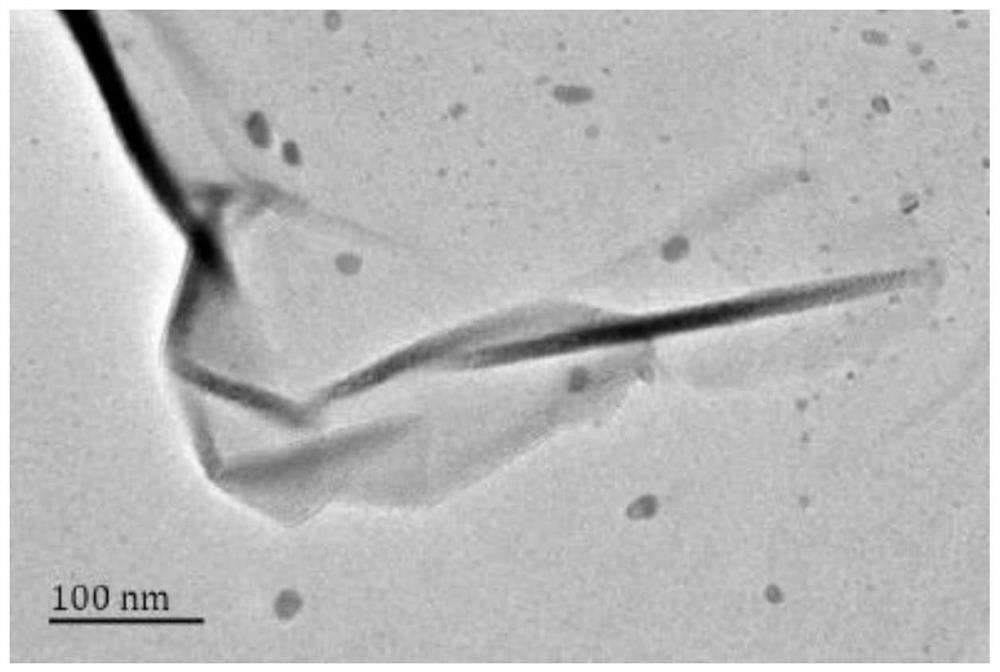

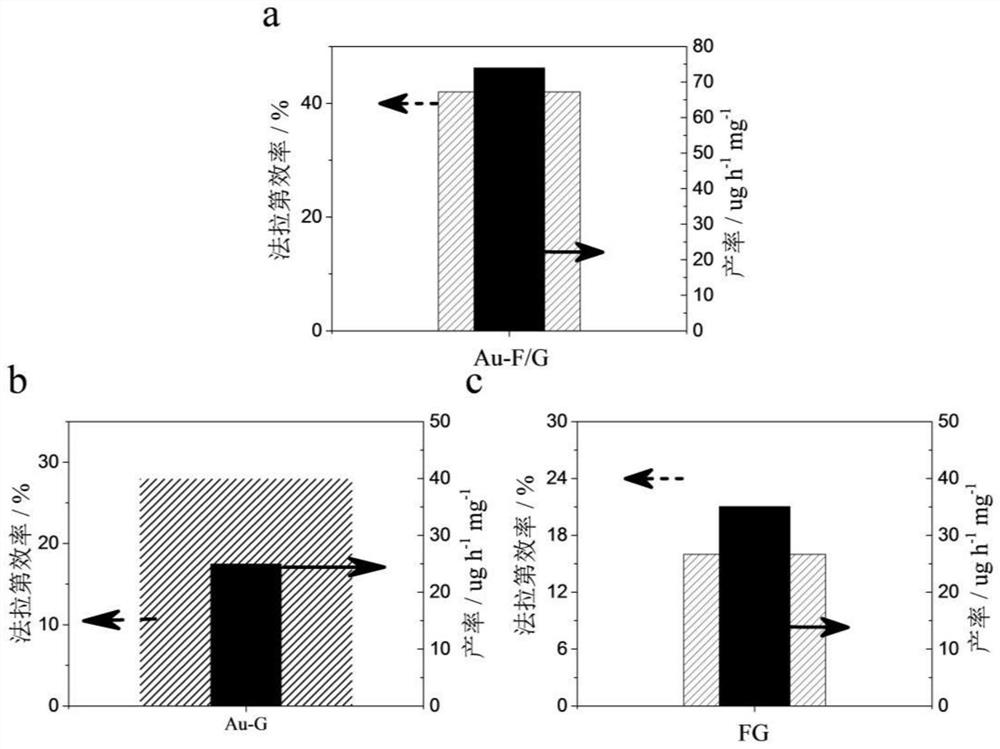

[0058] Embodiment 1 uses graphite oxide and chloroauric acid as raw materials to prepare Au-F / G composite material

[0059] (1) Preparation of graphene oxide: graphene oxide was prepared by the improved hummer method, and the process was as follows: 1.5 g of phosphorus flake graphite was mixed with 35 ml of concentrated sulfuric acid and 0.75 g of sodium nitrate, and stirred for 16 hours. Then add 4.5g of potassium permanganate at 0°C and stir for 2h. The system was warmed up to room temperature, continued to stir for 3h, added 200ml of water, and heated to 98°C for 15 minutes. Finally, add excess hydrogen peroxide, stir overnight, filter, pickle with 500ml of 5mol / L hydrochloric acid, and then wash with excess water, and dry the obtained sample under freeze-drying conditions for 24 hours.

[0060] (2) Preparation of F-doped graphene: Take 600 mg of graphene oxide, add 300 ml of water and ultrasonically disperse for 1 h. Then add 20ml of hydrofluoric acid solution (40wt.%) a...

Embodiment 2

[0066] Example 2 Preparation of Au-F / CNT composite material using carbon nanotubes and chloroauric acid as raw materials

[0067] (1) Preparation of oxidized carbon nanotubes: Multi-walled carbon nanotubes purchased from Aladdin Reagent Company were used as precursors to prepare oxidized carbon nanotubes. The process was as follows: 5 g of carbon nanotubes were mixed with 60 ml of concentrated nitric acid, and ultrasonicated for 1 h. Afterwards, the mixture was added into the flask, and stirred under reflux at 120° C. for 12 h. After cooling, add a certain amount of KOH to adjust the pH to between 2-7. After cooling and filtering, the material was washed 5 times with deionized water, and then dried overnight in a drying oven at 80° C. to obtain oxidized carbon nanotubes.

[0068] (2) Preparation of F-doped carbon nanotubes: Take 600 mg of oxidized carbon nanotubes, add 300 ml of water and ultrasonically disperse for 1 h. Then add 20ml of hydrofluoric acid solution (40wt.%) a...

Embodiment 3

[0071] Example 3 Preparation of Ru-F / C composite material using activated carbon and ruthenium chloride as raw materials

[0072] (1) Preparation of oxidized activated carbon: The purchased BP2000 activated carbon material was used as the precursor to prepare oxidized activated carbon. The process was as follows: 5g activated carbon was mixed with 60ml concentrated nitric acid, and ultrasonicated for 1h. Afterwards, the mixture was added into the flask, and stirred under reflux at 100° C. for 12 h. After cooling, add a certain amount of KOH to adjust the pH to between 2-7. After cooling and filtering, the material was washed 5 times with deionized water, and then dried overnight in an oven at 80°C to obtain oxidized activated carbon.

[0073] (2) Preparation of F-doped activated carbon: Take 300 mg of oxidized activated carbon, add 150 ml of water and ultrasonically disperse for 1 h. Then add 10ml of hydrofluoric acid solution (40wt.%) and stir evenly. Put the mixture into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com