Metal-loaded carbon-nitride-doped graphene-based flexible non-woven fabric and preparation method and application thereof

A kind of alkenyl flexible and metal-loaded technology, which is applied in chemical instruments and methods, textiles and papermaking, non-woven fabrics, etc., to achieve the effects of easy photoactivity, increased reaction rate, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Inject the graphene oxide aqueous dispersion into a coagulation bath containing 0.05 moles per liter of cobalt nitrate to obtain a graphene oxide hydrogel fiber cross-linked by cobalt ions;

[0040](2) The hydrogel fiber is filtered and washed with a solvent containing cobalt ions. The detergent solvent is a mixed solution of water and ethanol (volume ratio 1:1), and the concentration of cobalt ions in the detergent is 5 times that in the coagulation bath. After drying, obtain a graphene oxide non-woven fabric containing cobalt ions;

[0041] (3) Arrange the above non-woven fabric above the porcelain boat, add urea below, the mass ratio of urea to graphene oxide non-woven fabric is 200:1, then place the porcelain boat in a tube furnace for calcination at 580 degrees Celsius for 2 hours , to obtain a graphene-based flexible nonwoven fabric loaded with cobalt-doped carbon nitride.

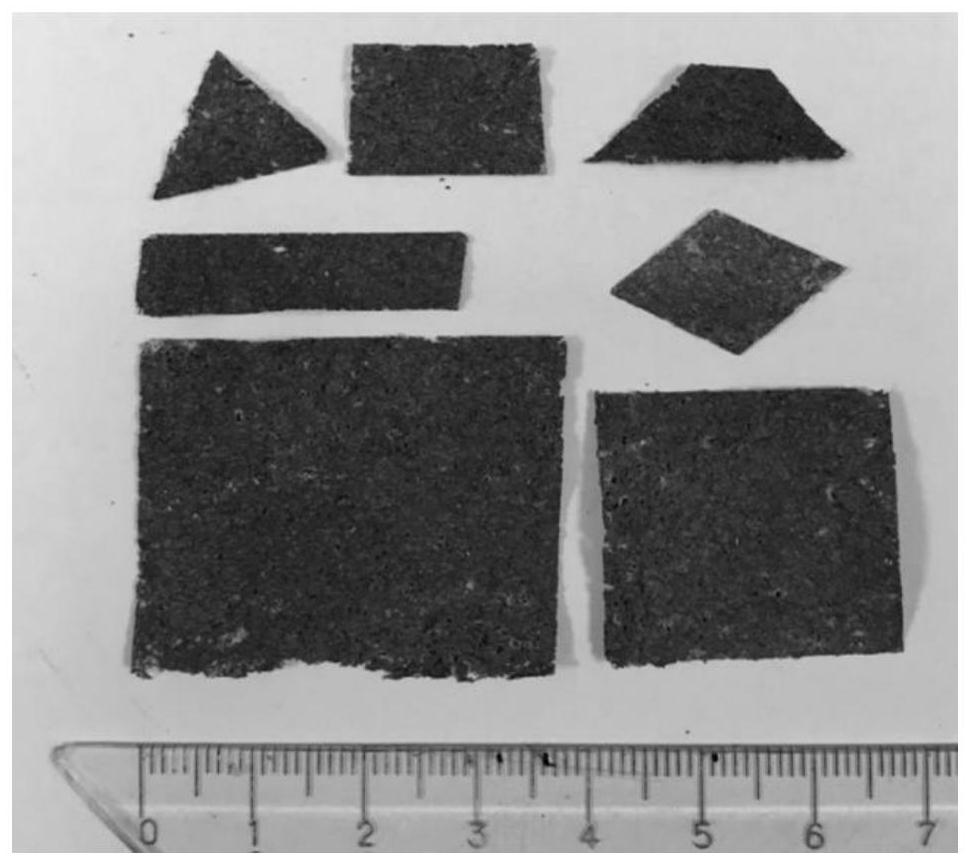

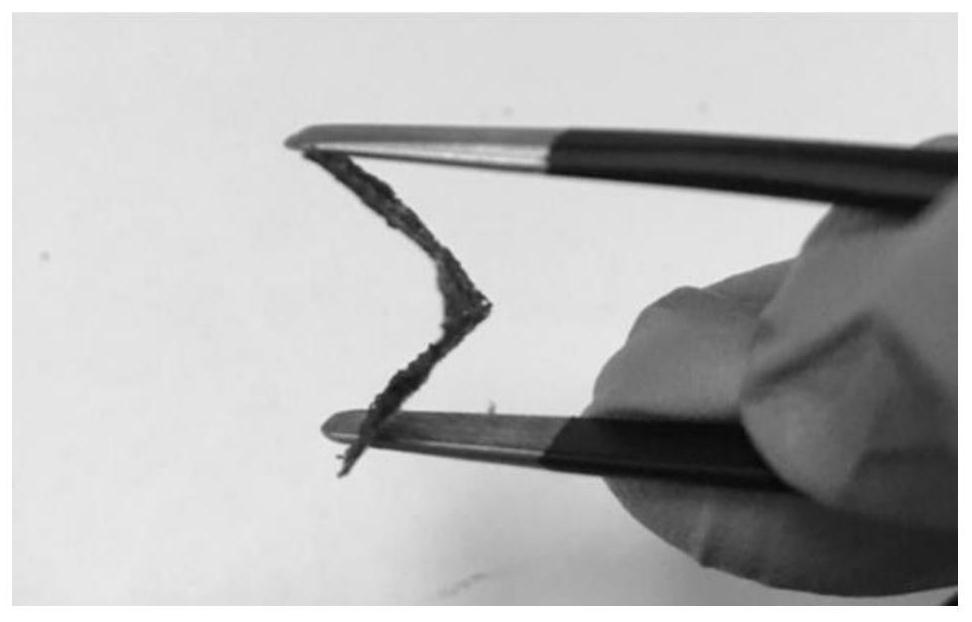

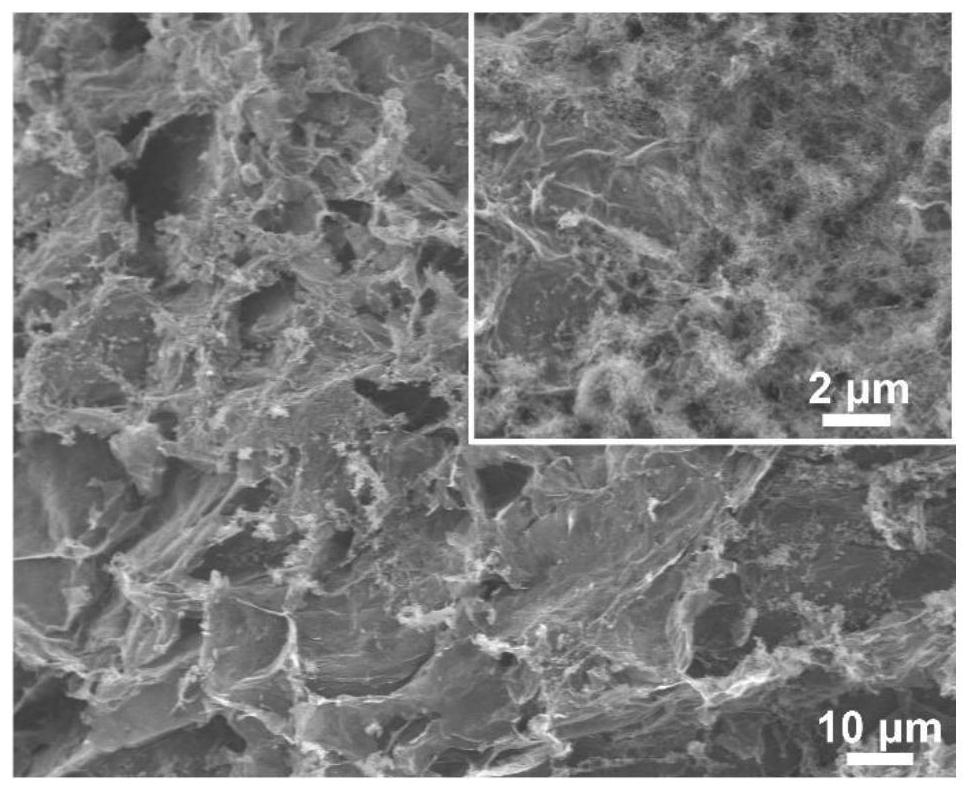

[0042] The appearance of the graphene-based flexible non-woven fabric loaded with cob...

Embodiment 2

[0050] (1) Graphene oxide aqueous dispersion liquid is injected in the coagulation bath containing the zinc nitrate of 0.01 mole per liter, obtains the graphene oxide hydrogel fiber of zinc ion crosslinking;

[0051] (2) The hydrogel fiber is filtered and washed with a solvent containing zinc ions. The detergent solvent is acetone, and the concentration of zinc ions in the detergent is 10 times that in the coagulation bath. After drying, the graphene oxide nonwoven containing zinc ions is obtained. cloth;

[0052] (3) The above-mentioned non-woven is arranged on the top of the porcelain boat, and dicyandiamide is added below, and the mass ratio of dicyandiamide and graphene oxide non-woven fabric is 50:1, and then the porcelain boat is placed in a tube furnace for 550 Calcined for 5 hours in Celsius to obtain a graphene-based flexible non-woven fabric loaded with zinc-doped carbon nitride.

[0053] The zinc-doped carbon nitride-loaded graphene-based flexible non-woven fabric ...

Embodiment 3

[0056] (1) Graphene oxide aqueous dispersion liquid is injected in the coagulation bath containing the nickel nitrate of 0.1 mole per liter, obtains the graphene oxide hydrogel fiber crosslinked by nickel ions;

[0057] (2) The hydrogel fiber is filtered and washed with a solvent containing nickel ions, the detergent solvent is ethanol, the concentration of nickel ions in the detergent is the same as in the coagulation bath, and the graphene oxide nonwoven fabric containing nickel ions is obtained after drying ;

[0058] (3) The above-mentioned non-woven is arranged on the top of the porcelain boat, and cyanamide is added below, and the mass ratio of cyanamide and graphene oxide non-woven fabric is 500:1, and then the porcelain boat is placed in a tube furnace for 600 Celsius and calcined for 0.5 hour to obtain a graphene-based flexible nonwoven fabric loaded with nickel-doped carbon nitride.

[0059] The nickel-doped carbon nitride-loaded graphene-based flexible non-woven fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com