Multifunctional film material and preparation method and application thereof

A thin-film material and multi-functional technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve problems such as inability to separate metal ions, achieve improved flux recovery rate, improved hydrophilicity, and excellent chemical resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of multifunctional thin film material comprises:

[0035] Provide the casting solution obtained by intermittent ultrasonic treatment, the above-mentioned casting solution includes the wetting solution of the catalytic degradation material, the above-mentioned catalytic degradation material is graphene oxide and titanium dioxide; the lateral dimension of the above-mentioned graphene oxide is not more than 3 μm, and the above-mentioned titanium dioxide is anatase Mineral type, particle size is 5-50nm;

[0036] The above-mentioned casting solution is formed in a coagulation bath in the presence of 3,4-dimethoxyphenethylamine and 6-aminocaproic acid to form an oil-water separation base film, the base material of the above-mentioned base film is bisphenol A polysulfone, and the above-mentioned catalytic degradation a material disposed within the base film; and,

[0037] Cross-linking on the surface of the base film to form an active hydrophilic layer, t...

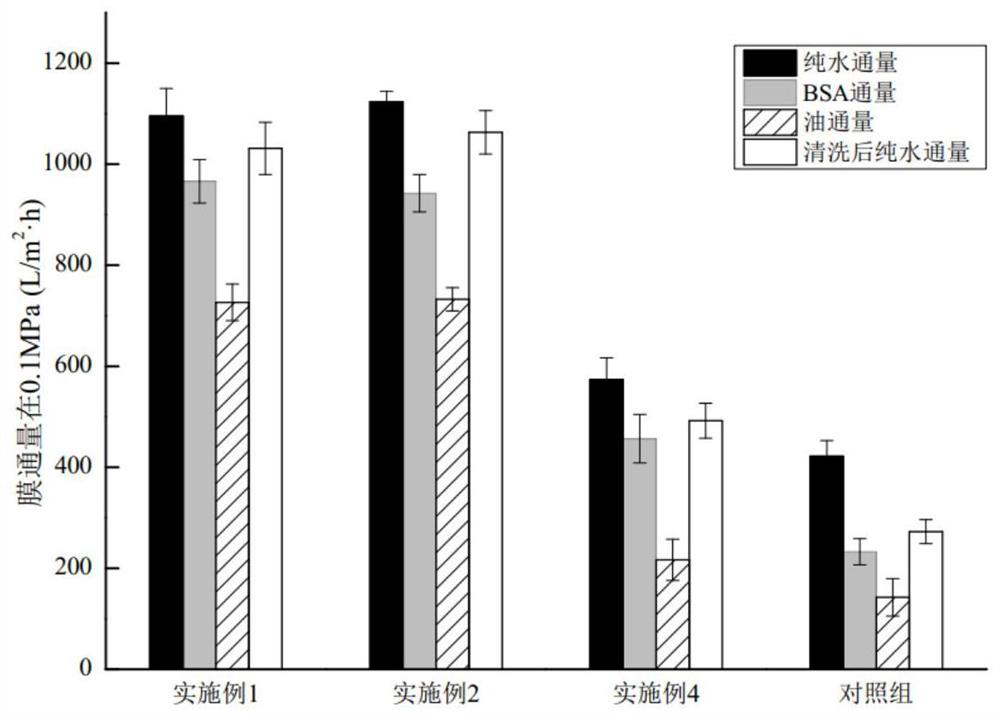

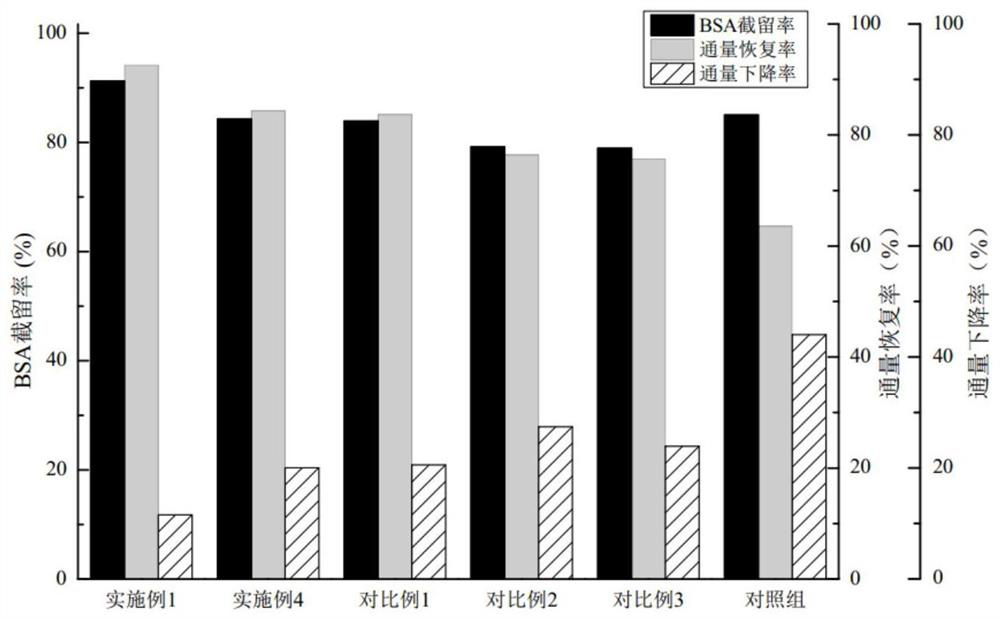

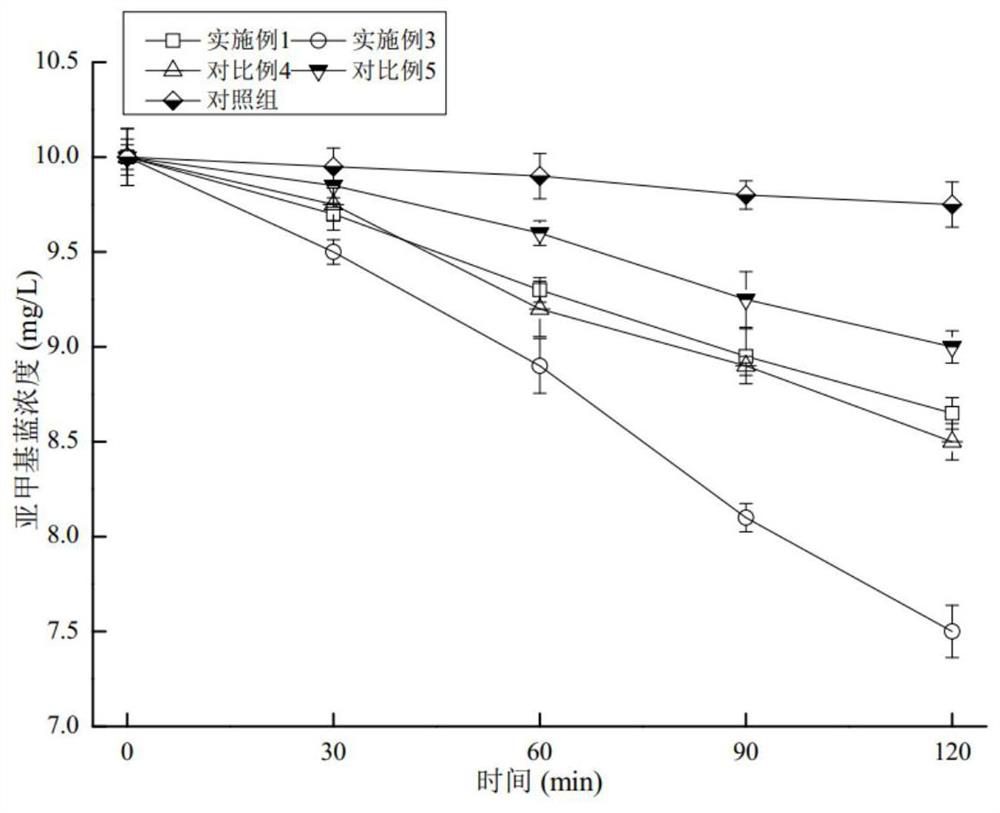

Embodiment 1

[0056] The preparation method of multifunctional film material, comprises the following steps:

[0057] 1) Prepare graphene oxide dispersion and titanium dioxide dispersion with concentrations of 3.5 mg / mL and 2.5 mg / mL respectively using water as solvent, then ultrasonically mix the two dispersions, and then add anhydrous Ethanol, mixing to get the catalytic degradation material wetting solution, the weight ratio of graphene oxide and titanium dioxide in the above mixed solution is 7:1.5, the weight ratio of the mixed solution and absolute ethanol is 1:11, the transverse direction of the above-mentioned graphene oxide The size is 0.3-0.5μm, the number of layers is 10-13 layers, and the particle size of titanium dioxide is 20-30nm;

[0058] 2) Mix the catalytic degradation material wetting solution, additives and solvent morpholine, stir for 1 hour until uniformly dispersed, then add bisphenol A polysulfone dried overnight, ultrasonicate intermittently and mechanically stir fo...

Embodiment 2

[0064] The preparation method of the multifunctional film material of this embodiment is basically consistent with the steps in Example 1, the difference is:

[0065] In step 1), the concentrations of graphene oxide dispersion and titanium dioxide dispersion are 3mg / mL and 3.5mg / mL respectively, and the weight ratio of graphene oxide and titanium dioxide in the mixed solution is 5:1.5, and the transverse dimension of above-mentioned graphene oxide 0.4-0.7μm, the number of layers is 7-11 layers, and the particle size of titanium dioxide is 15-25nm;

[0066] In step 2), the intermittent ultrasonic treatment operating conditions are as follows: the power is 200W, the frequency is 25KHz, every ultrasonic 20min, pause 3min, alternately; wherein wetting liquid, additives, bisphenol A polysulfone and polyethylene glycol 400 The weight proportions in the casting solution are 14.5%, 0.6%, 16.5% and 3% respectively;

[0067] In step 3), the speed of the scraping film is 5m / min, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com