Double-carbon oxygen-carrying copper-cobalt sulfide spinel type carbon material as well as preparation method and application thereof

A spinel-type, copper sulfide technology, applied in chemical instruments and methods, carbon compounds, nanotechnology for materials and surface science, etc., can solve the problems that cannot completely replace noble metal catalysts, and achieve excellent dual-functional performance, Effects of high stability and cycle performance, excellent bifunctional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

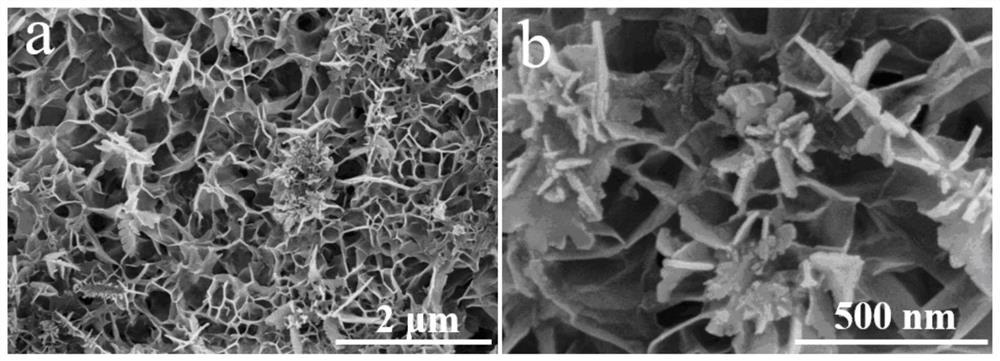

[0036] This embodiment provides a double carbon-supported copper cobalt oxysulfide spinel carbon material ((Cu, Co) 3 OS 3 @CNT-C 3 N 4 ) preparation method, the specific preparation steps are as follows:

[0037] Step 1: Put 5g of urea into a quartz bowl, place it in a muffle furnace, raise the temperature to 550°C at a rate of 2.5°C / min under air conditions, and keep it warm for 3 hours to prepare a light yellow C 3 N 4 spare;

[0038] Step 2: 0.582g Co(NO 3 ) 2 ·6H 2 O and 0.242g Cu(NO 3 ) 2 ·6H 2 O was mixed with 1mL ammonia water, 5mL ethanol and 30mL deionized water, then added 1g sodium sulfide, and ultrasonically dispersed for 30 minutes to obtain a mixed solution;

[0039] Step 3: Add 0.05g C 3 N 4 and 0.05g CNT are added in the polytetrafluoroethylene lining, then add the mixed solution that step 2 obtains in the polytetrafluoroethylene lining;

[0040] Step 4: Put the polytetrafluoroethylene lining into the hydrothermal reaction kettle, use an oven to he...

Embodiment 2

[0044] This embodiment provides a double carbon-supported copper cobalt oxysulfide spinel carbon material ((Cu, Co) 3 OS 3 @CNT-C 3 N 4 ) preparation method, the specific preparation steps are as follows:

[0045] Step 1: Put 5g of urea into a quartz bowl, place it in a muffle furnace, raise the temperature to 550°C at a rate of 2.5°C / min under air conditions, and keep it warm for 3 hours to prepare a light yellow C 3 N 4 spare;

[0046] Step 2: 0.582g Co(NO 3 ) 2 ·6H 2 O and 0.242g Cu(NO 3 ) 2 ·6H 2 O was mixed with 1mL of ammonia water, 5mL of ethanol and 30mL of deionized water, and then 1g of sulfur powder was added, and the mixed solution was obtained after ultrasonic dispersion for 30 minutes;

[0047] Step 3: Add 0.05g C 3 N 4 and 0.05g CNT are added in the polytetrafluoroethylene lining, then add the mixed solution that step 2 obtains in the polytetrafluoroethylene lining;

[0048] Step 4: Put the polytetrafluoroethylene lining into the hydrothermal react...

Embodiment 3

[0054] This embodiment provides a double carbon-supported copper cobalt oxysulfide spinel carbon material (CuCo 2 S 4 @C 3 N 4 -CNT) preparation method, concrete preparation steps are as follows:

[0055] Step 1: Put 5g of urea into a quartz bowl, place the quartz bowl in a muffle furnace, raise the temperature to 550°C at a rate of 2.5°C / min under air conditions, and keep it warm for 3 hours to prepare light yellow C 3 N 4 spare;

[0056] Step 2: 0.582g Co(NO 3 ) 2 ·6H 2 O and 0.242g Cu(NO 3 ) 2 ·6H 2 O was mixed with 1mL ammonia water, 5mL ethanol and 30mL deionized water, then added 1g sodium thiosulfate, and ultrasonically dispersed for 30 minutes to obtain a mixed solution;

[0057] Step 3: Add 0.05g C 3 N 4 and 0.05g CNT are added in the polytetrafluoroethylene lining, then add the mixed solution that step 2 obtains in the polytetrafluoroethylene lining;

[0058] Step 4: Put the polytetrafluoroethylene lining into the hydrothermal reaction kettle, use an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com