Preparation method of gallium oxide film based on Zn and N co-doping

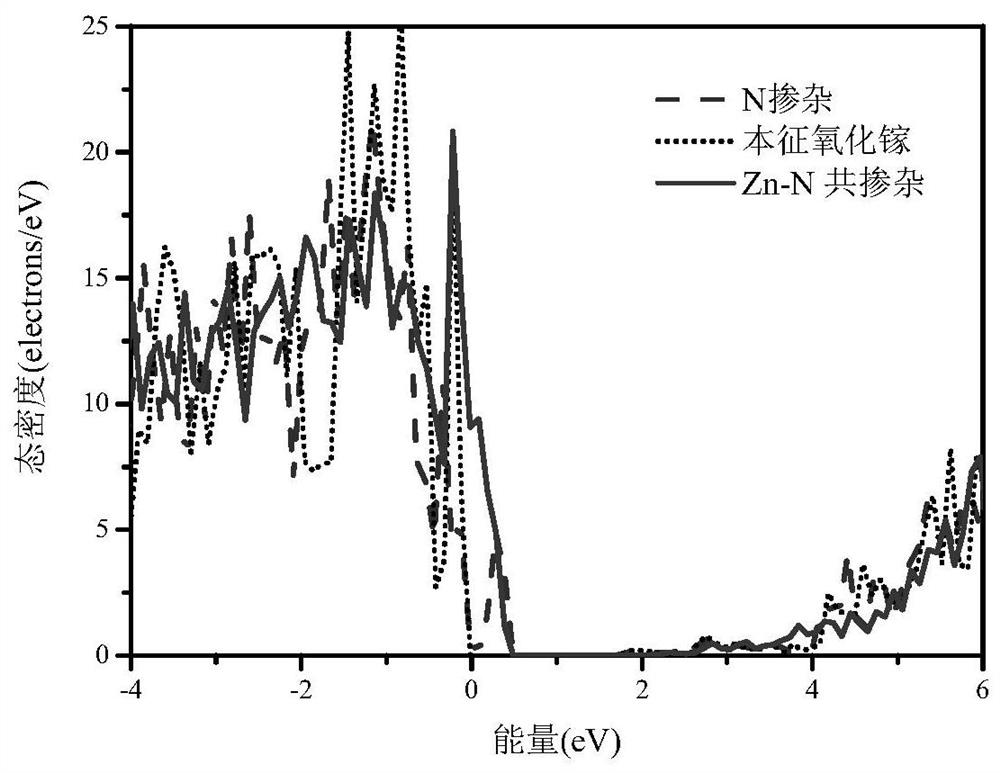

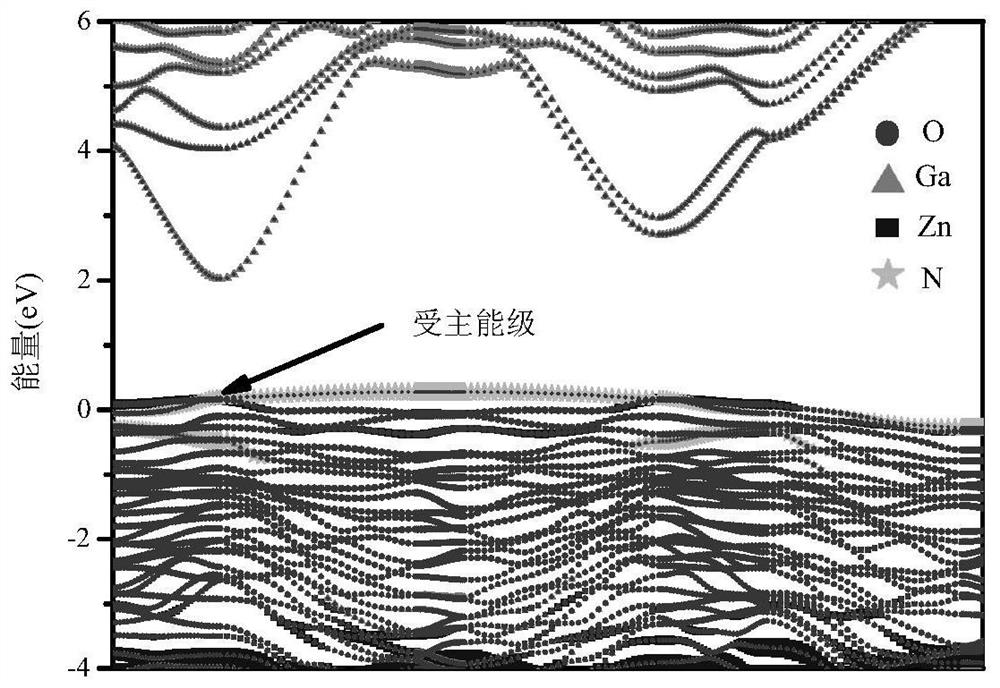

A thin-film preparation and gallium oxide technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of introduction, reduction of p-type gallium oxide hole carrier mobility, deep impurity energy level, etc. Achieve high chemical stability, reduce impurity formation energy, and good p-type characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

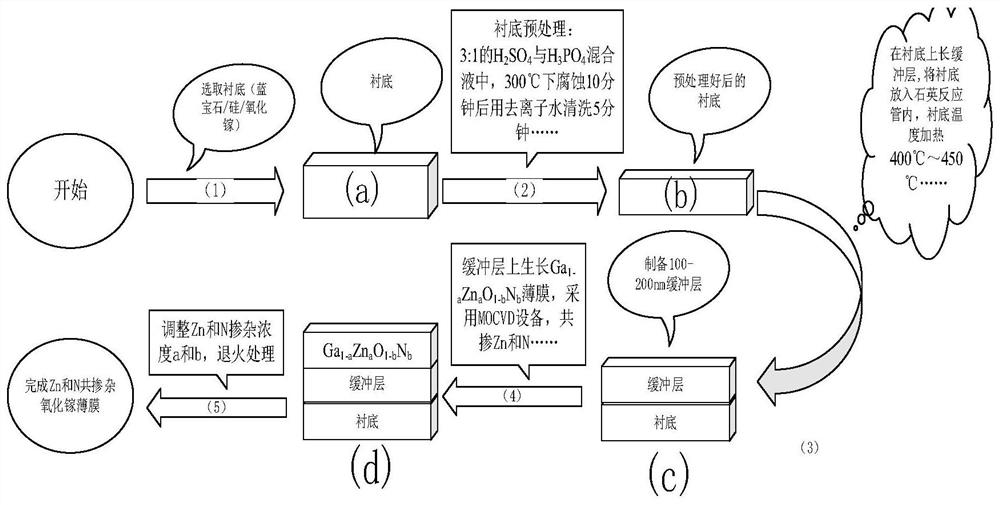

[0025] Example 1: Preparation of a gallium oxide thin film with sapphire as a substrate and Zn and N doping concentrations of 0.125 and 0.083, respectively.

[0026] Step 1: Choose sapphire as the substrate, such as figure 1 (a).

[0027] In the second step, the sapphire substrate is pretreated for cleaning and etching.

[0028] 2.1) The sapphire substrate was ultrasonically cleaned in acetone for 10 minutes, then the substrate was ultrasonically cleaned in absolute ethanol for 10 minutes, and then rinsed repeatedly with deionized water for 3 times; then it was placed in 3:1 H 2 SO 4 with H 3 PO 4 In the mixed solution, corrode at 300°C for 10 minutes and then wash with deionized water for 5 minutes;

[0029] 2.2) heat-treat the cleaned substrate at a temperature of 1380° C. in a hydrogen H2 atmosphere for 1 hour to obtain a pretreated sapphire substrate, such as figure 1 (b).

[0030] Step 3: Grow 150nm thick Ga on sapphire substrate 2 o 3 The buffer layer.

[0031]...

Embodiment 2

[0040] Example 2: Preparation of gallium oxide thin films with 6H-SiC substrate and Zn and N doping concentrations of 0.0417 and 0.0625, respectively.

[0041] Step 1: Select 6H-SiC as the substrate.

[0042] Step 2: Perform cleaning and etching pretreatment on the 6H-SiC substrate.

[0043] The specific realization of this step is the same as that of the second step of Embodiment 1.

[0044] Step 3: Grow 100nm thick Ga on 6H-SiC substrate 2 o 3 The buffer layer.

[0045] Put the pretreated substrate into the reaction chamber first, turn on the vacuum pump to evacuate the reaction chamber to 10 -2 Pa. Using Ga(C 2 h 5 ) 3 and O 2 As Ga source and O source respectively, the temperature of the source bottle is maintained at -10°C to 20°C through a semiconductor cold trap, the inert gas Ar is used as the carrier gas, and high-purity He is used as the auxiliary gas flow;

[0046] Then heat the substrate, stop for 1min every time the temperature rises by 50°C, and heat th...

Embodiment 3

[0053] Embodiment 3: Prepare a gallium oxide thin film with a gallium oxide substrate, and the doping concentrations of Zn and N are 0.031 and 0.021, respectively.

[0054] Step A: Gallium oxide is selected as the substrate.

[0055] Step B: performing cleaning and etching pretreatment on the gallium oxide substrate.

[0056] The specific realization of this step is the same as that of the second step of Embodiment 1.

[0057] Step C: Grow 200nm thick Ga 2 o 3 The buffer layer.

[0058] C1) Put the pretreated substrate into the reaction chamber, turn on the vacuum pump to evacuate the reaction chamber to 5×10 -3 Pa. Using Ga(C 2 h 5 ) 3 and O 2 As Ga source and O source respectively, the temperature of the source bottle is maintained at -10°C to 20°C through a semiconductor cold trap, the inert gas Ar is used as the carrier gas, and high-purity He is used as the auxiliary gas flow;

[0059] C2) Heating the substrate, stopping for 1 minute every time the temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com