Absorbable barrier film and preparation method thereof

A technology of barrier membrane and collagen membrane, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of unsatisfactory bone repair effect, insufficient vertical bone augmentation, poor mechanical properties, etc., which is conducive to the growth of bone regeneration cells. good bone repair effect and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

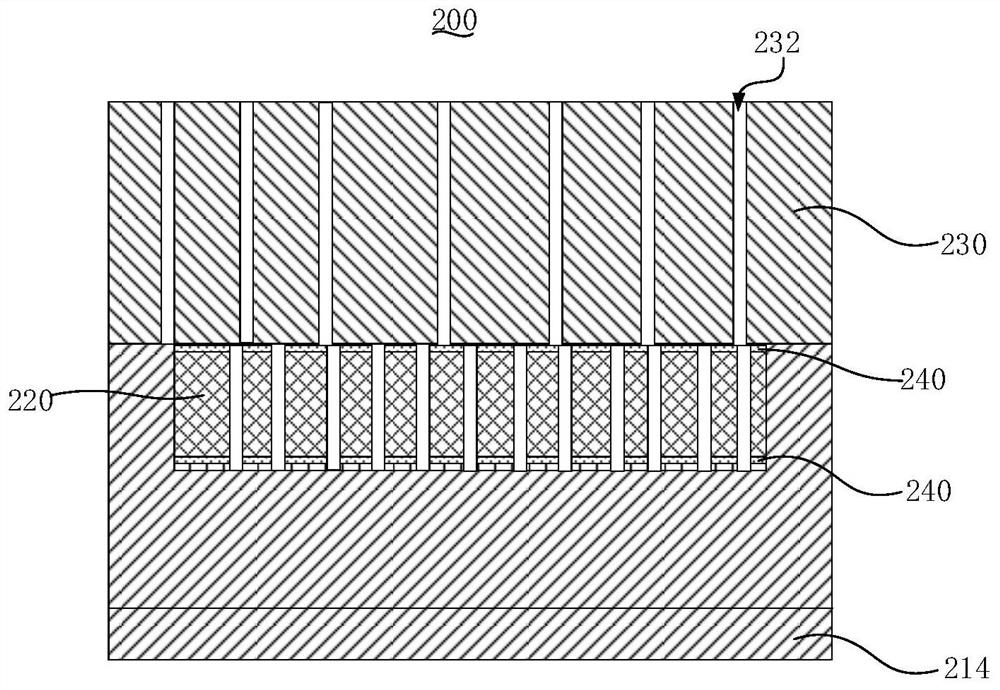

[0057] At this time, the preparation method of the second collagen film 230 includes the following steps: decellularizing, degreasing and dehydrating the animal tissue to obtain collagen; pulverizing the collagen to obtain collagen powder; dispersing the collagen powder in water to obtain Dispersion liquid; heating the dispersion liquid at 40°C to 50°C to obtain collagen fiber slurry; coating the collagen fiber slurry on the modified layer 240 of the magnesium alloy layer 220, and drying to obtain a porous second Collagen Membrane 230. At this time, the second communication hole 232 extends from a side of the second collagen film 230 away from the magnesium alloy layer 220 to a side close to the magnesium alloy layer 220 . In order to reduce the degradation rate of the second collagen film 230 , after coating the collagen fiber slurry on the modified layer 240 of the magnesium alloy layer 220 , the drying method is dehydrogenation heat treatment.

[0058] In this embodiment, ...

Embodiment 1

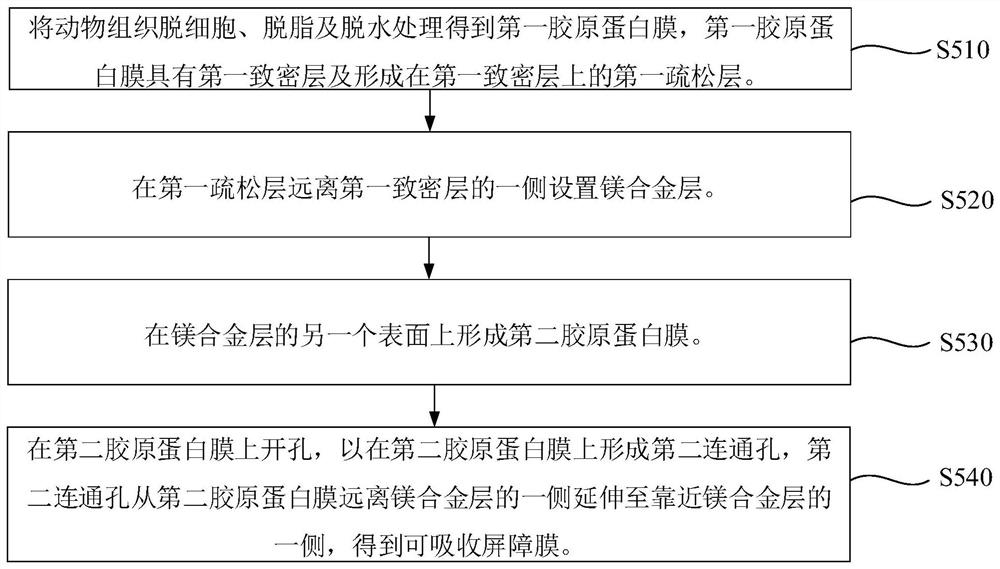

[0087] The preparation process of the absorbable barrier film of this embodiment is as follows:

[0088] (1) Prepare the magnesium alloy layer: punch holes on the magnesium alloy sheet to form the first connected hole on the magnesium alloy sheet to obtain the magnesium alloy layer, wherein the aperture of the first connected hole is 0.8 millimeters, and the thickness of the magnesium alloy layer is 0.4 mm. mm, the elemental composition of the magnesium alloy layer is magnesium, aluminum, manganese and copper.

[0089] (2) Coating a modified product on the surface of the magnesium alloy layer, the modified product being chitosan.

[0090] (3) Wash the animal tissue (pig's pericardium) 4 times with pure water, soak the animal tissue in a hydrogen peroxide solution with a mass percentage concentration of 3% for 1 hour, and then use a mass percentage concentration of 2% Sodium hydroxide solution soaked for 12 hours, then soaked in 1% hydrochloric acid for 6 hours, then transferr...

Embodiment 2

[0097] The preparation process of the absorbable barrier film of this embodiment is as follows:

[0098] (1) Prepare the magnesium alloy layer: punch holes on the magnesium alloy sheet to form the first connected hole on the magnesium alloy sheet to obtain the magnesium alloy layer. The aperture of the first connected hole is 0.5 mm, and the thickness of the magnesium alloy layer is 0.1 mm. The constituent elements of the magnesium alloy layer are magnesium, calcium, aluminum, silver, copper and manganese.

[0099] (2) Coating a modified product on the surface of the magnesium alloy layer, the modified product being gelatin.

[0100](3) Wash the animal tissue (cow's pleura) 3 times with pure water, soak the animal tissue in 0.1% peracetic acid solution by mass percentage for 1 hour, and then use 4% hydrogen Soak in potassium oxide solution for 1 hour, then immerse in 0.05% acetic acid solution for 12 hours, then transfer the animal tissue to 0.05% pepsin solution for 48 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com