A kind of highly stable organic lead iodide crystal material and its preparation method and application

A high-stability, crystalline material technology, applied in the growth of polycrystalline materials, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of narrow photoresponse range and inability to effectively use sunlight Energy and photocatalytic applications are limited, and achieve the effects of wide light absorption range, high crystallinity, and simple and easy-to-operate preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Material synthesis: Weigh 0.23g of lead oxide, 0.57g of disodium adipate and 0.5g of potassium iodide into a reaction kettle (20mL in volume) containing 15mL of deionized water, then add 250μL of concentrated hydrochloric acid dropwise, and stir vigorously to obtain uniform suspension; seal the autoclave and place it in an oven with a constant temperature of 180°C for 72 hours; after the reaction is completed, lower the temperature of the oven to room temperature at a rate of 5°C / hour; The product was transferred to a beaker, washed three times with deionized water and ethanol, and finally dried in a vacuum oven at 60° C. for 12 hours to obtain the material.

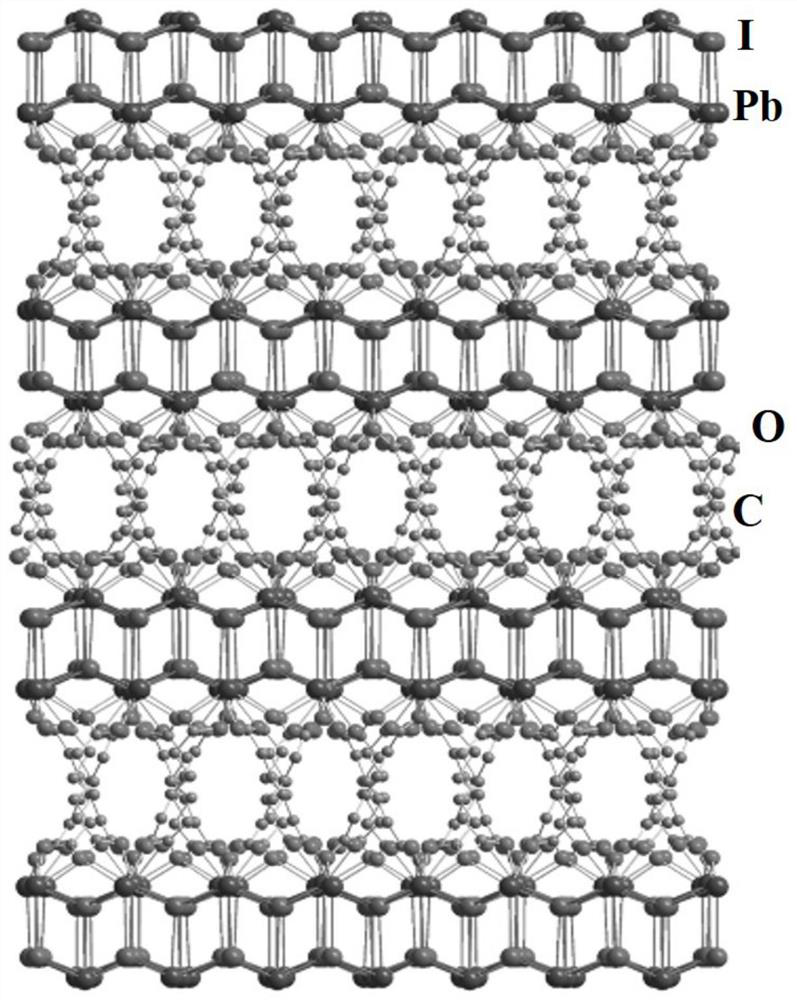

[0036]The properties of the material obtained in this example are yellow transparent crystals, confirmed by single crystal ray diffraction, the crystal structure of the material is as follows figure 1 shown.

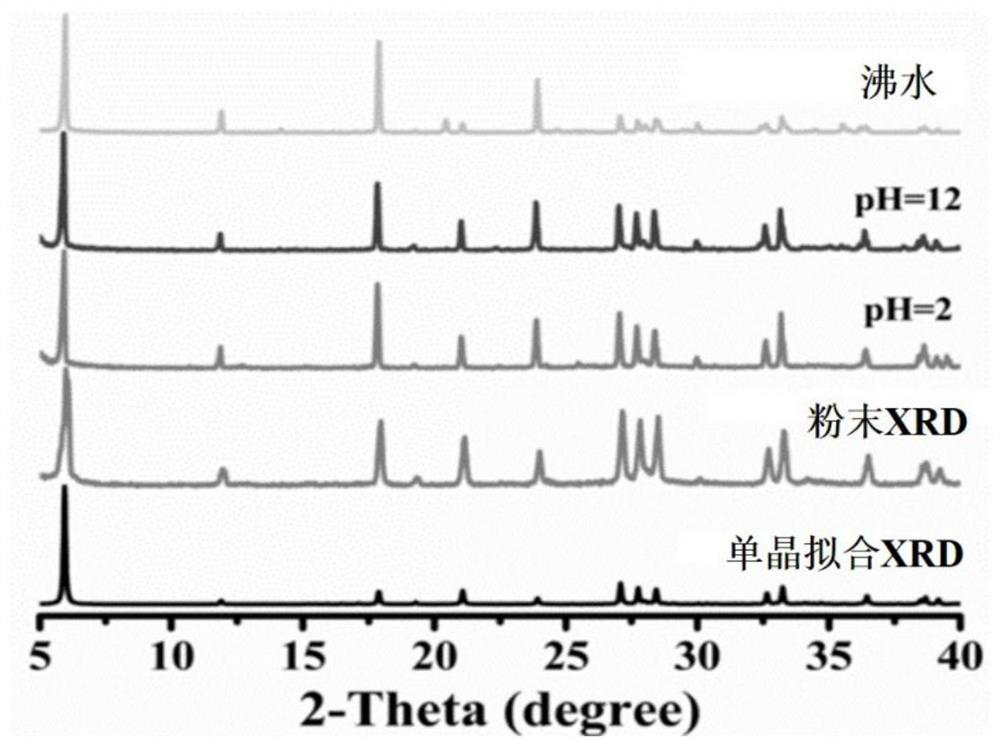

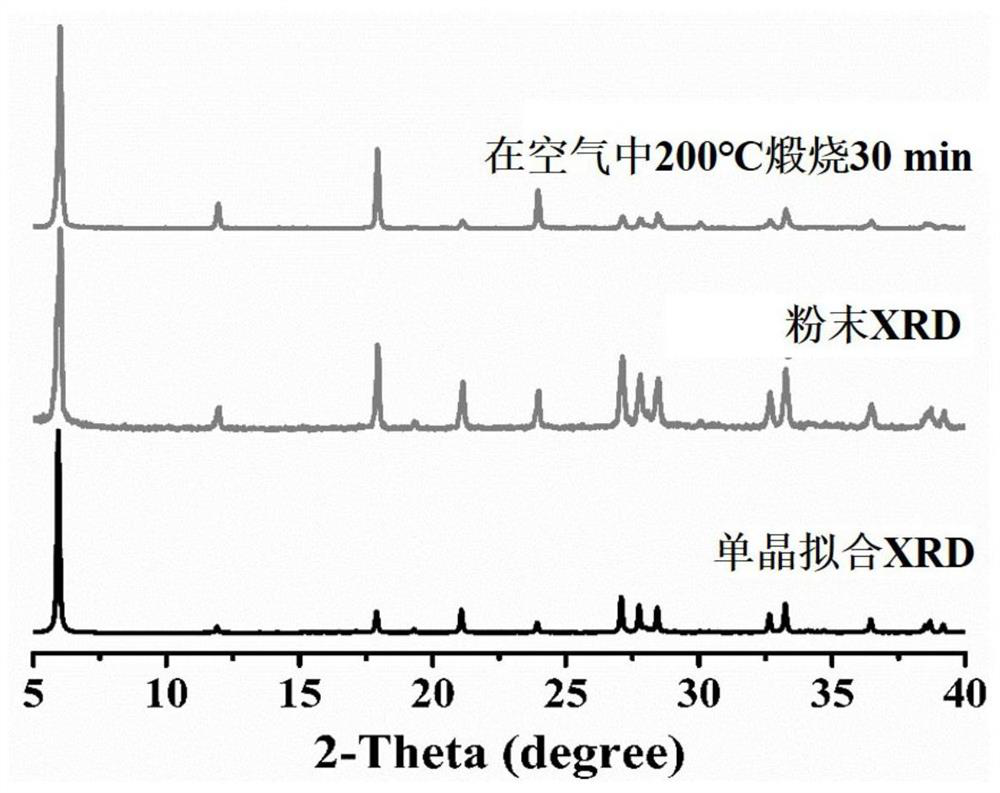

[0037] Material [Pb 2 I 2 (H 2 O) 0.75 ] 2+ [ – o 2 C(CH 2 ) 4 CO 2 – ] Stability investigati...

Embodiment 2

[0064] Material synthesis: Weigh 0.23g of lead oxide, 0.475g of disodium adipate and 0.5g of potassium iodide into a reaction kettle (20mL in volume) containing 15mL of deionized water, then add 230μL of concentrated hydrochloric acid dropwise, and stir vigorously to obtain uniform suspension; seal the autoclave and place it in an oven with a constant temperature of 180°C for 72 hours; after the reaction is completed, lower the temperature of the oven to room temperature at a rate of 5°C / hour; The product was transferred to a beaker, washed three times with deionized water and ethanol, and finally dried in a vacuum oven at 60° C. for 12 hours to obtain the material.

Embodiment 3

[0066] Material synthesis: Weigh 0.23g of lead oxide, 0.76g of disodium adipate and 0.5g of potassium iodide into a reaction kettle (20mL in volume) containing 15mL of deionized water, then add 275μL of concentrated hydrochloric acid dropwise, and stir vigorously to obtain uniform suspension; seal the autoclave and place it in an oven with a constant temperature of 180°C for 72 hours; after the reaction is completed, lower the temperature of the oven to room temperature at a rate of 5°C / hour; The product was transferred to a beaker, washed three times with ethanol, and finally dried in a vacuum oven at 60° C. for 12 hours to obtain the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com